Building wall surface plastering device and use method

A technology for building walls and walls, applied in the direction of construction, building structure, etc., can solve the problems of low work efficiency and high labor intensity, and achieve the effect of improving efficiency and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

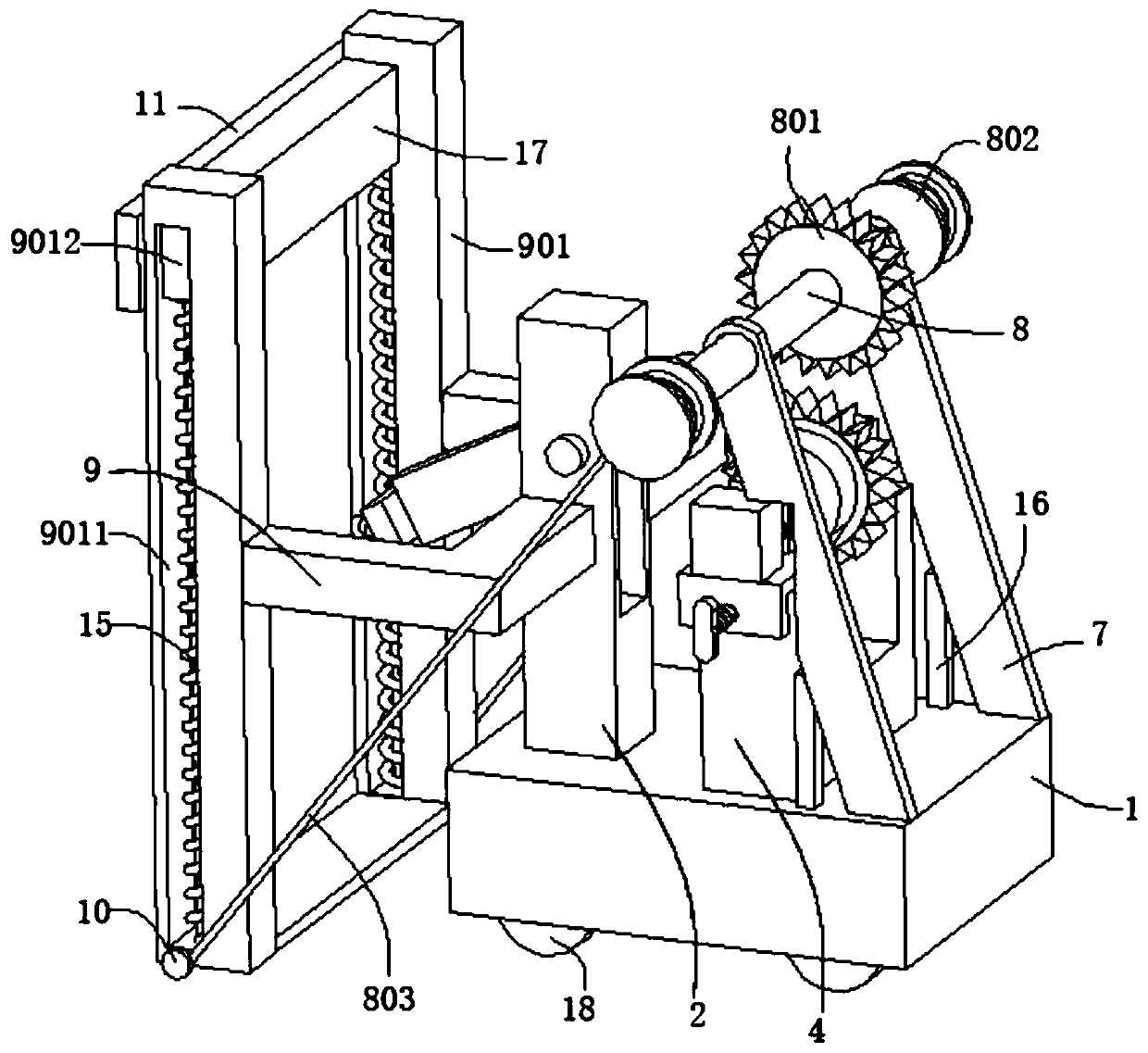

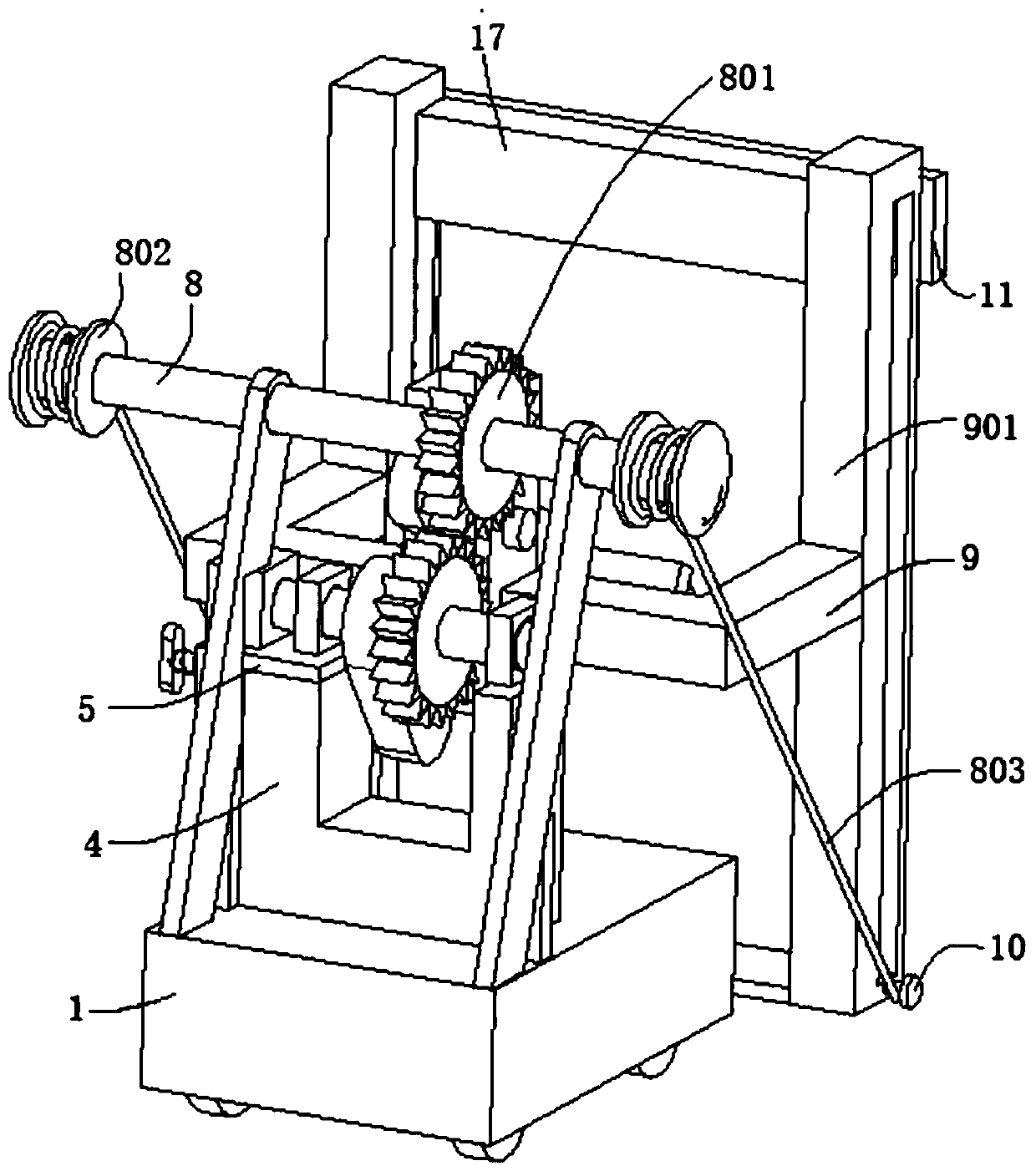

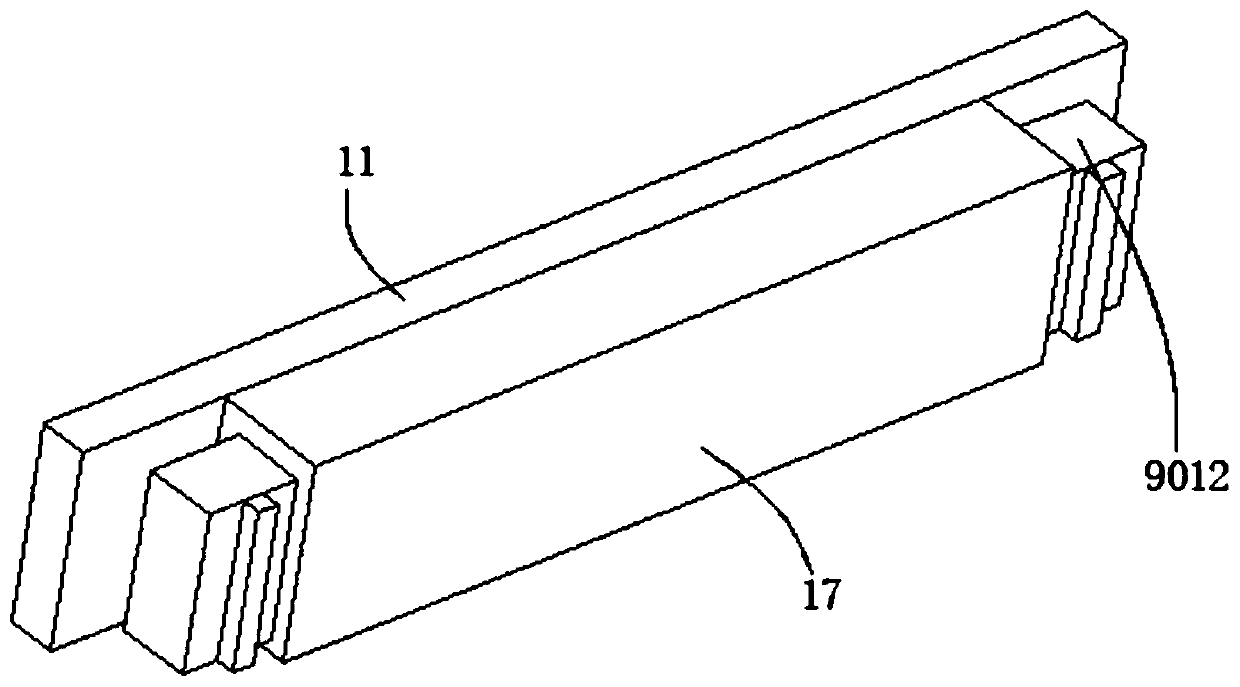

[0036] refer to Figure 1-7, a plastering device for the surface of a building wall, comprising a base 1, the outer wall of the base 1 is connected with a fixed block 2, the outer wall of the fixed block 2 is dug with a groove 201, and the inner wall of the groove 201 is connected with a rotating shaft 202, The outer wall of the rotating shaft 202 is connected with a swing rod 203, the outer wall of the swing rod 203 is connected with a spray head 3, the top of the base 1 is connected with a workbench 4, and the outer wall of the workbench 4 is slidably connected with a moving plate 5. The outer wall of the moving plate 5 is fixedly connected with a motor 6, the output end of the motor 6 is