Calculation method of pressure behind stopper mouth considering water injection start pressure gradient

A technology of starting pressure gradient and calculation method, which is applied in the fields of instrumentation, earthwork drilling, design optimization/simulation, etc., can solve the problem that the oil reservoir cannot realize fine layered injection, etc., so as to improve the development effect and increase the longitudinal production of the reservoir. degree, the effect of increasing the degree of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

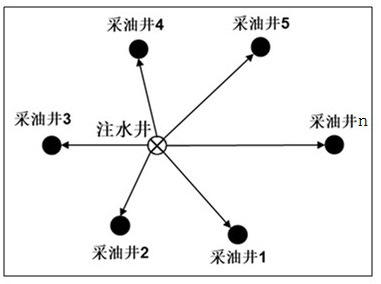

[0105] (1) A typical injection-production well group in a block of Daqing Oilfield was selected as the research object. The well group contained 1 water injection well and 4 oil production wells, and the water injection well group was divided into 7 injection-production intervals. See the attached figure 2 . The basic parameters of water injection wells and production wells in typical injection well groups are shown in Table 1.

[0106] Table 1 Basic parameters of typical injection-production well groups

[0107]

[0108] (2) Calculate the proration pressure difference of the water injection well in each injection-production section.

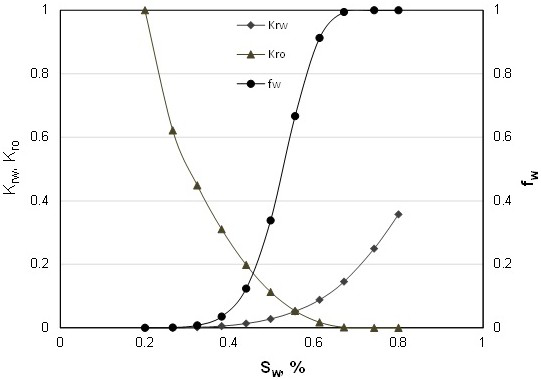

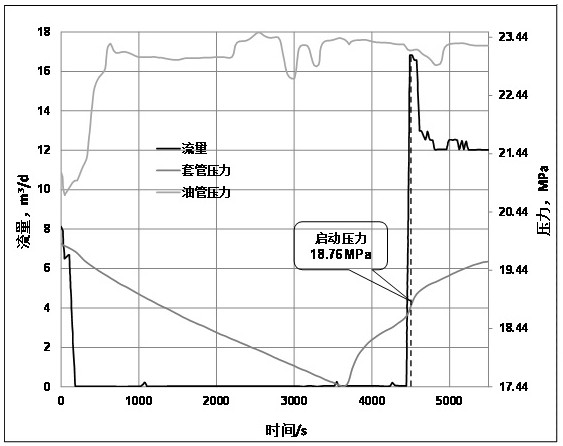

[0109] Specifically, the total injection volume designed for water injection wells is 100m 3 Based on / d, the equivalent well spacing between water injection wells and production wells, the average water content at the production end of the production wells in the well group, the relative permeability of the water phase in the injection-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com