Treatment device for manufacturing municipal garbage regenerated insulation bricks

A technology of municipal waste and treatment device, which is applied in the field of municipal waste recycling and thermal insulation brick making treatment device, can solve the problems of poor crushing effect of municipal waste, can not meet the needs of municipal waste crushing, etc., and achieve the effect of improving the crushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

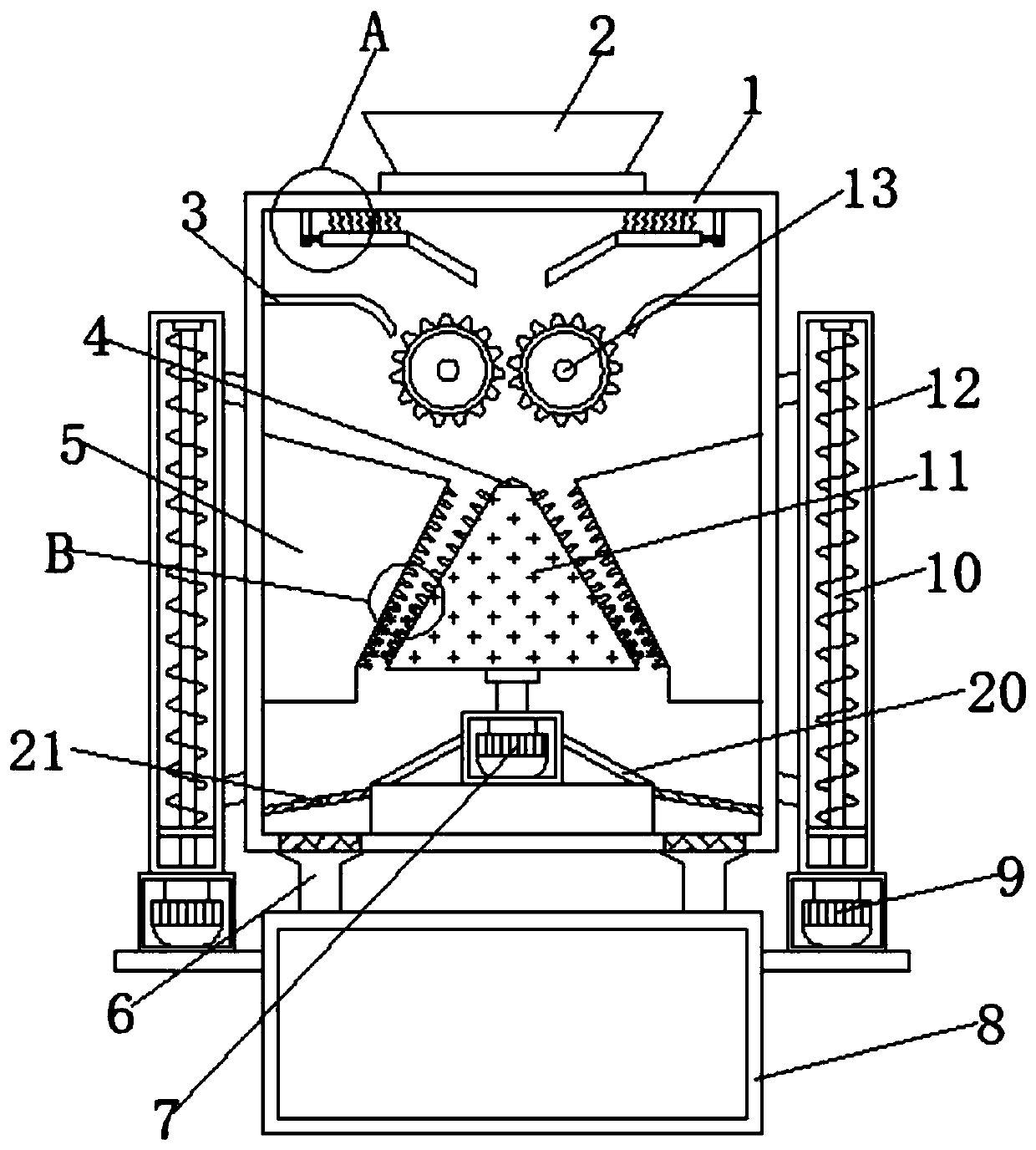

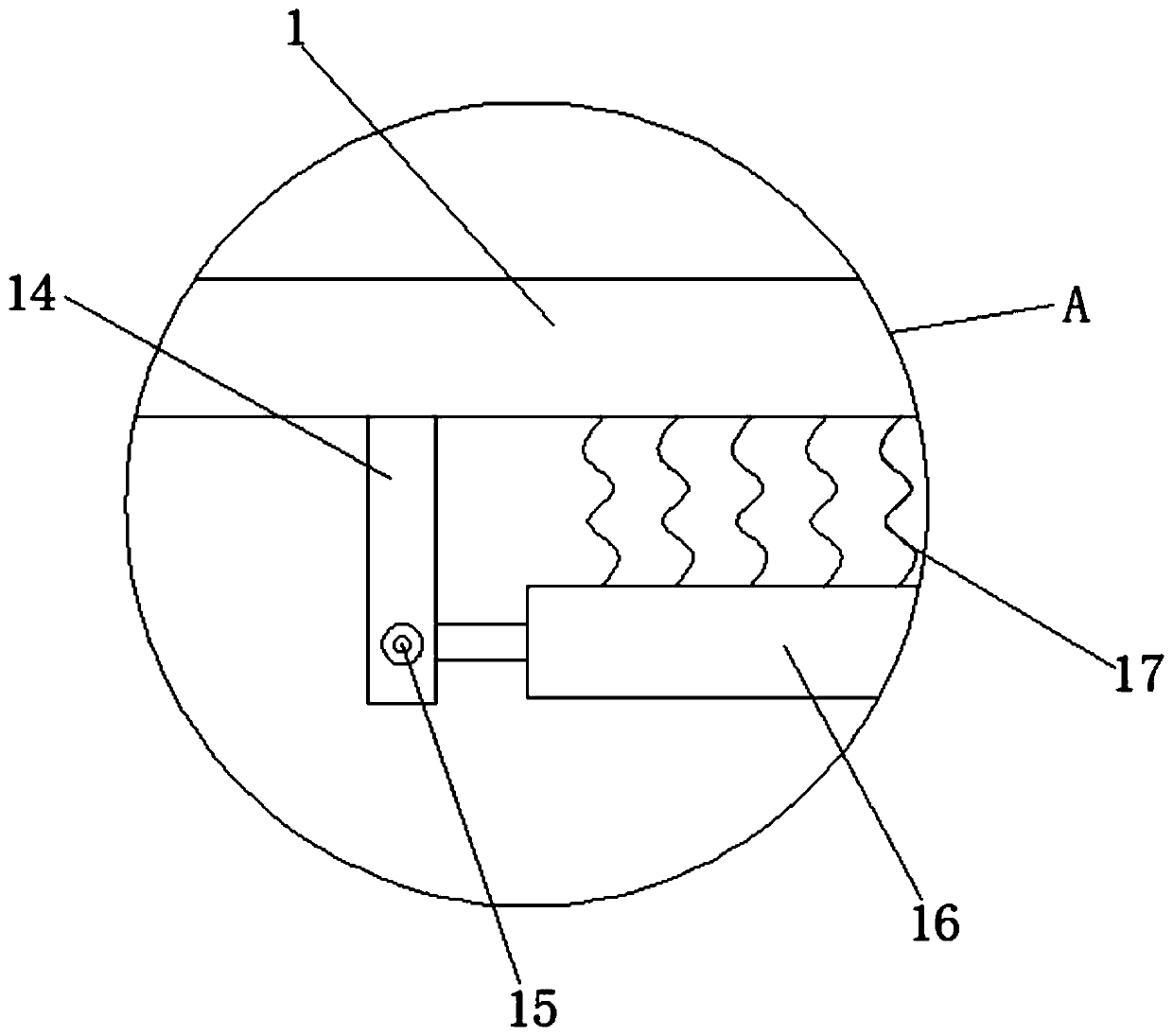

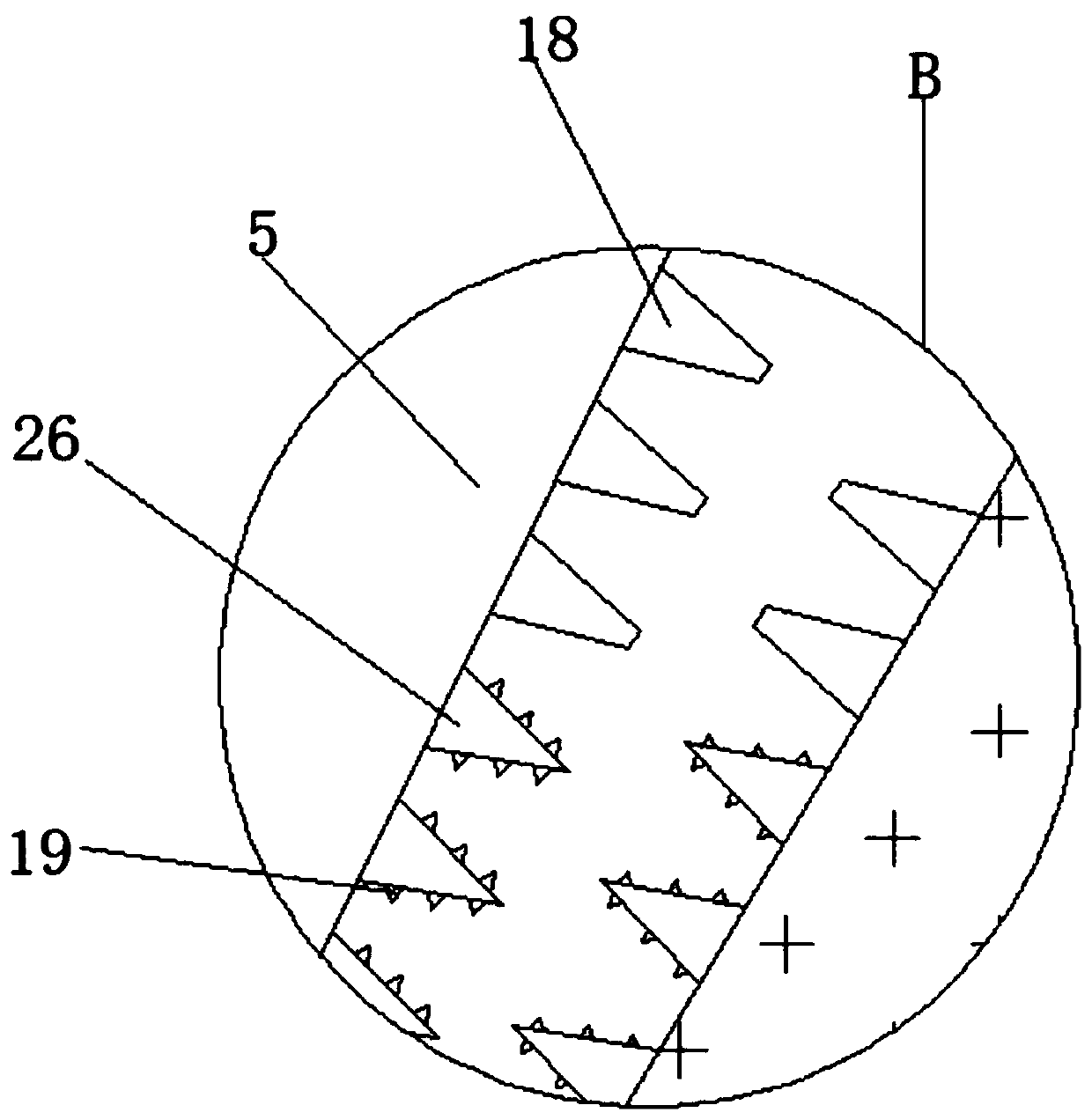

[0032] refer to Figure 1-4 , a processing device for making municipal garbage recycled heat preservation bricks, comprising a box body 1, a top outer wall of the box body 1 is provided with a feed inlet, and the inner wall of the feed inlet is welded with a feed hopper 2, and the