Quick tensioning device for prestressed anchor rods and construction method

A tensioning device and prestressing technology, applied in infrastructure engineering, construction, sheet pile walls, etc., can solve problems such as different screw pitches, and achieve the effects of avoiding slippage, reducing equipment costs, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

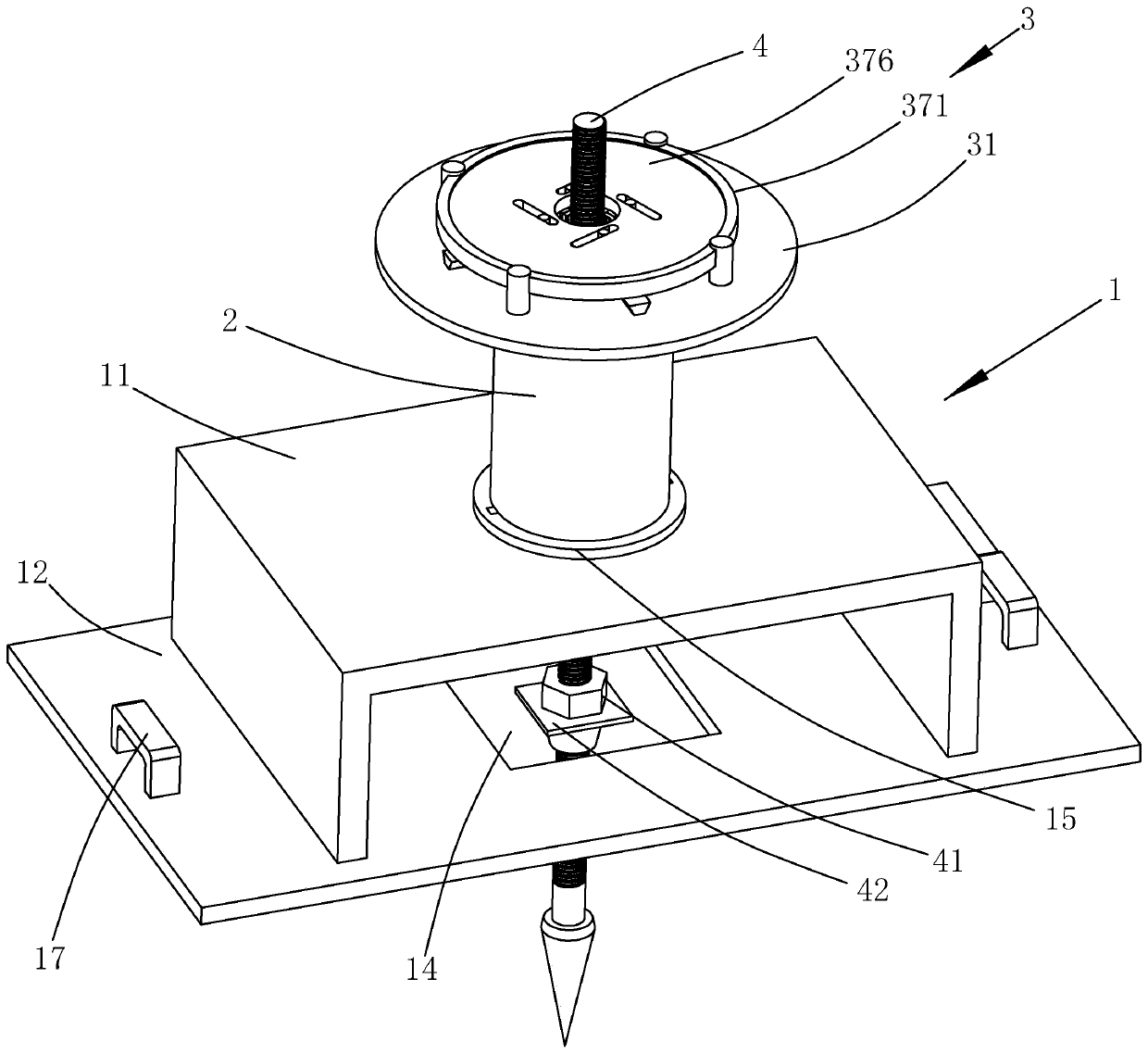

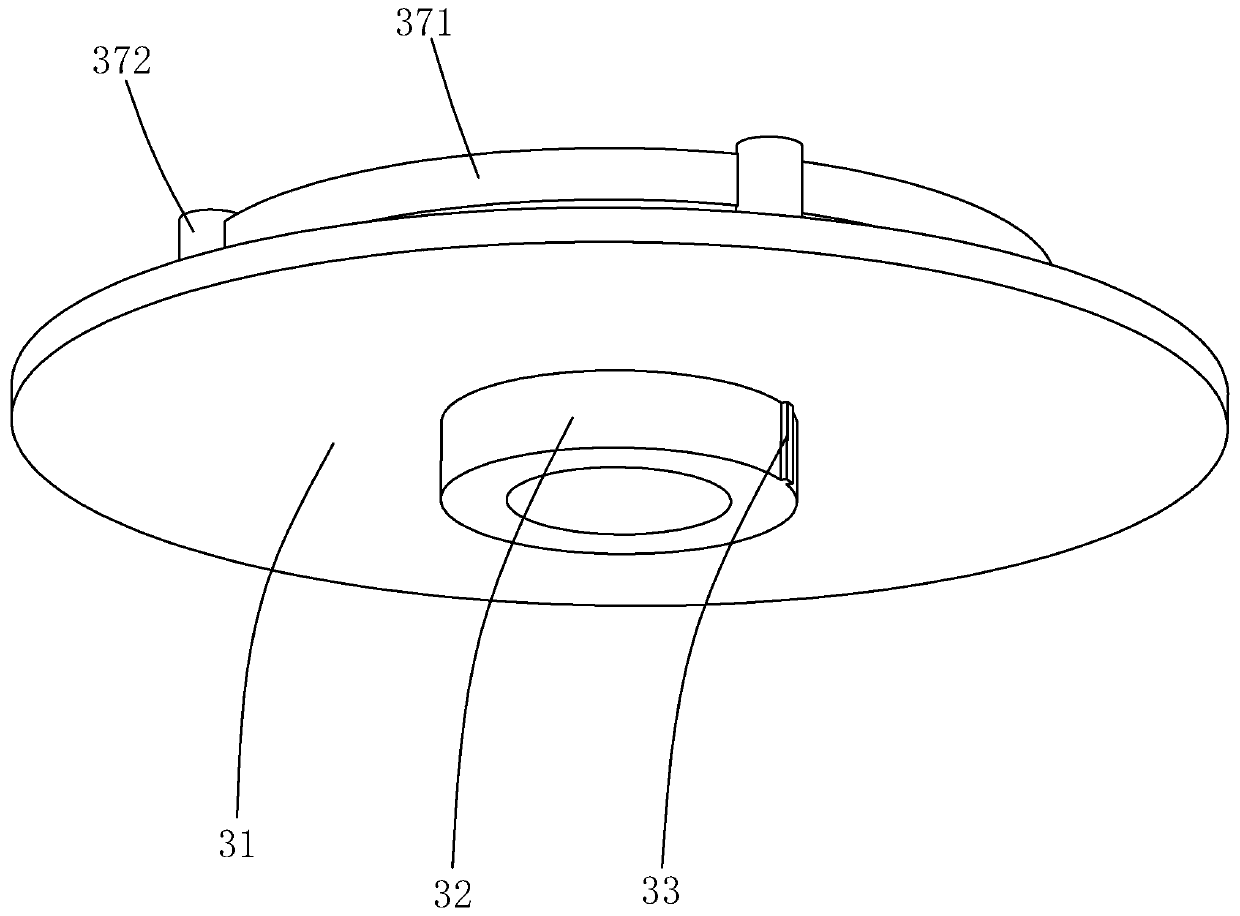

[0045] refer to figure 1 , is a prestressed fast tensioning device for anchor rods disclosed in the present invention, which can perform tension work on anchor rods 4 of different specifications, with relatively small limitations. The prestressed anchor fast tensioning device includes a base 1, a piercing cylinder 2 arranged on the base 1, and a locking mechanism arranged on the top of the piercing cylinder 2 for connecting the piston barrel of the piercing cylinder 2 with the anchor rod 4 3.

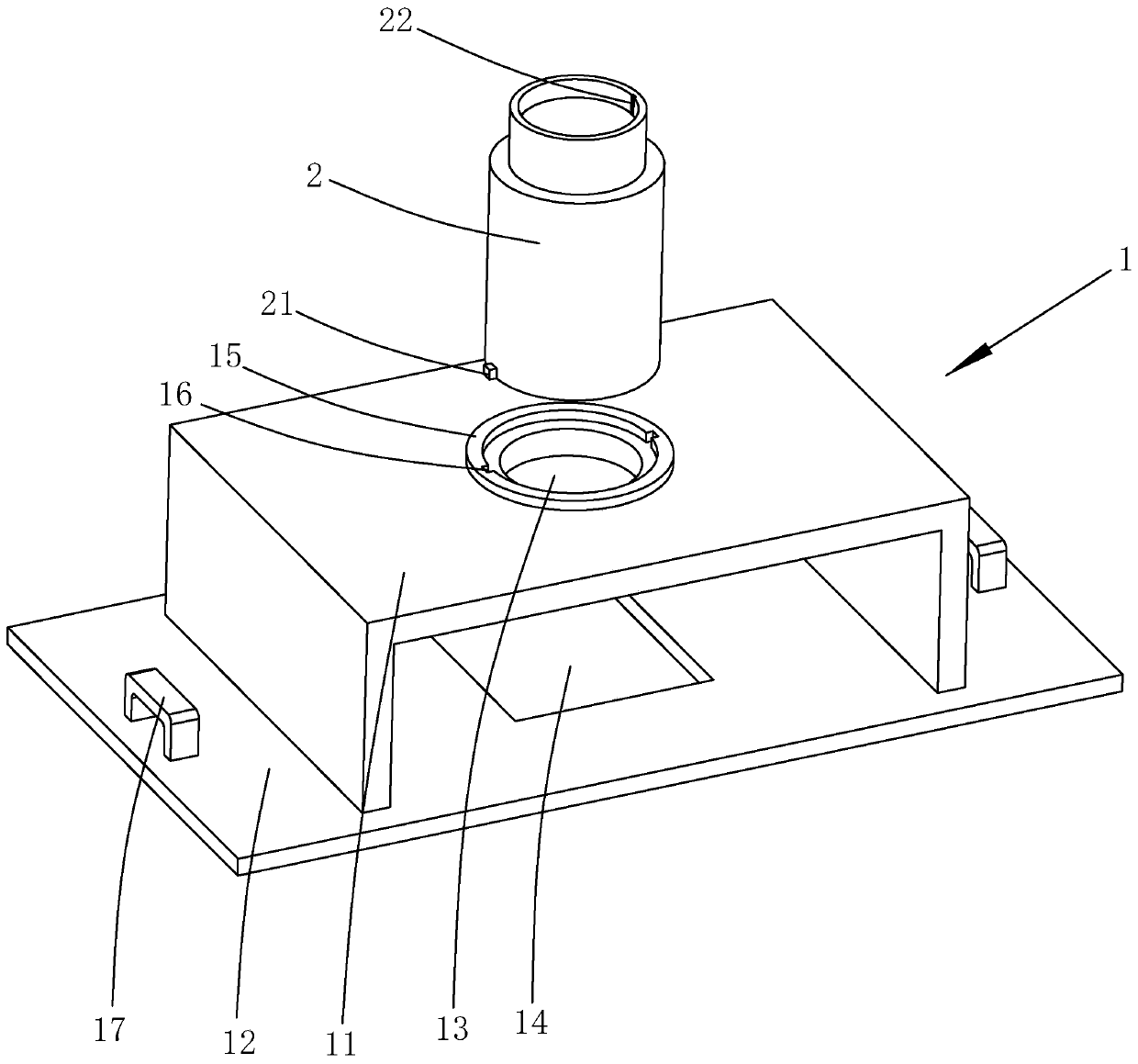

[0046] refer to figure 2, the base 1 includes a base plate 12 and a U-shaped plate 11, the U-shaped plate 11 is buckled upside down in the middle of the upper side of the base plate 12 and the two ends of the U-shaped plate 11 are welded to the base plate 12, and a first through hole is opened at the center of the U-shaped plate 11 13. A second through hole 14 is provided at a position corresponding to the first through hole 13 on the base plate 12, and the first through hole 13 and ...

Embodiment 2

[0055] A fast tensioning method for an anchor rod 4, using the prestressed fast tensioning device for an anchor rod disclosed in Embodiment 1 to perform some steps, the method includes the following steps:

[0056] Step 1. Use a drilling rig to drill holes in the ground;

[0057] Step 2, placing the anchor rod 4: place the anchor rod 4 at the center of the borehole to ensure that the anchor rod 4 is concentric with the borehole, and perform concrete grouting in the borehole;

[0058] Step 3: Apply prestress to the anchor rod 4 after the concrete grouting is solidified: first put the backing plate 42 on the anchor rod 4; then screw the nut 41 onto the backing plate 42; then put the base 1 on the anchor rod 4 Then put the threading oil cylinder 2 on the base 1 and make the anchor rod 4 pass through the threading oil cylinder 2; then open the drive assembly 37 so that the splint 36 hugs the anchor rod 4; then control the threading oil cylinder 2 to extend, to Pull the anchor rod...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap