Multilayer sealed vibrating screen with screen cloth convenient to replace

A multi-layer sealed and easy-to-replace technology, which is applied in the fields of filters, chemical instruments and methods, cleaning methods and utensils, can solve problems such as low efficiency, troublesome replacement, and affecting production efficiency, so as to improve work efficiency and reduce labor costs. Intensity, novelty effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

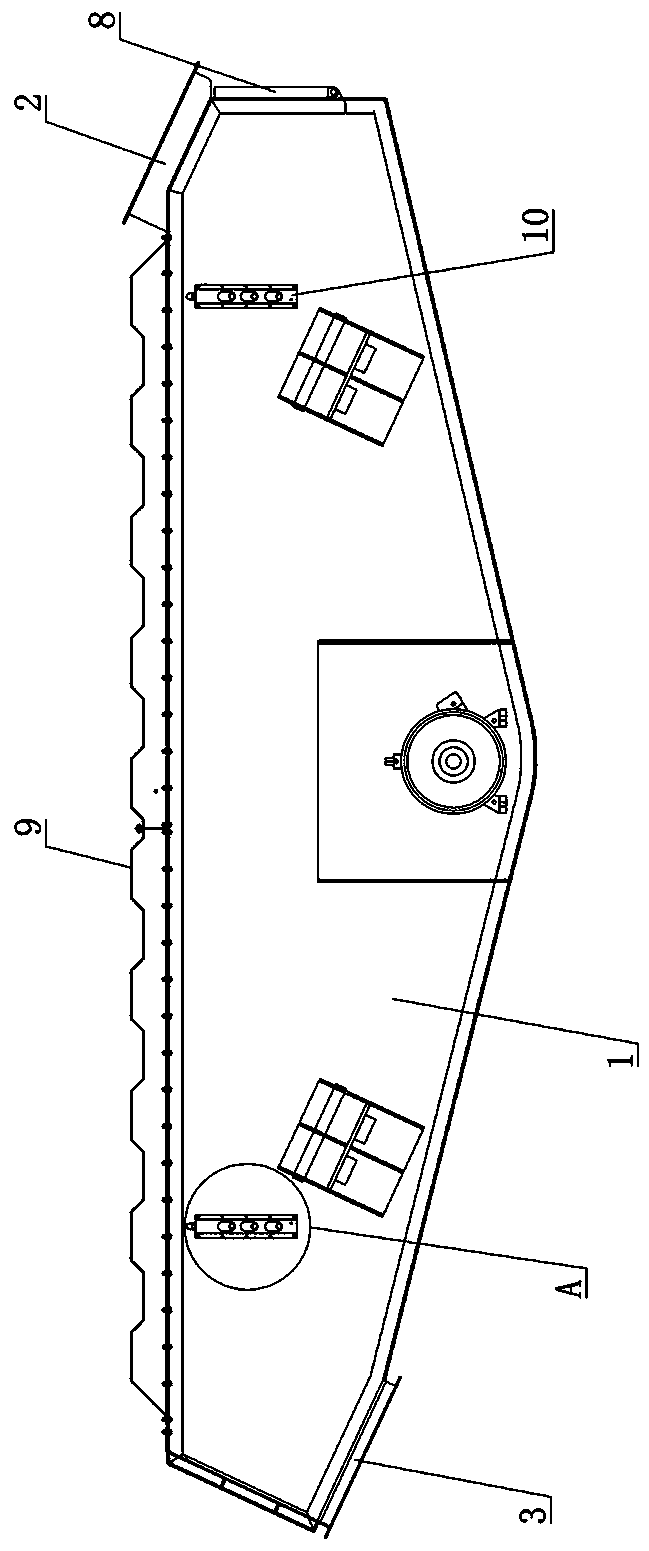

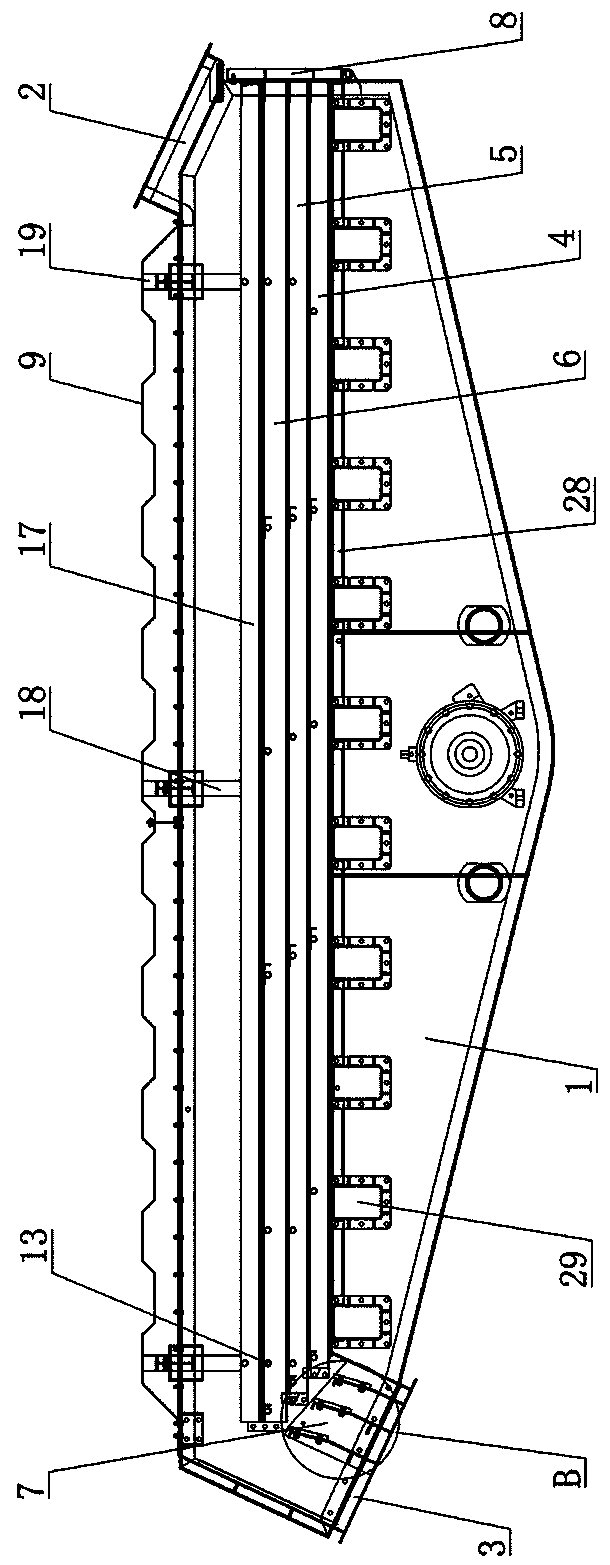

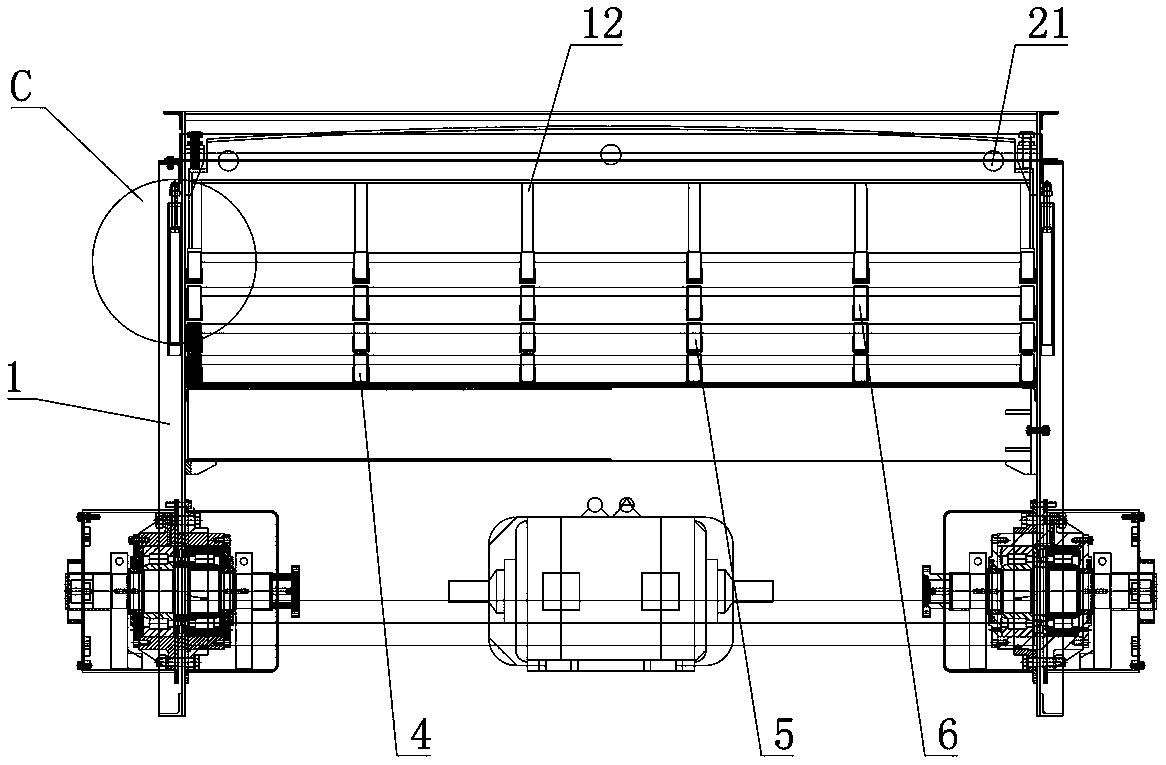

[0019] Depend on Figure 1 to Figure 9 Given, the present invention includes a sieve body 1, the right end and the left end of the sieve body 1 are respectively provided with an upwardly opening feed port 2 and a downwardly opening discharge port 3, and the inner cavity of the sieve body 1 is sequentially stacked from bottom to top. There are the first screen bracket 4, the second screen bracket 5 and the third screen bracket 6, the first screen bracket 4, the second screen bracket 5 and the third screen bracket 6 are all A sieve is provided, and a material-receiving combination 7 cooperating with the first sieve-mesh bracket 4, the second sieve-mesh bracket 5 and the third sieve-mesh bracket 6 is also provided in the discharge port 3, and the material-receiving combination 7 will The material flowing out to the discharge port 3 through the first screen bracket 4, the second screen bracket 5 and the third screen bracket 6 is stratified, and the upper end of the third screen br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com