connected with a first rotating shaft 601, and the outer wall of the first rotating shaft 601 is connected with a cam 602, and the cam 602 is movable against the swing rod 203, and the base 1 The outer walls of both sides are connected with supporting plates 7, and the second rotating shaft...

Embodiment 2

[0039] refer to Figure 3-8 , a plastering device and method of use on the surface of a building wall, which are basically the same as in Embodiment 1, furthermore, the outer wall of the moving plate 5 is connected with a first fixed plate 13, and the first rotating shaft 601 is rotatably connected to the first fixed plate 13 Inside, the outer wall of the workbench 4 is connected with a second fixed plate 14, and the first rotating shaft 601 is rotatably connected in the second fixed plate 14; by setting the first fixed plate 13 and the second fixed plate 13 on the top of the movable plate 5 and the workbench 4 respectively. The plate 14 facilitates guiding and fixing the rightward movement of the first rotating shaft 601 .

[0040] The outer wall of the workbench 4 is connected with a guide rail 20, and the inner wall of the guide rail 20 is slidably connected with a slider 19, and the slider 19 is fixedly connected to the bottom wall of the mobile plate 5; Inside the guide ...

Embodiment 3

[0045] refer to figure 1 , figure 2 , Figure 5 and Figure 7 , a method of using a plastering device on the surface of a building wall, which is basically the same as that of Embodiment 1, furthermore, the bottom wall of the groove 201 is connected with a first elastic element 204, and the first elastic element 204 is far away from the bottom of the groove 201 One end of the wall is connected to the outer wall of the swing rod 203; after the cam 602 squeezes the swing rod 203, the swing rod 203 drives the nozzle 3 down slowly and at a constant speed, so that the nozzle 3 sprays the wall evenly, thereby improving the smoothing effect.

[0046] The invention also discloses a method for using a plastering device on the surface of a building wall, which specifically includes the following steps:

[0047] S1: Before the device works, it is necessary to connect the hose of the spraying machine to the nozzle 3, and then move the device to the construction position through the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com