Greenhouse assembling and building method

A technology for greenhouses and assembling equipment, which is used in greenhouse cultivation, botanical equipment and methods, horticulture, etc., can solve the problems of unqualified welding quality, reduce the production efficiency of steel skeletons, support the displacement of steel and skeletons, etc., and improve the qualification rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

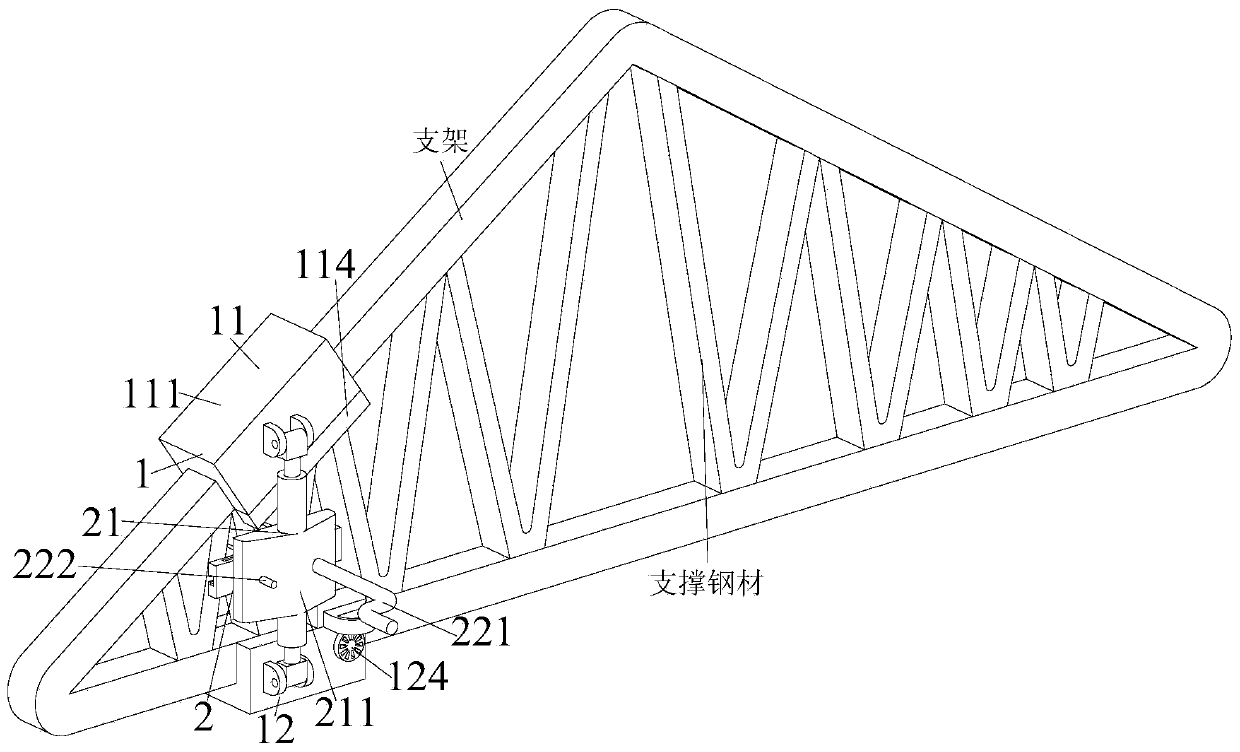

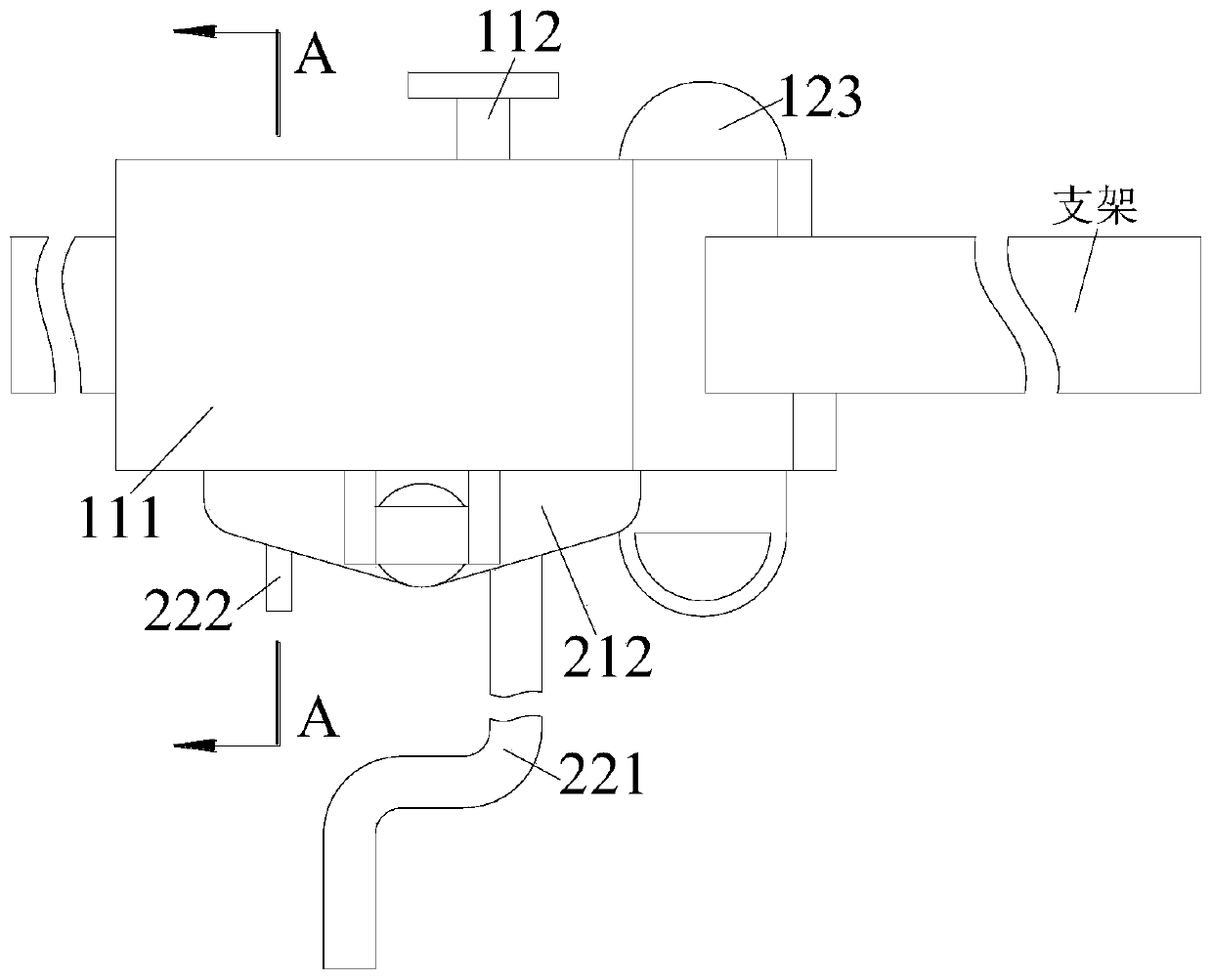

[0045] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 12 , to further elaborate the present invention.

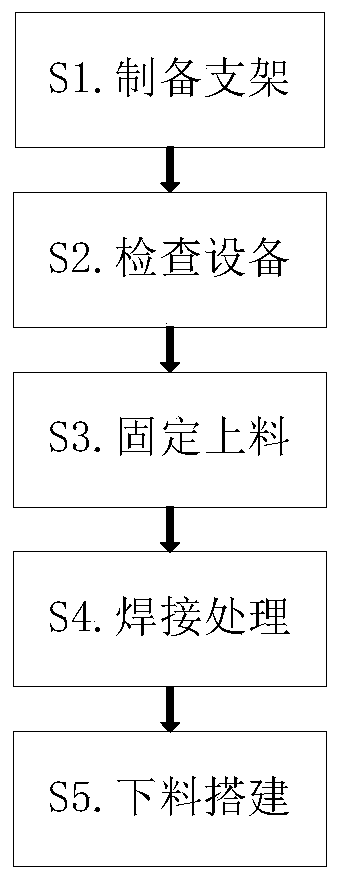

[0046] A greenhouse assembly method, the specific assembly method is as follows:

[0047] S1. Prepare the bracket: manually prepare the steel and weld the steel into a bracket;

[0048] S2. Inspection equipment: before using the greenhouse assembly equipment to assemble the greenhouse, inspect the greenhouse assembly equipment;

[0049] S3. Fixed loading: Manually install the greenhouse assembly equipment on the prepared support through the fixing device 1. After the greenhouse assembly equipment is installed, manually lock and fix the supporting steel on the clamping device 3, so that the adjustment device 2 Drive the supporting steel to be placed in the bracket;

[0050] S4. Welding treatment: After the supporting steel is placed in the bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com