Portable iron sheet cutting machine based on metal machining

A metal processing and portable technology, applied in metal processing equipment, metal sawing equipment, manufacturing tools, etc., can solve the problems of easy injury of workers, low work efficiency, and blade leakage outside, so as to increase the convenience of cutting and enhance Cutting effect, effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

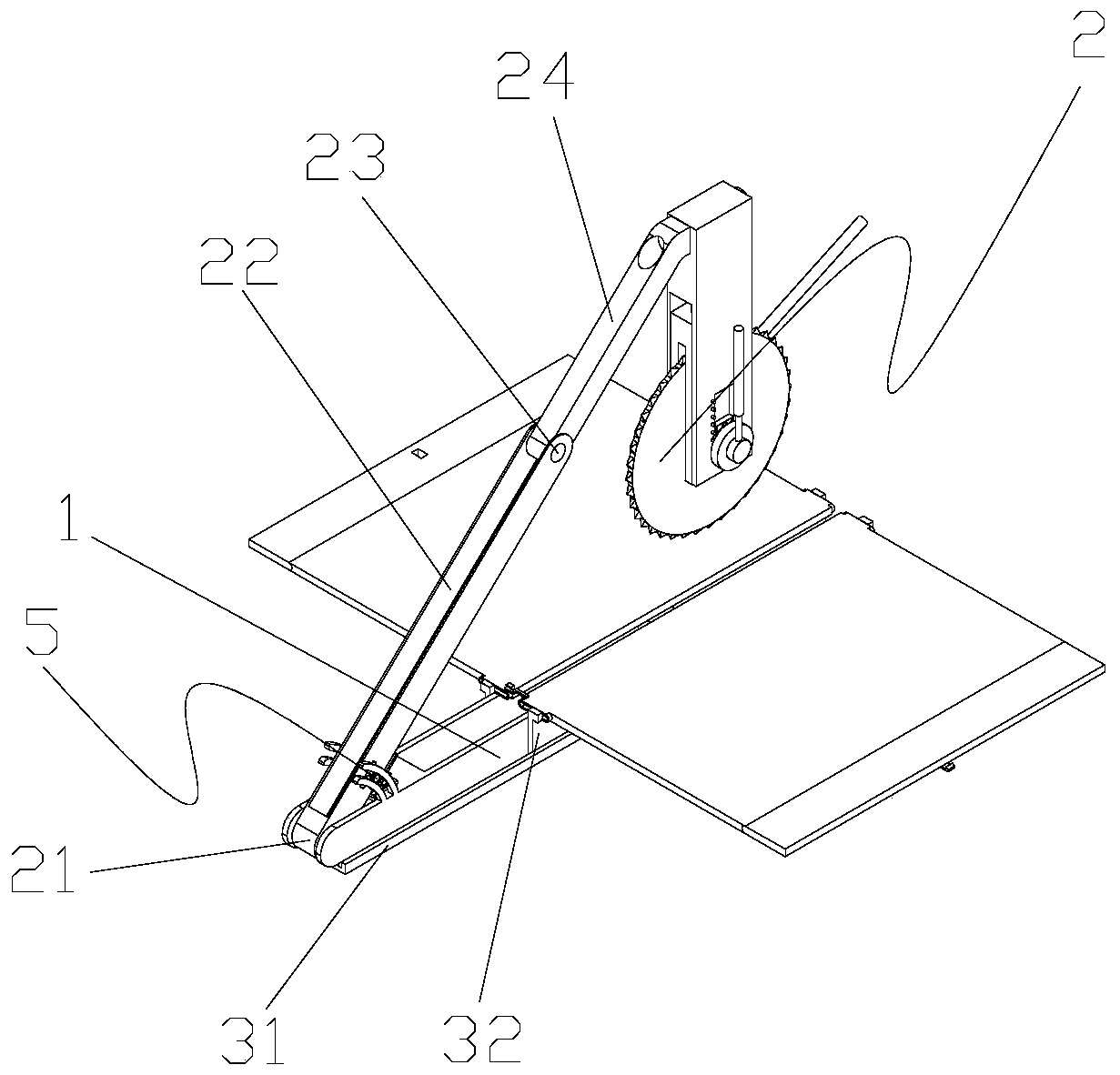

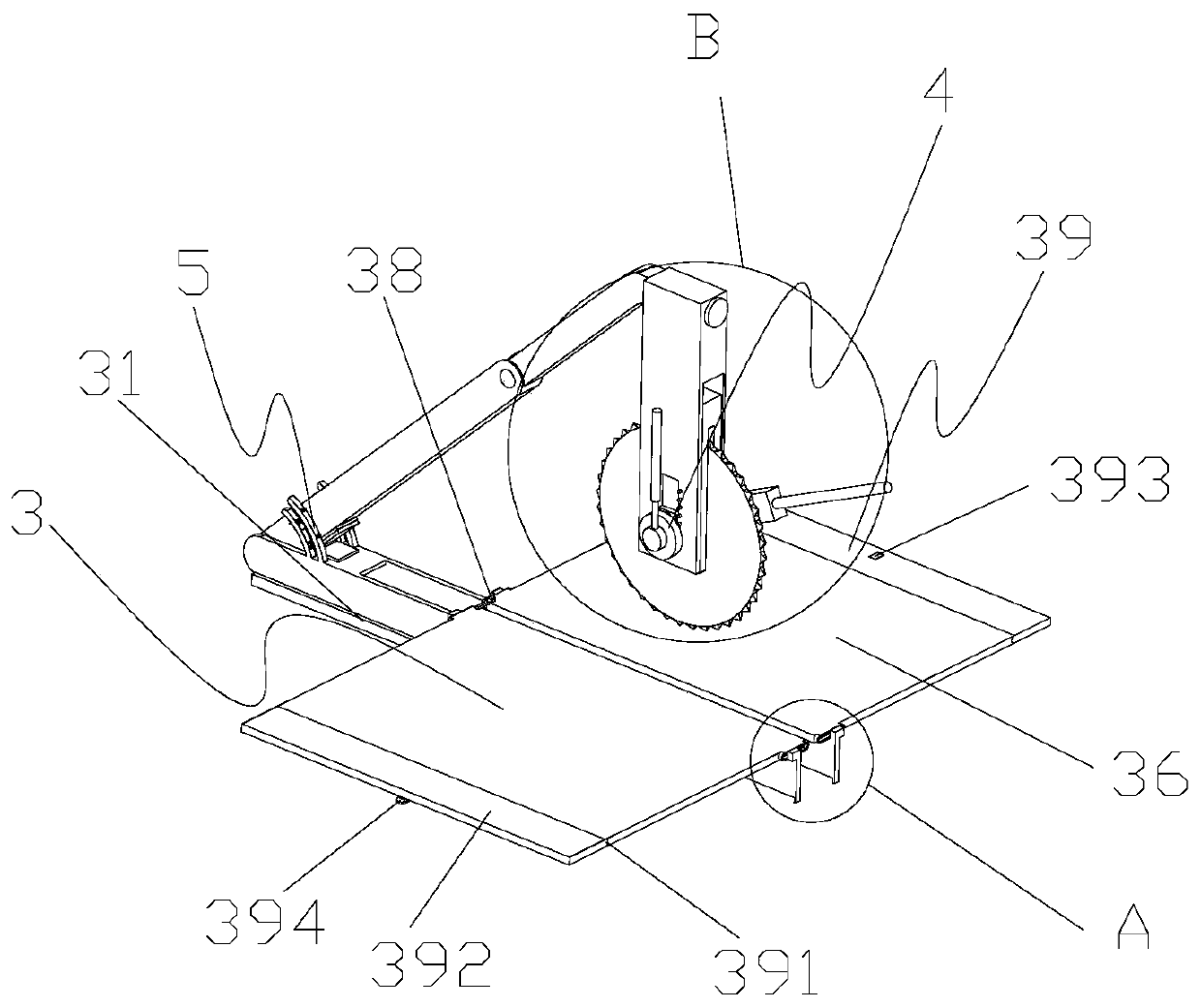

[0034] Such as Figure 1-19 As shown, a portable iron sheet cutting machine based on metal processing includes a base 1 and a cutting device 2; the cutting device 2 is arranged on the base; A connecting arm 22 is arranged on the first rotating member, a second rotating member 23 is arranged on the first connecting arm, a second connecting arm 24 is arranged on the second rotating member, and the turning part 3 is arranged on the On the base, the cutting assembly 4 is arranged on the second connecting arm, and the fixing part 5 is arranged on the base; both the base and the first connecting arm are hollow structures; the second connecting arm can be wound around The second rotating part is snapped into the first connecting arm; the first connecting arm can be snapped into the base around the first rotating part; both the first rotating part and the second rotating part are hinged.

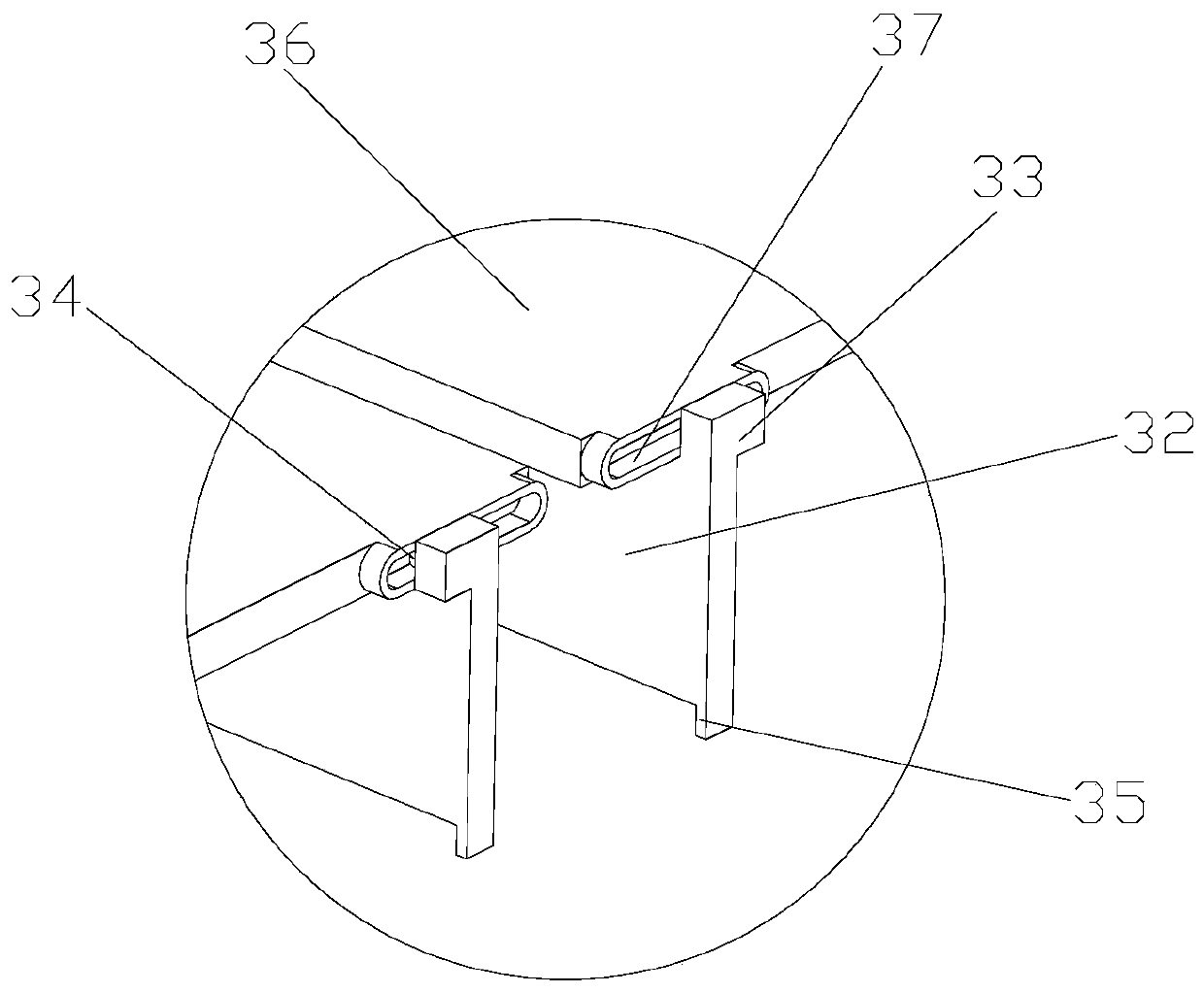

[0035] Such as Figure 1-3 As shown, the folding part 3 includes a first sliding rail 31, a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com