Safe and efficient civil defense door alloy structure

A high-efficiency technology for air defense doors, applied in door leaves, door/window accessories, and anti-war damage, it can solve problems such as easy collision with people, poor sealing effect, and potential safety hazards, so as to avoid potential safety hazards and ensure the sealing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

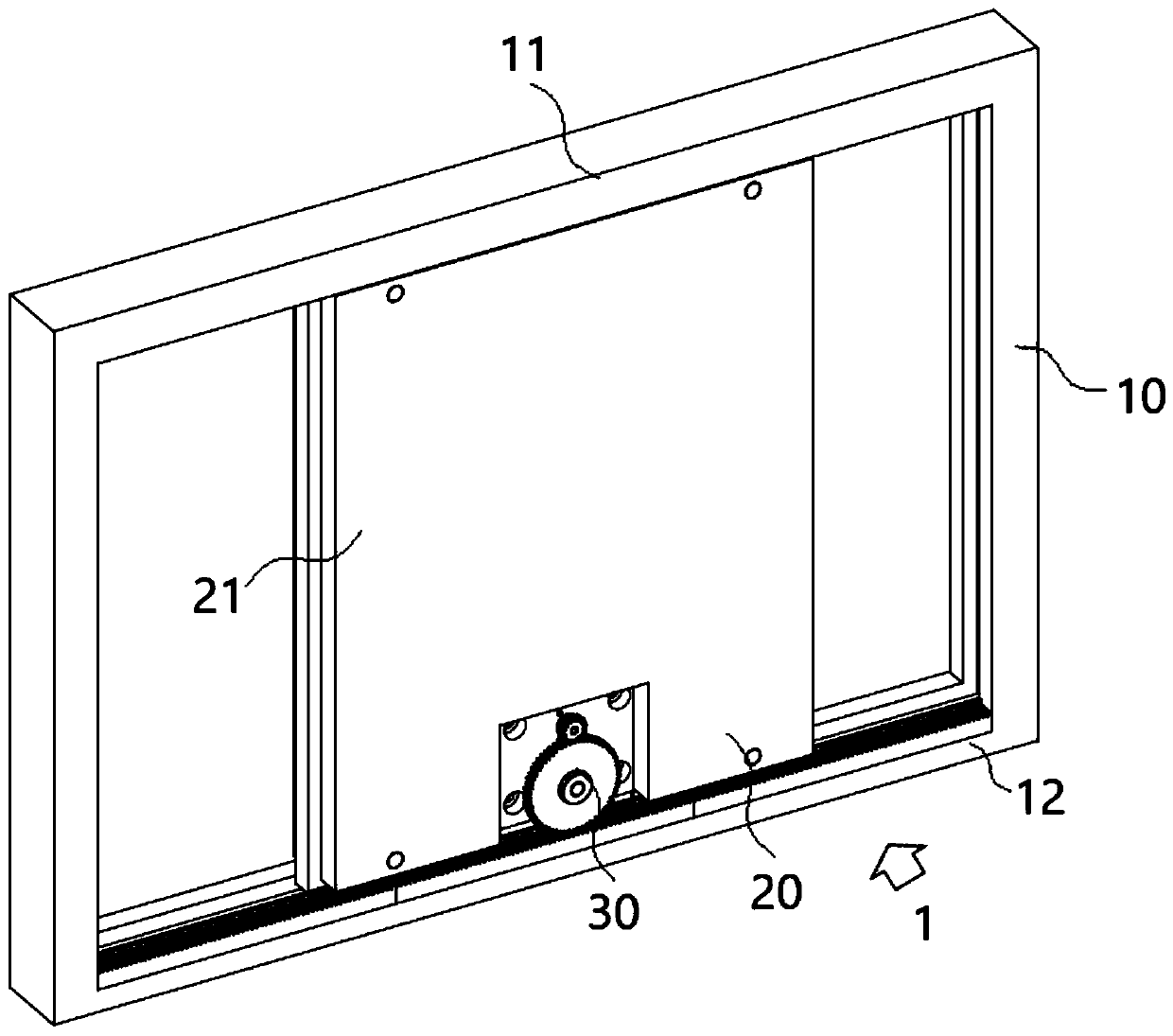

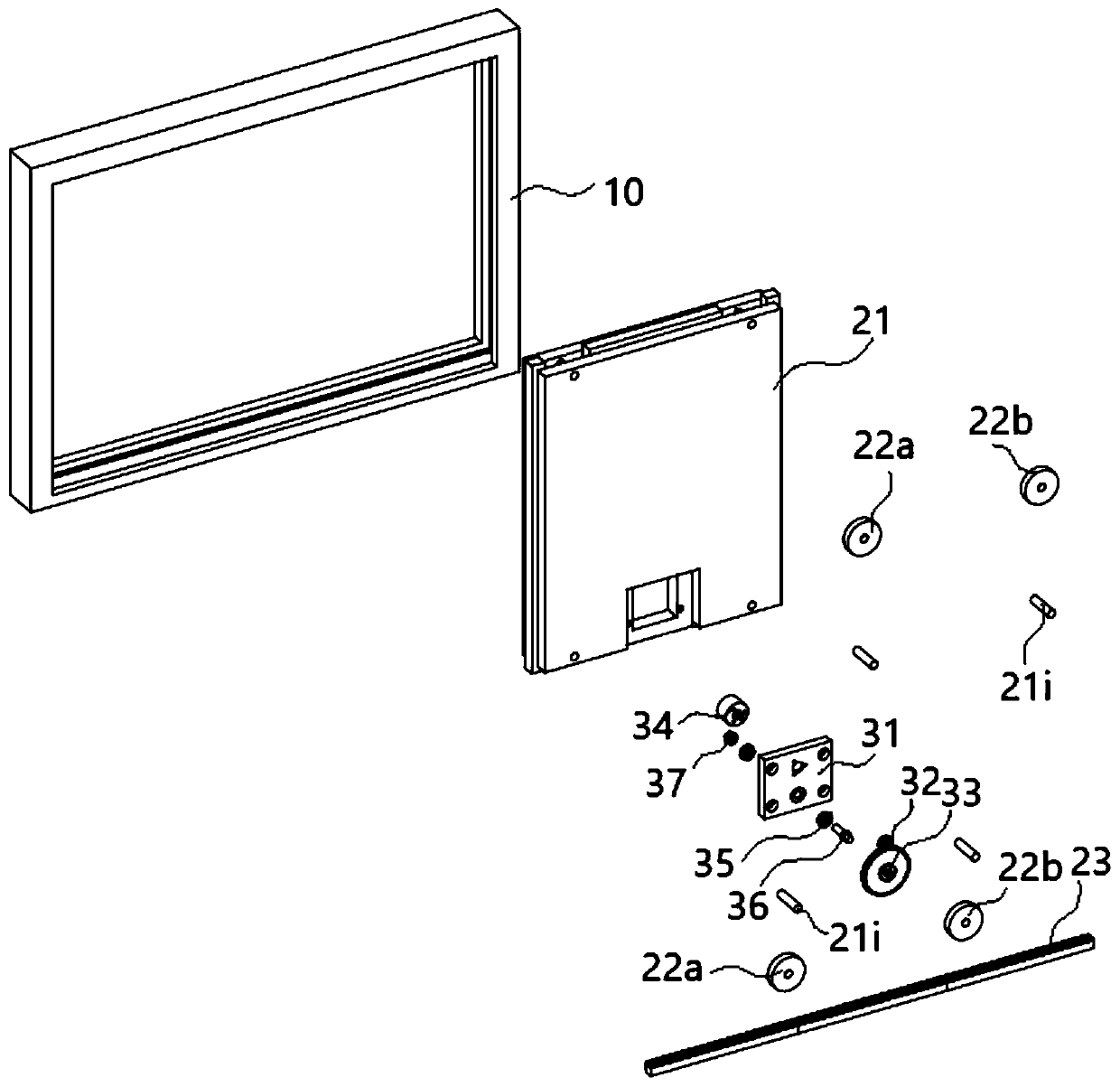

[0058] Example 1: see figure 1 and figure 2 A safe and efficient civil air defense door alloy structure 1 shown includes a door frame 10 fixedly installed on the wall, the opening of the door frame 10 is closed by the wall, and the opening on the other side is selectively opened and closed by the civil air defense door alloy plate 20 The upper frame 11 and the lower frame 12 of the door frame 10 are respectively provided with slide rails 13, and the civil air defense door alloy plate 20 can be relatively slidably installed in the slide rail 13 to realize selective opening and closing. The civil air defense door alloy plate 20 includes civil air defense door alloy Plate body 21, the upper end and the lower end of the civil air defense door alloy plate body 21 are respectively slidably installed in the slide rail 13 corresponding to it by rollers, and the bottom of the civil air defense door alloy plate body 21 is provided with a slide drive assembly 30, wherein the slide drive...

Embodiment 2

[0062] Embodiment 2: the present embodiment proposes a kind of high-strength alloy for civil air defense door, as the alloy plate body 21 of civil air defense door in embodiment 1, adopts alloy steel plate as raw material steel plate, and this alloy steel plate comprises following composition:

[0063] 1-2.5wt% aluminum;

[0064] 0.08-0.15 wt% carbon;

[0065] 1-2 wt% manganese;

[0066] 0.08-0.2 wt% titanium;

[0067] 0.2-0.6 wt% chromium;

[0068] balance iron;

[0069] Carry out nitriding treatment process on the alloy steel plate to form a durable nitriding protective layer on the surface of the alloy steel plate;

[0070] Preferably, in this embodiment, the thickness range of the durable nitriding protective layer is 10-30 microns, and the thickness of the alloy steel plate is 1-5 mm;

[0071] Preferably, in this embodiment, the nitriding treatment process adopts a gas nitriding process, please refer to Figure 5 As shown, the gas nitriding process includes the foll...

Embodiment 3

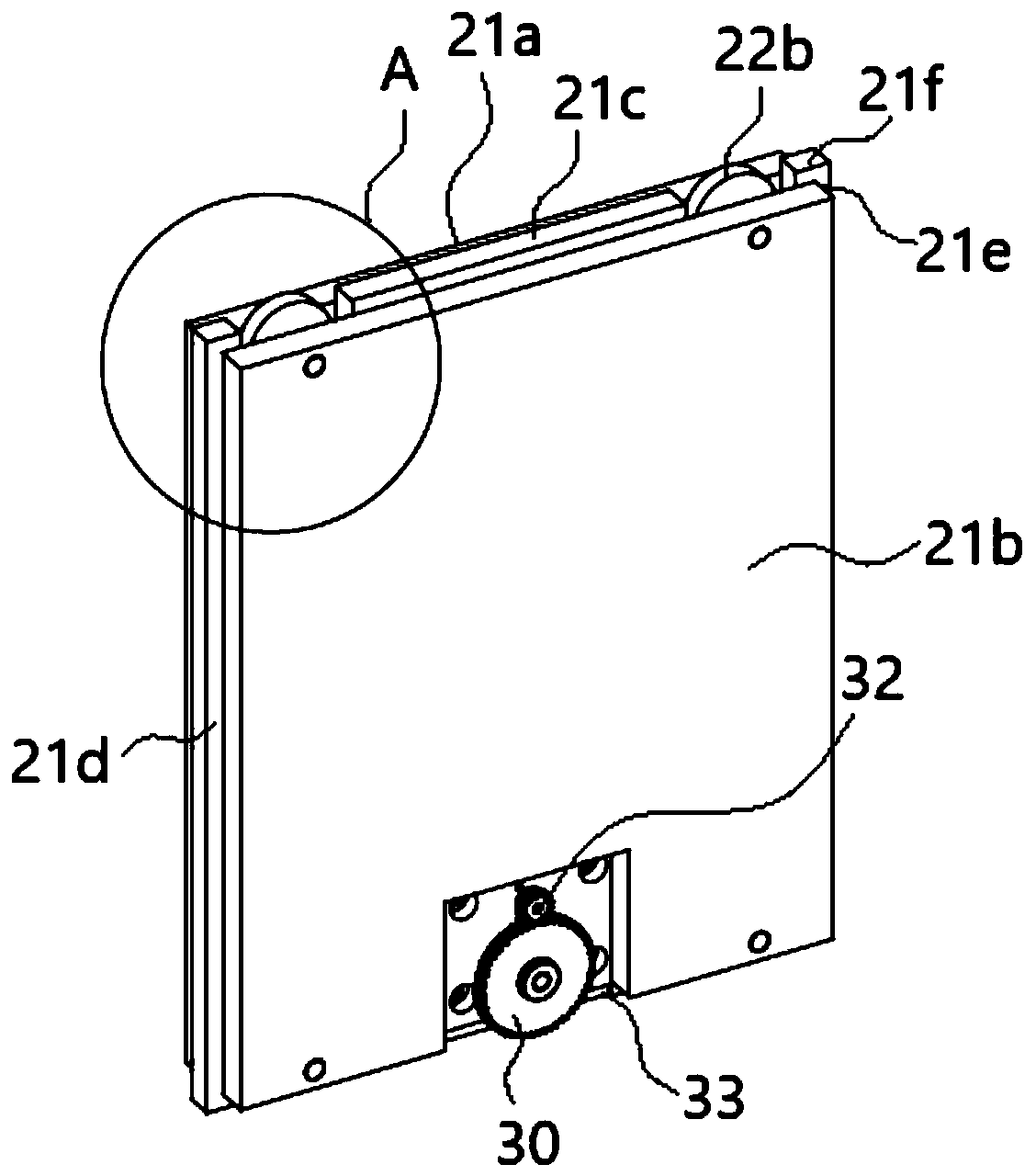

[0079] Example 3: Please see further image 3 and Figure 4 shown, combined with figure 1 and figure 2 As shown, the present embodiment proposes a processing method of a high-strength alloy for civil air defense doors. The high-strength alloy is used as the civil air defense door alloy plate body 21 in Embodiment 1, and the civil air defense door alloy plate body 21 includes a space and is flush. Shaped first alloy plate 21a and second alloy plate 21b, the first alloy plate 21a and the second alloy plate 21b are integrally press-fitted with the central core layer alloy insert 21c located in the middle of the interval space through the cold assembly process. The process is integrated to press-fit the left end surface core alloy insert 21d and the right end surface core alloy insert 21e located on both sides of the interval space, wherein the middle core alloy insert 21c is respectively connected to the left end core alloy insert 21d and the right end surface The core layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com