High-precision bone saw

A high-precision, bone saw technology, applied in surgical saw, medical science, surgery, etc., can solve the problems of cutting error, increase the labor intensity of medical personnel, and the influence of human factors, and achieve convenient use, simple structure, and avoid errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

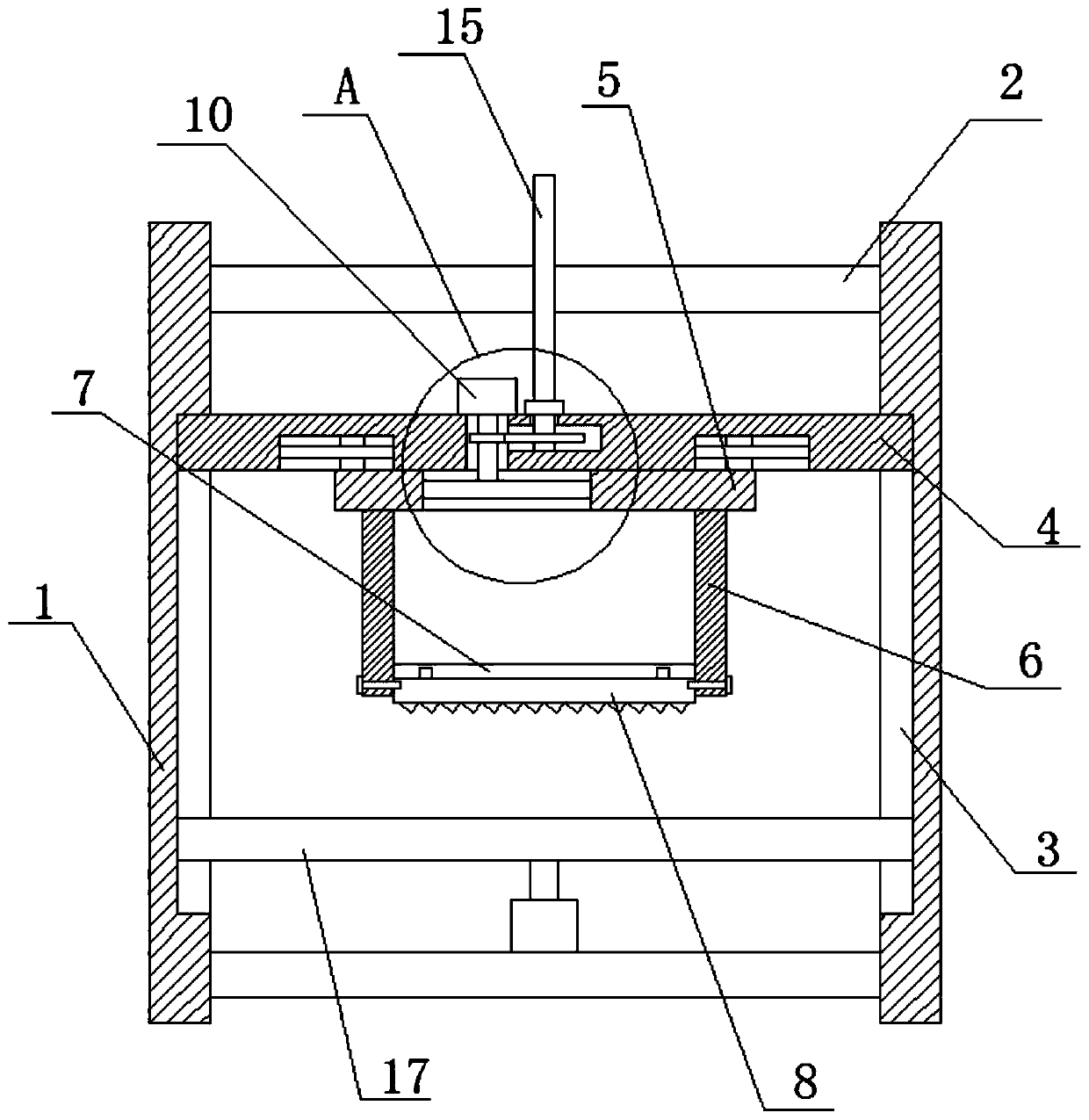

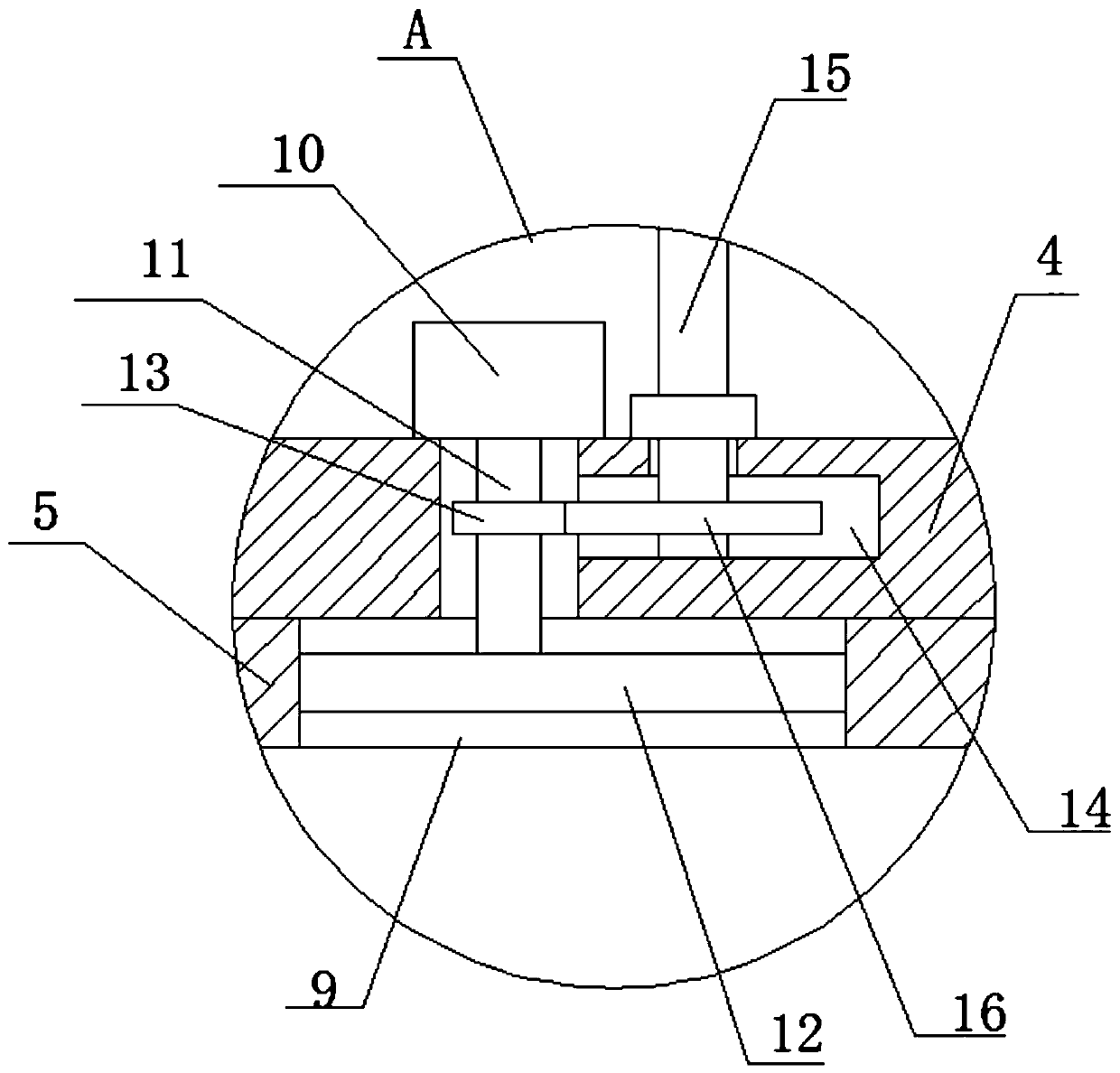

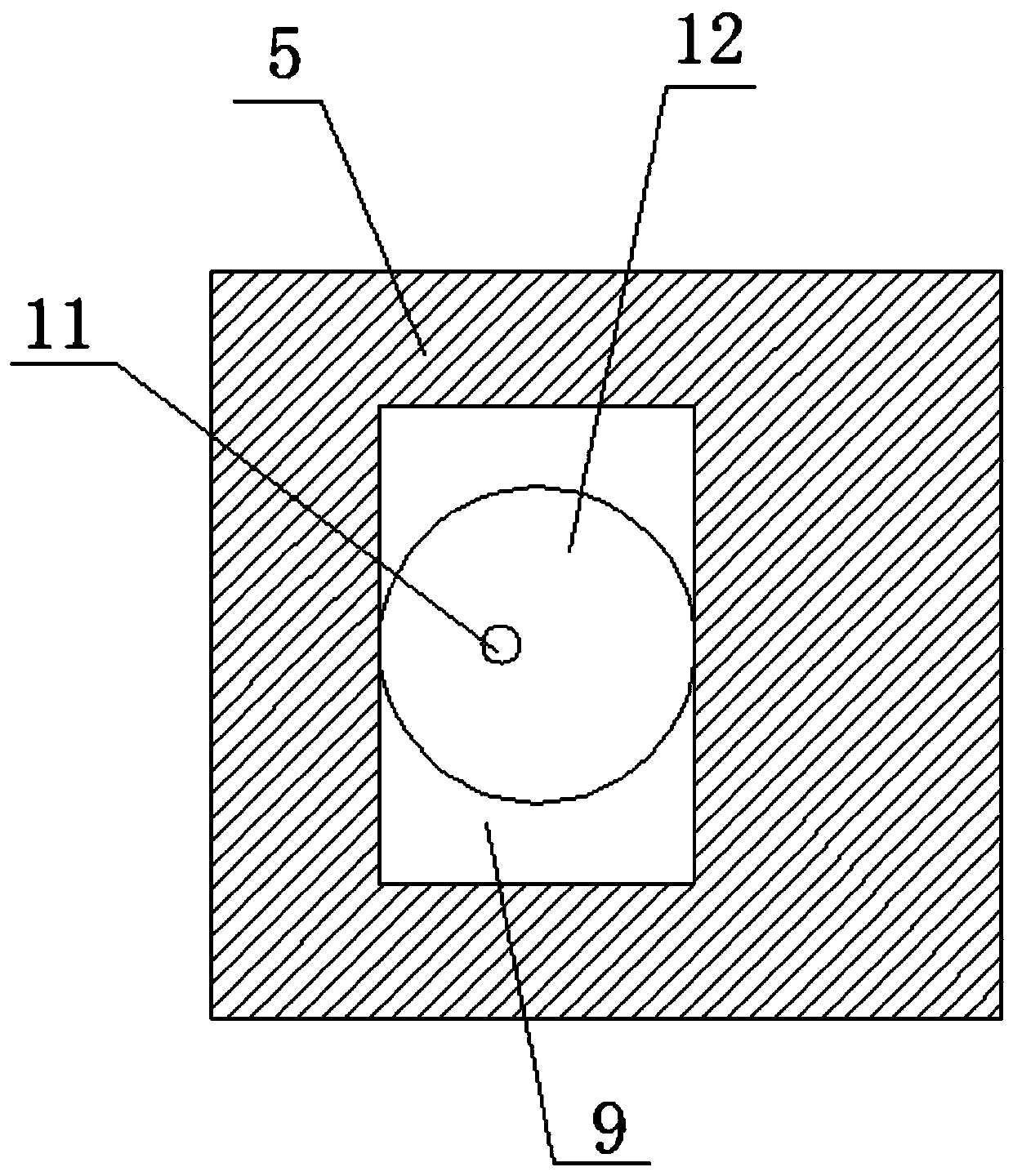

[0020] refer to Figure 1-3 , a high-precision bone saw, including two vertical boards 1, the sides of the two vertical boards 1 close to each other are provided with chute 3, and the two chute 3 are slidingly installed with a placement plate 17 and a pressure plate 4, the pressure plate 4 The bottom of the horizontal moving plate 5 is slidably installed