Calibration method for relative position of linear laser three-dimensional measurement sensor and robot

A technology of three-dimensional measurement and calibration method, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem of unable to solve the problem of three-dimensional point cloud coordinate system and camera position calibration, difficult operation of sensor position calibration, and low calibration accuracy (error, etc. problems, to achieve the effect of convenient implementation, reduced complexity, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0030] The embodiment of the present invention proposes a method for calibrating the relative position of the line laser three-dimensional measurement sensor and the robot. In this method, the line laser three-dimensional measurement sensor scans different positions of the standard plane to obtain three-dimensional point cloud data, and the linear equation is fitted to calculate the direction vector of the line. The optimization problem under the constrained plane is used to solve the relative positional relationship between the line laser three-dimensional measurement sensor and the robot, so as to realize the fast and high-precision calibration of the line laser three-dimensional measurement sensor. The method specifically includes:

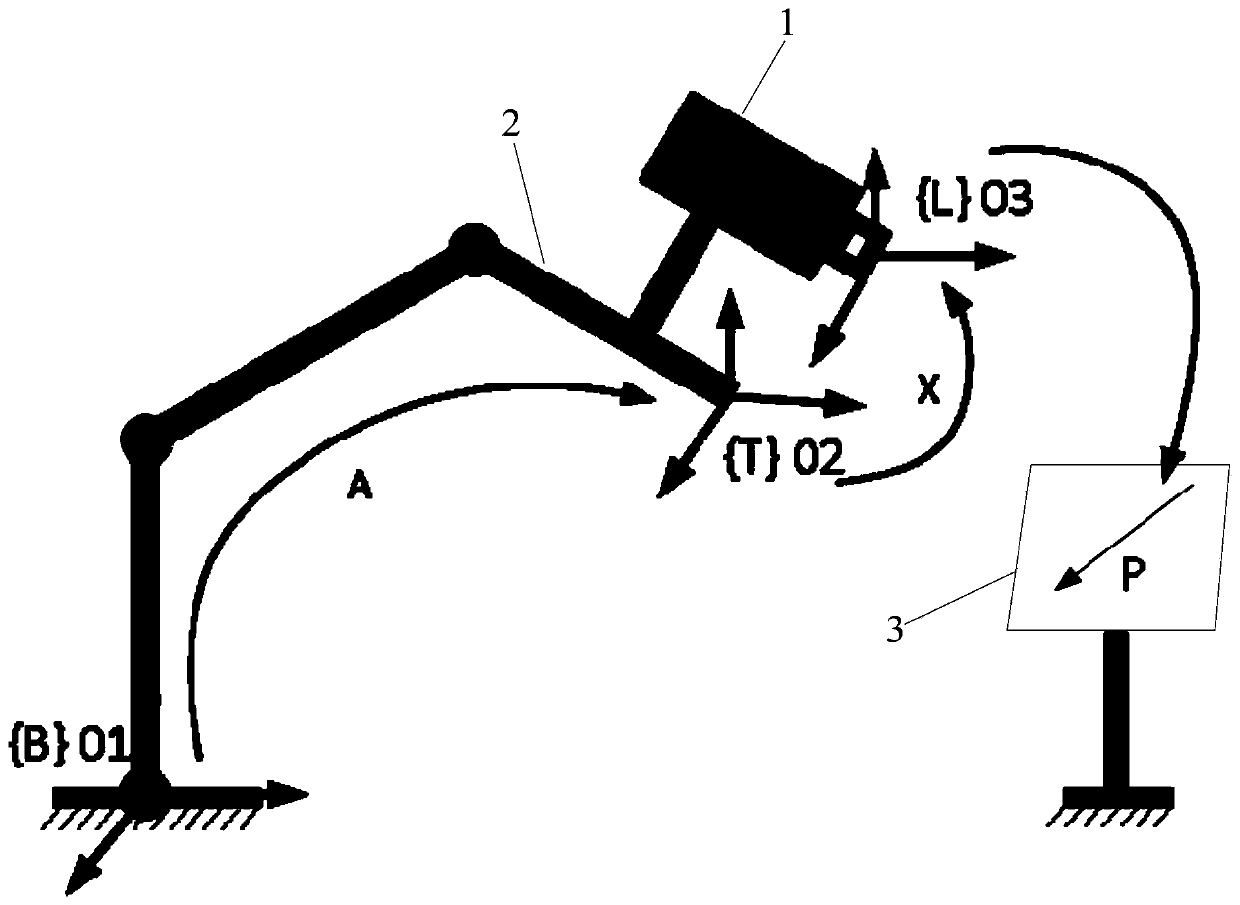

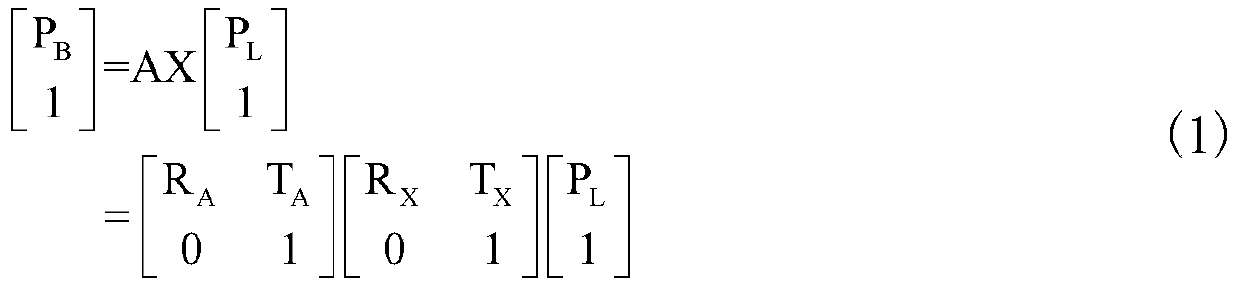

[0031] The line laser three-dimensional measurement sensor 1 is installed at the end of the robot arm 2; the robot base coordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com