Slope Surface Treatment Method of Mine Dump

A treatment method and technology for dumping sites, applied in botany equipment and methods, excavation, construction, etc., can solve problems such as soil pollution, affecting social stability around the mine, local people's normal production and life, physical health, and water pollution. To achieve the effect of avoiding natural disasters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

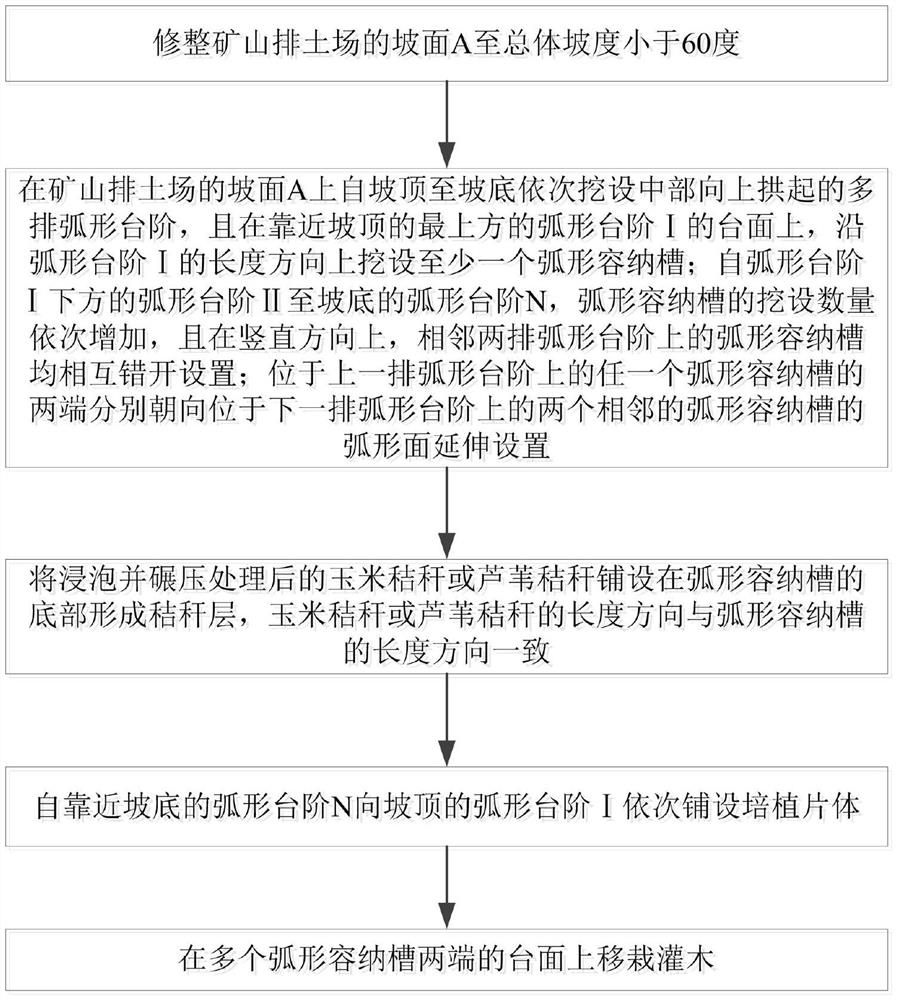

[0057] The invention provides a slope treatment method for a mine dump, comprising the following steps:

[0058] A slope treatment method for a mine dump, comprising the following steps:

[0059] Step 1, trimming the slope A of the mine dump site 100 until the overall slope is less than 60 degrees; for example, it can be 55 degrees, 50 degrees or 45 degrees;

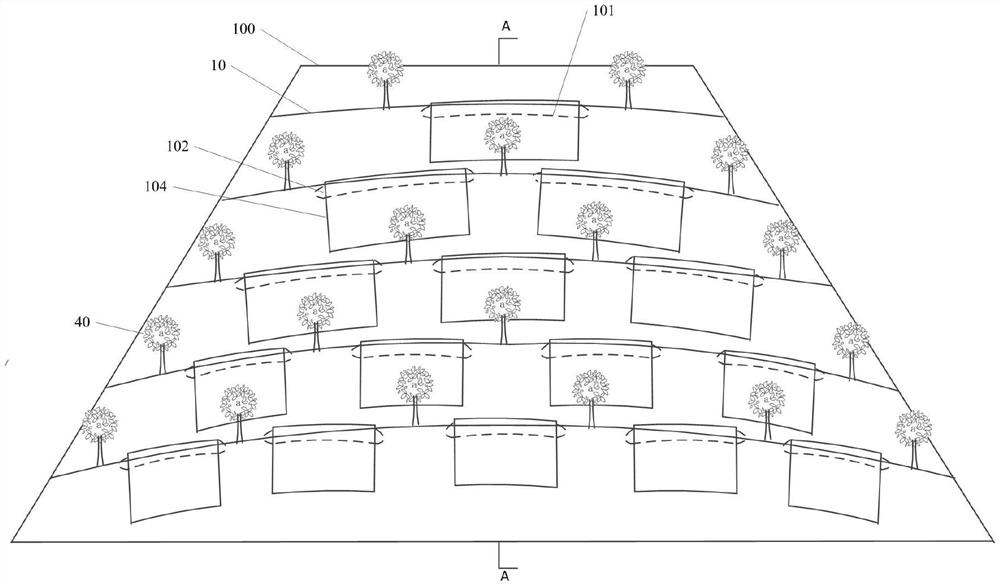

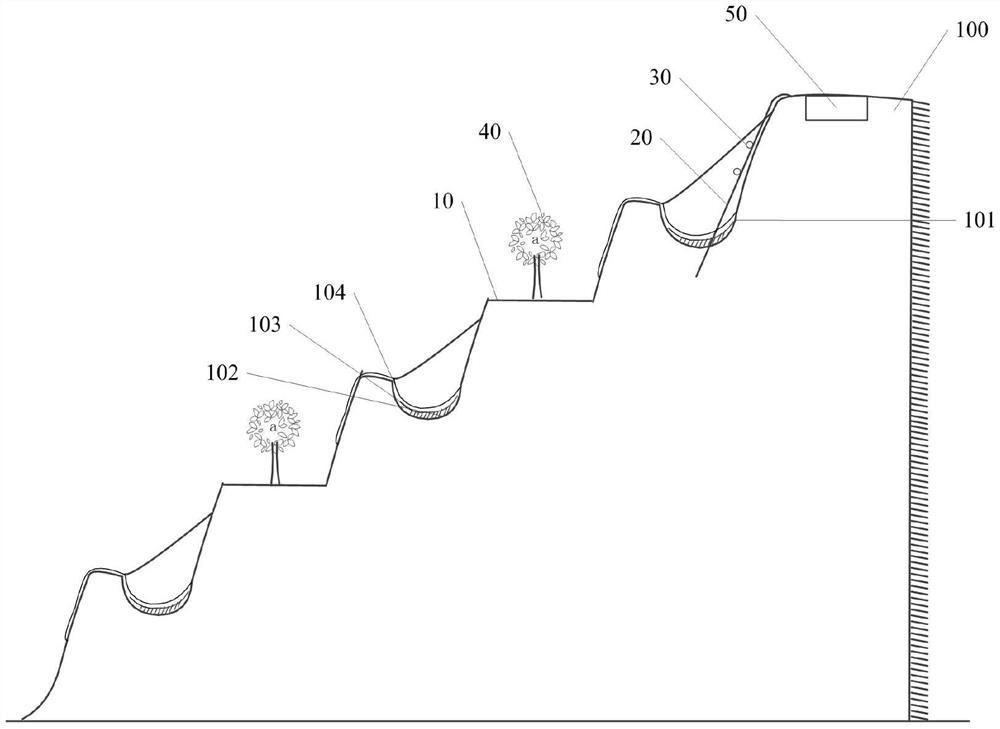

[0060] Step 2: On the slope A of the mine dump, excavate successively from the top of the slope to the bottom of the slope, and set up multiple rows of arc-shaped steps 10 with the middle part arched upwards, and on the platform of the uppermost arc-shaped step I near the top of the slope , along the length direction of the arc-shaped step I, at least one arc-shaped accommodation groove 101 is dug; from the arc-shaped step II below the arc-shaped step I to the arc-shaped step N at the bottom of the slope, the number of arc-shaped accommodation grooves 102 is excavated in order increase, and in the vertical direction, th...

Embodiment 2

[0075] The invention provides a slope treatment method for a mine dump, comprising the following steps:

[0076] A slope treatment method for a mine dump, comprising the following steps:

[0077] Step 1, trimming the slope A of the mine dump site 100 until the overall slope is less than 60 degrees; for example, it can be 55 degrees, 50 degrees or 45 degrees;

[0078] Step 2: On the slope A of the mine dump, excavate successively from the top of the slope to the bottom of the slope, and set up multiple rows of arc-shaped steps 10 with the middle part arched upwards, and on the platform of the uppermost arc-shaped step I near the top of the slope , along the length direction of the arc-shaped step I, at least one arc-shaped accommodation groove 101 is dug; from the arc-shaped step II below the arc-shaped step I to the arc-shaped step N at the bottom of the slope, the number of arc-shaped accommodation grooves 102 is excavated in order increase, and in the vertical direction, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com