A screw vacuum pump temperature control device

A technology for temperature control devices and vacuum pumps, which is applied to components of pumping devices for elastic fluids, pumps, rotary piston type/swing piston type pump components, etc., which can solve the problems of high difficulty in installation and maintenance, increased costs, Problems such as fast motor rotation frequency, achieve the effect of disassembly and installation speed and stability, fast disassembly and installation speed, and avoid overheating and shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

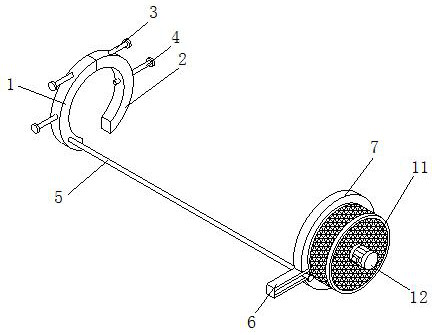

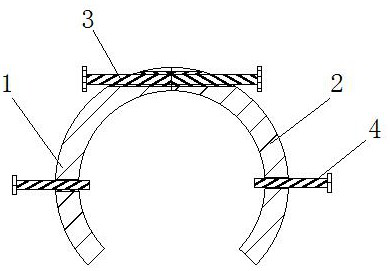

[0043] Example 1: Please refer to Figure 1-4 , a screw-type vacuum pump temperature control device, comprising a left fixed ring 1, a right fixed ring 2 and a cooling ring 7, the left fixed ring 1 and the right fixed ring 2 are fan-shaped, the concave surfaces of the left fixed ring 1 and the right fixed ring 2 Corresponding to left and right, threaded holes are provided on the side tops of the left fixing ring 1 and right fixing ring 2, and the screw threads of the threaded holes on the side tops of the left fixing ring 1 and right fixing ring 2 are opposite in direction, and the left fixing ring 1 and the right fixing ring 2 are on the top sides of the top. The threaded hole of the threaded hole is threadedly connected with the outer walls on both sides of a double-ended screw rod 3. First, the double-ended screw rod 3 is turned to make the distance between the left fixed ring 1 and the right fixed ring 2 longer, and then the space between the left fixed ring 1 and the right...

Embodiment 2

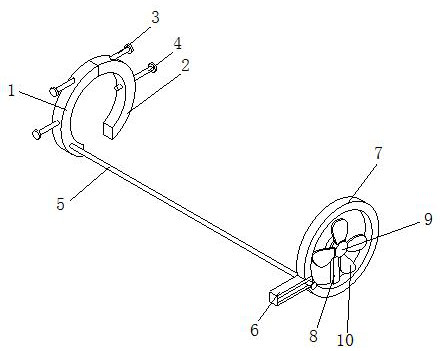

[0045] Embodiment 2: Please refer to the fixed ring 5-8 on the left in the figure. On the basis of Embodiment 1, an annular groove 14 is provided on the back side of the cooling ring 7. The annular groove 14 is an annular groove, and a slider is sleeved in the annular groove 14 B15, the material of the slider B15 is a magnet and is adsorbed in the ring groove 14. The back side of the slider B15 is provided with a word protrusion 16, and the outer wall of the word protrusion 16 is sleeved with a board 17, and the shape of the board 17 is The fan-shaped body, the front of the plug board 17 is provided with a slot 18, the slot 18 is in the shape of a line and is socketed with the protrusion 16 of the line, at first, according to the installation environment of the vacuum pump and the device, a certain number of Slider B15, then on the slider B15, insert the board 17 through the socket of the in-line protrusion 16 and the slot 18, and make the concave surface of the board 17 corres...

Embodiment 3

[0048] Embodiment 3: Please refer to the left fixing ring 9-16 in the figure. On the basis of Embodiment 2, the top surface of the insert plate 17 is provided with mounting holes 41 on both sides of the air outlet 21, and the inner wall of the mounting hole 41 is fixedly connected with Liquid-filled bag 42, liquid-filled bag 42 is a hollow ellipsoid and made of silica gel material, the top surface of cooling ring 7 is fixedly connected with liquid inlet box 22, the top surface of liquid inlet box 22 is hollowed out, and liquid inlet box 22 Sixteen liquid inlet ports 25 are fixedly connected to the back side of the body, and the liquid inlet ports 25 communicate with the inside of the liquid inlet tank 22. The nozzles of the liquid inlet ports 25 are fixedly equipped with pipe covers, and the liquid filling bag 42 is close to one end of the liquid inlet tank 22. The top surface is fixedly connected and communicated with a liquid pipe 27. First, fill the liquid coolant in the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com