with two vertical mounting plates 6 fixedly mounted on the bottom of the horizontal moving plate 5, and the side of the two vertical mounting plates 6 close to each other is fixedly mounted with the same bearing plate 7, the bearing plate The bottom of 7 is equipped with saw 8, offers vertical hole 9 on the horizontal moving plate 5, and the top of pressing plate 4 is fixedly installed with motor 10, and the output shaft of motor 10 is fixedly installed with an end of vertical bar 11, and the other end of vertical bar 11 An eccentric wheel 12 is fixedly installed, the outer side of the eccentric wheel 12 is in contact with the...

Embodiment 2

[0026] refer to Figure 1-3 , a high-precision bone saw, including two vertical boards 1, the sides of the two vertical boards 1 close to each other are provided with chute 3, and the two chute 3 are slidingly installed with a placement plate 17 and a pressure plate 4, the pressure plate 4 The bottom of the horizontal moving plate 5 is slidingly installed with a horizontal moving plate 5, and the bottom of the horizontal moving plate 5 is fixedly installed with two vertical mounting plates 6 by welding, and the side of the two vertical mounting plates 6 close to each other is fixedly installed with the same bearing plate by welding 7. A saw 8 is installed on the bottom of the bearing plate 7, a vertical hole 9 is provided on the horizontal moving plate 5, a motor 10 is fixedly installed on the top of the pressure plate 4 by welding, and a vertical rod 11 is fixedly installed on the output shaft of the motor 10 by welding. One end, the other end of the vertical rod 11 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com