High-beam and low-beam integrated LED type vehicle lamp

An integrated, far and near light technology, applied in the field of vehicle lighting, can solve the problems of increasing the complexity of lens group products, complex light source technology of laser lens group, reducing reliability and stability, etc., so as to achieve stable lighting effect and avoid heat Accumulation, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described:

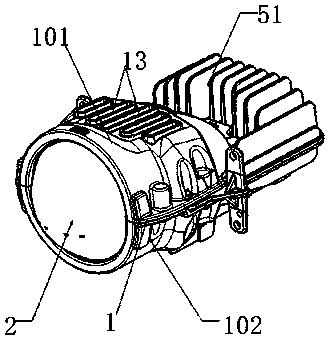

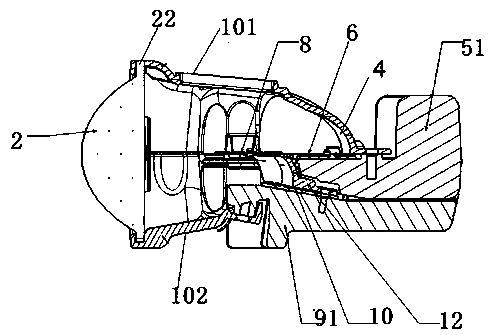

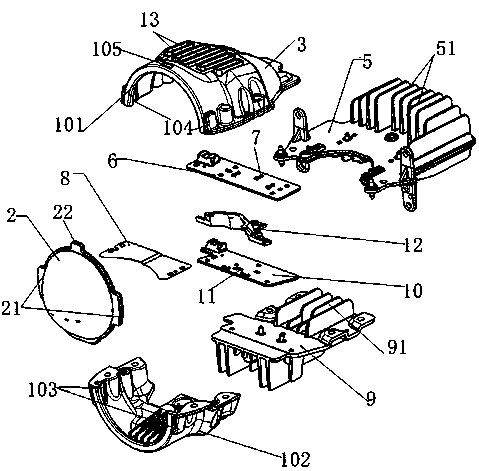

[0020] Such as Figure 1 to Figure 5 As shown, the far and near beam integrated vehicle lamp includes a housing 1, the housing 1 is composed of a semicircular upper housing 101 and a lower housing 102, and the upper housing 101 and the lower housing 102 can be snapped together , the two can be fixed by reserving bolt holes on the upper and lower shells, and then using bolts.

[0021] After the upper case 101 and the lower case 102 are fastened together, the front ends fit together to form a circle, and a first arc-shaped groove 103 is left at the front end of the lower case, and a second arc-shaped groove is left at the corresponding position of the upper case. Groove 104, the first arc-shaped groove 103 and the second arc-shaped groove 104 are combined to form a lens mounting groove, and the lens 2 is provided with a mounting plate 21 corresponding to the first arc-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com