Electro-hydraulic servo valve overlap rapid pneumatic measurement gas circuit and measurement method

An electro-hydraulic servo valve and pneumatic measurement technology, which is applied in the direction of servo motor assembly, fluid pressure actuation system test, fluid pressure actuation device, etc. Uncertain relative position and other problems, to achieve the effect of ensuring accuracy, short measurement time and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following will further explain how the present invention is implemented in conjunction with the accompanying drawings and specific implementation methods.

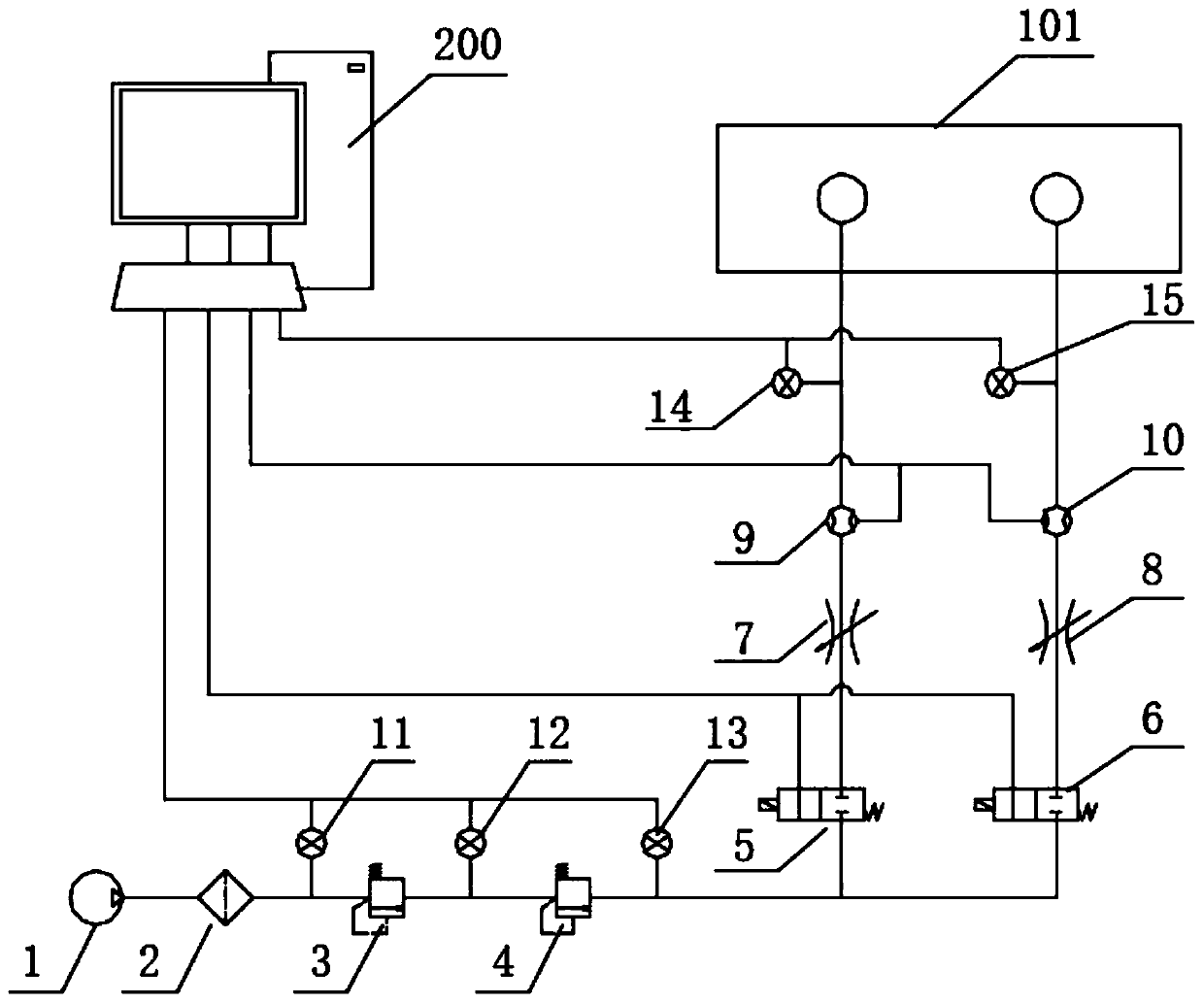

[0046] refer to figure 1 As shown, the present invention provides an electro-hydraulic servo valve fast pneumatic measurement gas path, including a gas source 1, a filter 2, a gas pressure reducing valve 3, a precision pressure reducing valve 4, a first solenoid valve 5, The second solenoid valve 6, the first throttle valve 7, the second throttle valve 8, the first flow sensor 9 and the second flow sensor 10; wherein, the air outlet of the air source 1 communicates with the air inlet of the filter 2, The air outlet of the filter 2 communicates with the air inlet of the gas decompression valve 3, the air outlet of the gas decompression valve 3 communicates with the air inlet of the prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com