Microwave steam engine device

A steam engine and microwave technology, applied in the field of power machinery, can solve problems such as increased greenhouse effect, energy loss, poisoning, etc., and achieve the effects of reduced production costs, high conversion efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

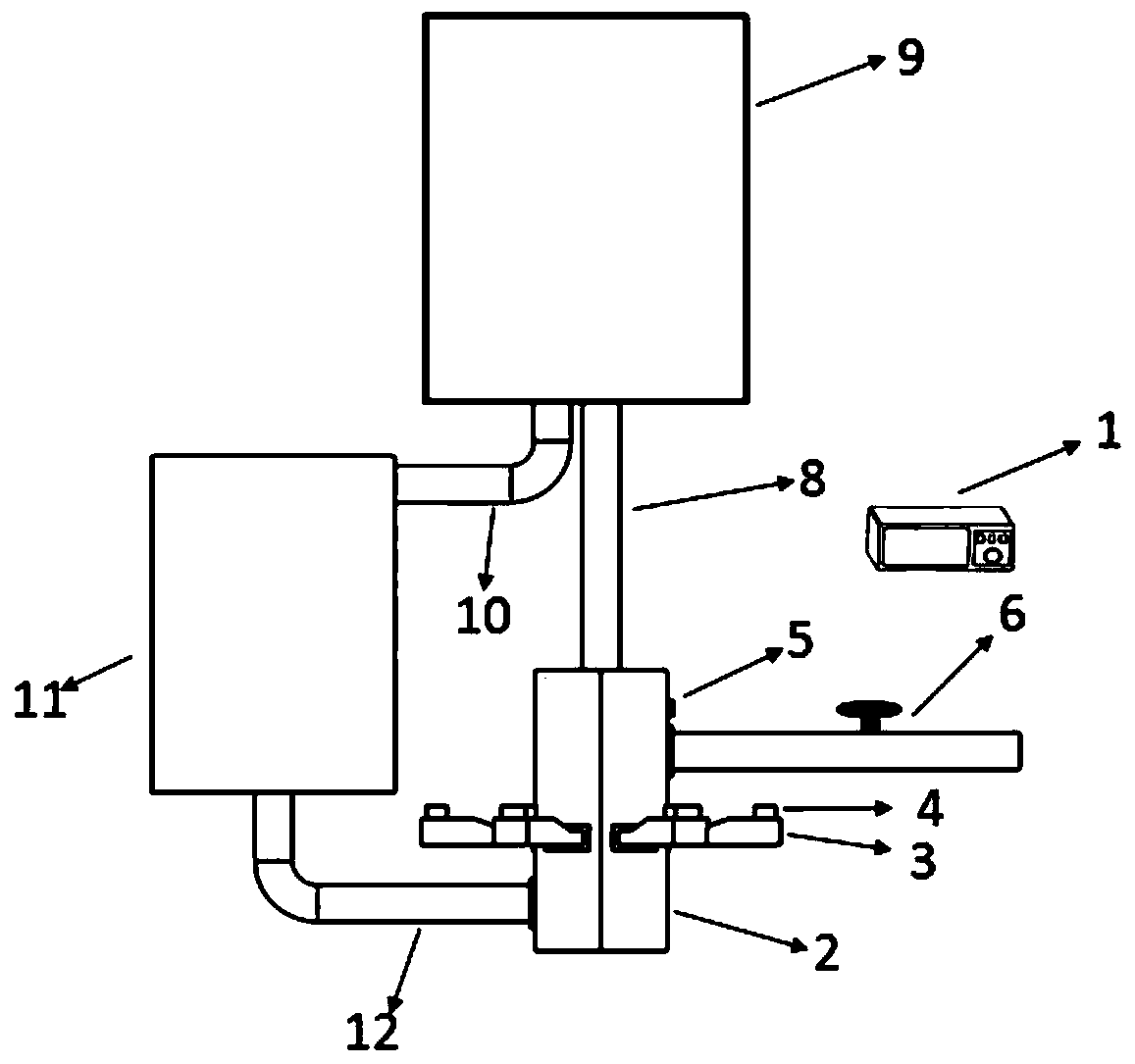

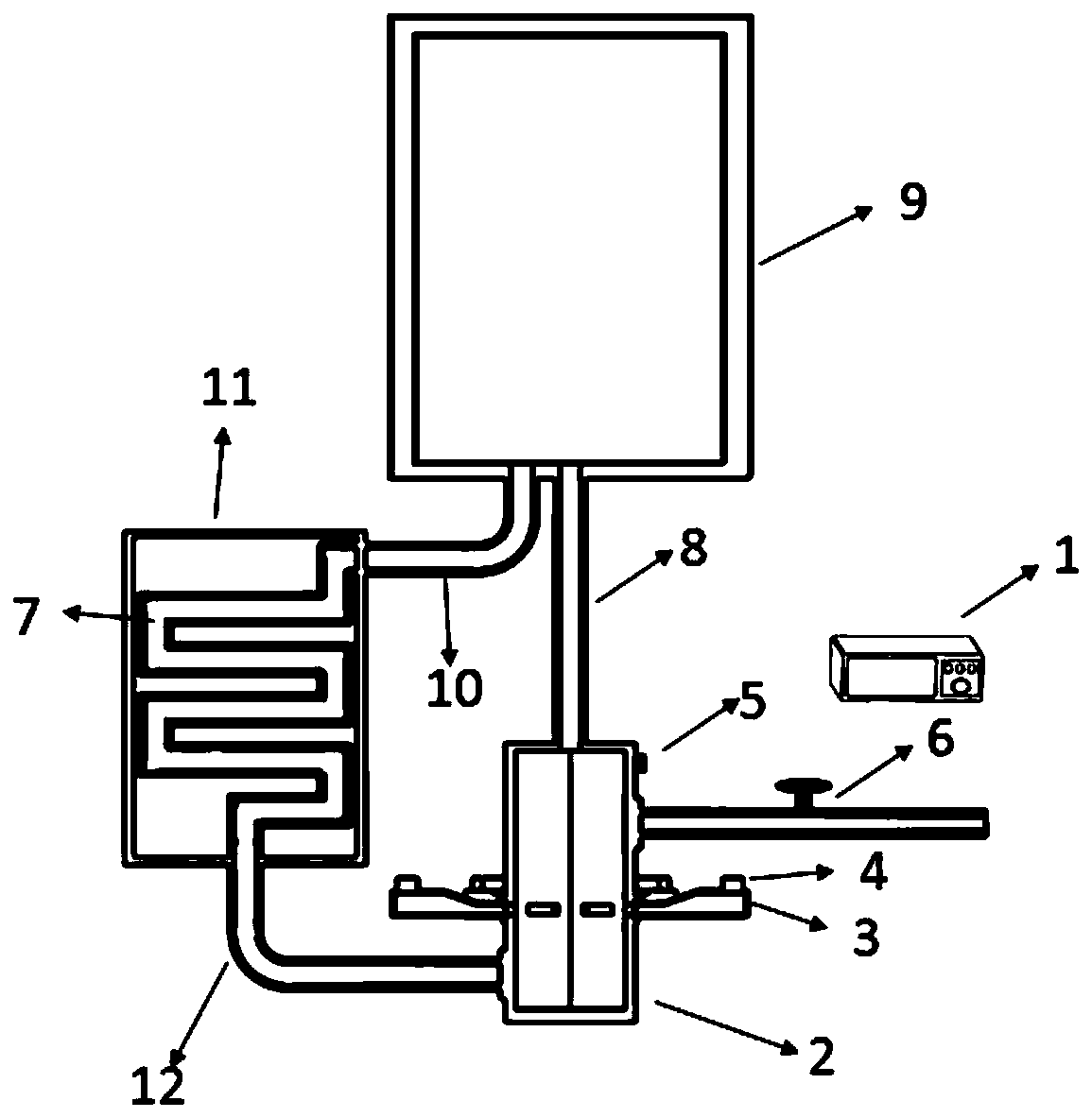

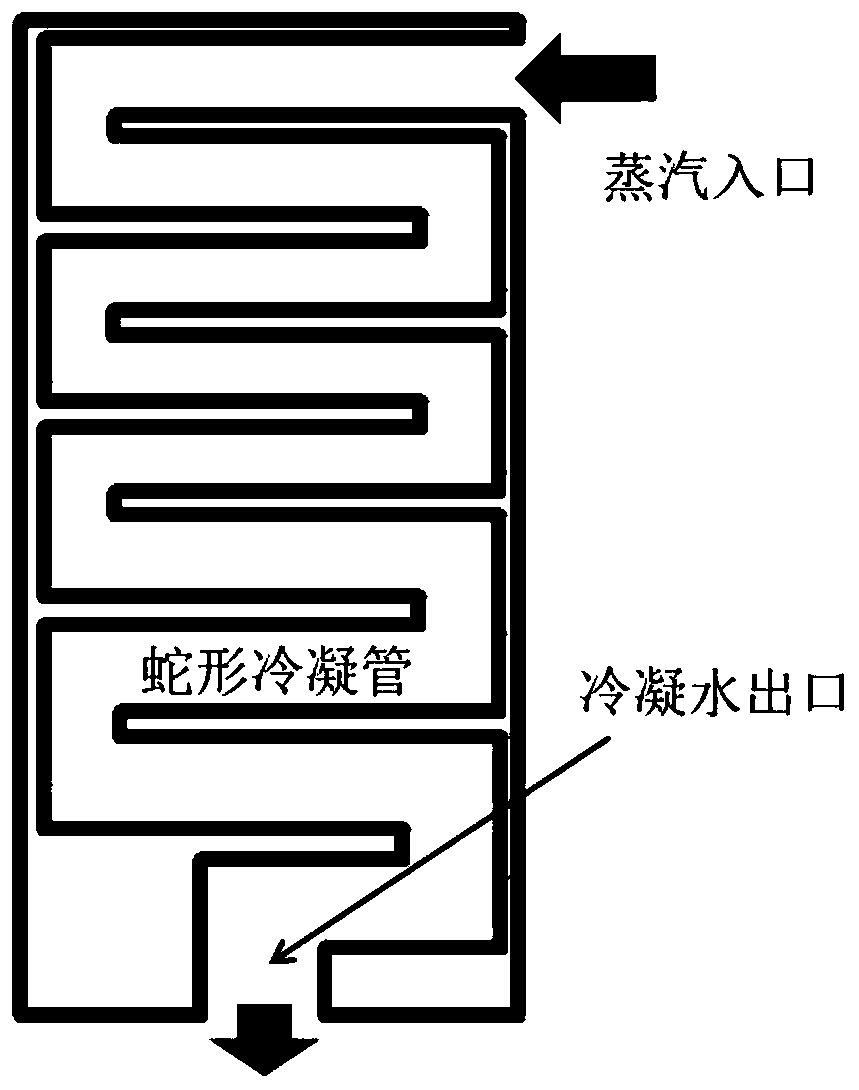

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] In this embodiment, microwave energy is used to quickly evaporate liquid water into water vapor, and the high-pressure water vapor enters the steam engine to generate power. At the same time, the condensing system can recover the used water vapor for reuse. Compared with traditional methods, such a device is not only safer, energy-saving, and easy to control, but also does not increase carbon emissions and is environmentally friendly.

[0023] The principle of this embodiment is to convert electromagnetic waves into heat energy, and heat liquid water to generate water vapor into mechanical energy. This device has higher efficiency, and has the advantages of controllability, safety, energy saving and environmental protection.

[0024] This embodiment is achieved through the following technical solutions, a microwave steam engine device, including...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap