Manufacturing method and system for Sichuan cuisine-savory meat loaf

A production method and meat cake technology, which are applied in the industrial production system of Sichuan cuisine fragrant bowl meat, and the industrial production field of Sichuan cuisine fragrant bowl meat, can solve the problems of easy falling off of egg layer, thin egg layer, poor taste, etc., and achieve excellent taste , the surface is smooth and smooth, the effect of high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

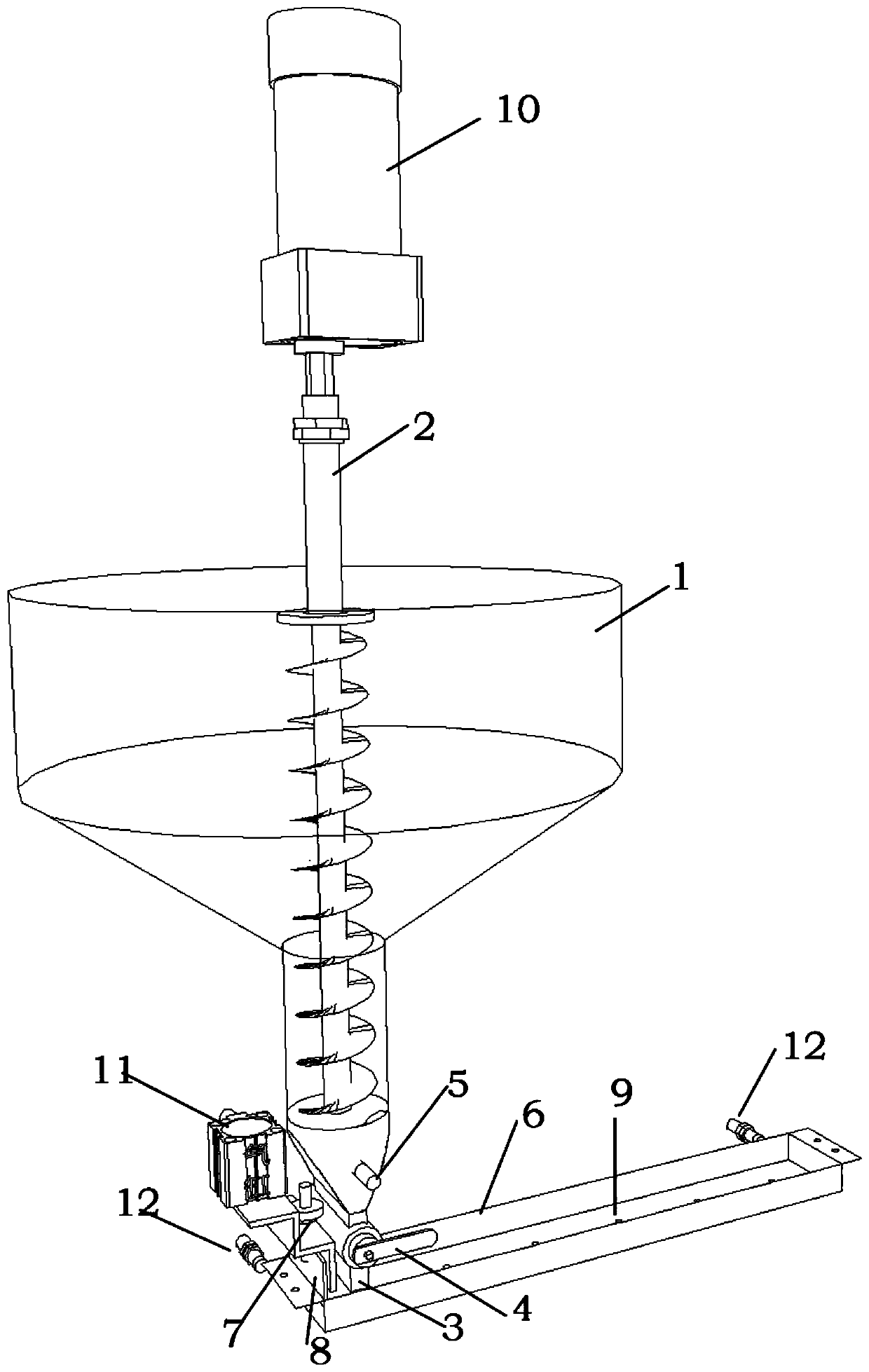

Image

Examples

Embodiment 1

[0030] Use a meat grinder to make fatty meat and lean meat mixed with fat and lean meat, the mass ratio of fat meat and lean meat is 0.45:1, separate the egg white and egg yolk of the egg, and set aside.

[0031] Add starch, edible salt, and carrageenan to the raw egg yolk, stir well to form a paste, add 150g of starch, 45g of edible salt, and 10g of carrageenan per kilogram of raw egg yolk; steam half of the paste-like raw egg yolk at 90-100°C for 30 minutes The cooked egg yolk is obtained, and after cooling, it is pulverized into particles with a particle diameter of 1-2mm, and then the cooked egg yolk particles are stirred evenly with the other half of the paste-like raw egg yolk to obtain mayonnaise.

[0032]Add egg white, ginger and onion juice, starch, edible salt, sodium glutamate, and carrageenan to the meat paste, add 180g egg white, 18g ginger and onion juice, 130g starch, 10g edible salt, and 4.0g glutamic acid per kilogram of meat paste sodium nitrate, 3.5g carrage...

Embodiment 2

[0035] Use a meat grinder to make fatty meat and lean meat mixed with fat and lean meat, the mass ratio of fat meat and lean meat is 0.45:1, separate the egg white and egg yolk of the egg, and set aside.

[0036] Add starch, edible salt, and carrageenan to the raw egg yolk, stir well to form a paste, add 150g of starch, 42g of edible salt, and 9g of carrageenan per kilogram of raw egg yolk; steam half of the paste-like raw egg yolk at 90-100°C for 25 minutes The cooked egg yolk is obtained, and after cooling, it is pulverized into particles with a particle diameter of 1-2mm, and then the cooked egg yolk particles are stirred evenly with the other half of the paste-like raw egg yolk to obtain mayonnaise.

[0037] Add egg white, ginger and onion juice, starch, edible salt, sodium glutamate, and carrageenan to the meat paste, add 180g egg white, 18g ginger and onion juice, 130g starch, 10g edible salt, and 4.0g glutamic acid per kilogram of meat paste sodium nitrate, 3.5g carrage...

Embodiment 3

[0040] Use a meat grinder to make fatty meat and lean meat mixed with fat and lean meat, the mass ratio of fat meat and lean meat is 0.45:1, separate the egg white and egg yolk of the egg, and set aside.

[0041] Add starch, edible salt, and carrageenan to the raw egg yolk, stir well to form a paste, add 150g of starch, 45g of edible salt, and 10g of carrageenan per kilogram of raw egg yolk; steam half of the paste-like raw egg yolk at 90-100°C for 30 minutes The cooked egg yolk is obtained, and after cooling, it is pulverized into particles with a particle diameter of 1-2mm, and then the cooked egg yolk particles are stirred evenly with the other half of the paste-like raw egg yolk to obtain mayonnaise.

[0042] Add egg white, ginger and onion juice, starch, edible salt, sodium glutamate, and carrageenan to the meat paste, add 180g egg white, 18g ginger and onion juice, 130g starch, 10g edible salt, and 4.0g glutamic acid per kilogram of meat paste sodium nitrate, 3.5g carrag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com