inner wall of the box body 1 is provided with Pulverizing roller 13, and the number of pulverizing roller 13 is two, and two pulverizing rollers 13 are engaged with each other, and the inner wall of both sides of box body 1 is all connected with fixed block 5 by bolt, and the bottom inner wall of box body 1 is connected with base by bolt, And the top outer wall of the base is connected with the first protective shell by bolts, the bottom inner wall of the first protective shell is connected with the first motor 7 by bolts, and one end of the output shaft of the first motor 7 is connected with a connecting block 11 by bolts, and the connecting block 11 The cross-section is trapezoidal, and the angle b...

Embodiment 2

[0036] refer to Figure 5 , a processing device for the production of municipal waste regeneration insulation bricks. Compared with Embodiment 1, the outer wall of the bottom of the fixed block 5 is connected with a third protective shell by bolts, and the inner wall of one side of the third protective shell is connected by bolts. The third motor 25, one end of the output shaft of the third motor 25 is connected with a rotating rod 24 by a bolt, and the outer walls of both sides of the rotating rod 24 are connected with a stirring rod 23 by a bolt.

[0037] Working principle: When people crush the municipal waste, they can put the municipal waste into the box body 1 through the hopper 2, and the buffer plate 16 can prevent the municipal waste from directly falling on the outer wall of the crushing roller 13, causing damage to the device , play a good buffering effect, and the baffles 3 provided on the inner walls of the two sides of the box body 1 can prevent municipal waste f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com