A batch verification equipment for platinum-rhodium thermocouple processing

A thermocouple and platinum-rhodium technology, which is applied in the field of batch verification equipment for platinum-rhodium thermocouple processing, can solve the problems of manpower consumption and low efficiency, and achieve the effects of convenient loading and unloading, high detection accuracy and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

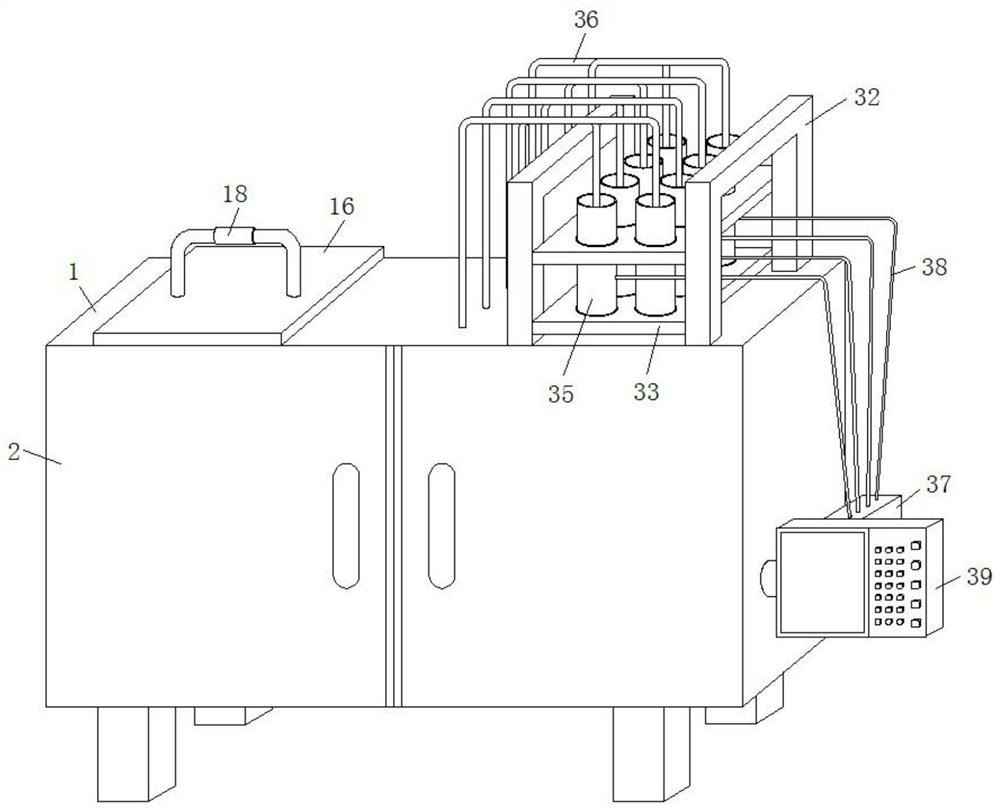

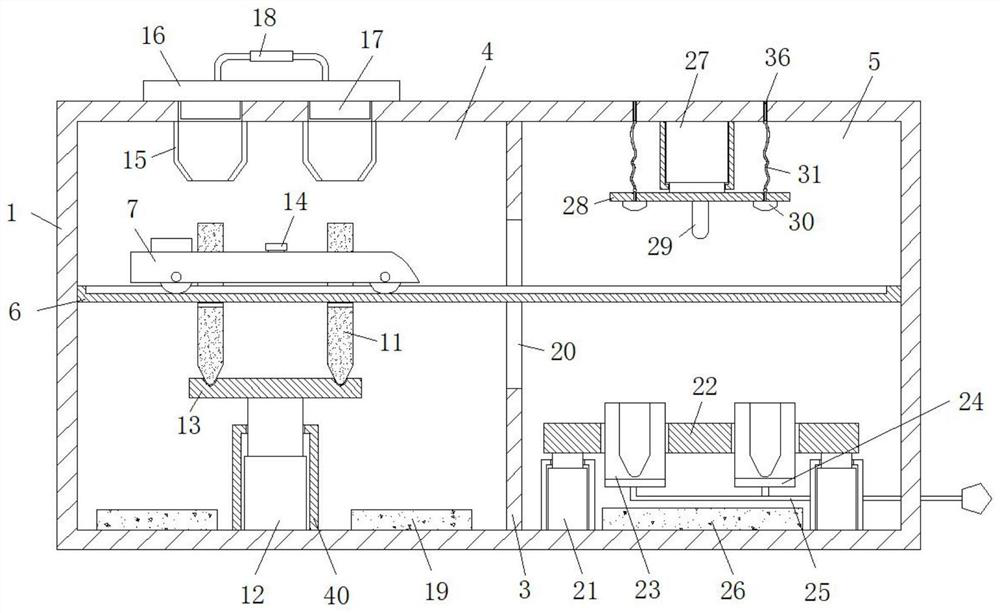

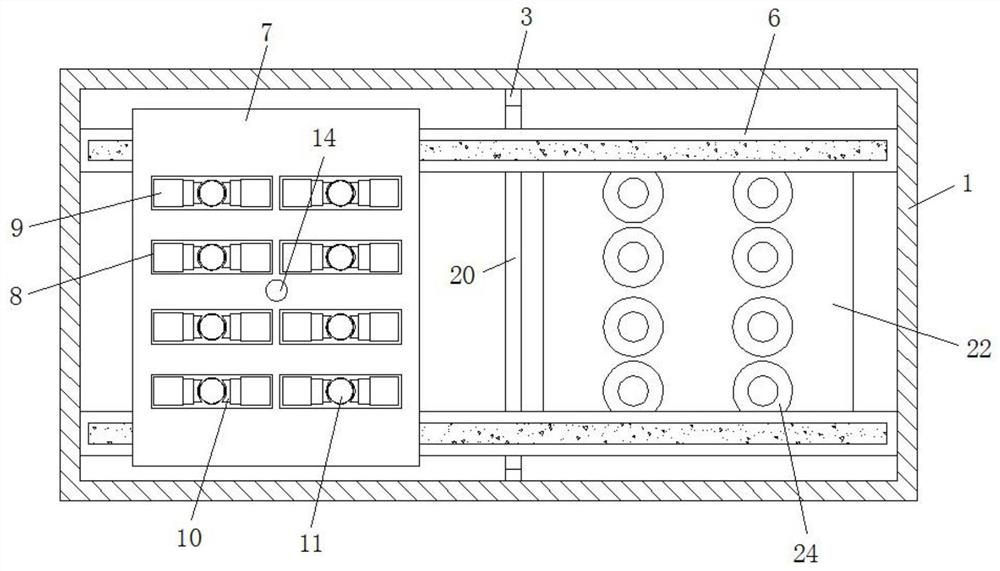

[0029] refer to Figure 1-4, a batch testing equipment for platinum-rhodium thermocouple processing, including a sealing door 2 connected to both sides of the front end of a testing box 1 through hinge rotation, and a partition 3 fixedly connected to the middle of the inner wall of the testing box 1, and the partition 3. Divide the verification box 1 into a preheating chamber 4 and a test chamber 5. The middle part of the inner wall on both sides of the verification box 1 is fixed with a holding plate 6. The upper end of the holding plate 6 is provided with rolling grooves, and rolling grooves are installed inside the rolling grooves. There is a feeding trolley 7, and the middle part of the top surface of the feeding trolley 7 is provided with a rectangular groove 8, and the inner walls of both sides of the rectangular groove 8 are fixed with an electric telescopic rod-9 by screws, and the output of the electric telescopic rod-9 is all fixed by screws. A clamping block 10 is c...

Embodiment 2

[0032] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, a temperature sensor is provided in the preheating chamber 4 and the test chamber 5, and the output end of the temperature sensor is electrically connected to the input end of the controller 37, and the electric telescopic rod 19, cylinder 1 12, cylinder 2 21 and electric telescopic rod 2 27 output ends are all electrically connected with the controller 37, and the model of the controller 37 is NE040S.

[0033] In this embodiment, temperature sensors are provided in the preheating chamber 4 and the testing chamber 5, so as to facilitate detection of the real-time temperature in the preheating chamber 4 and the testing chamber 5, and then provide movement for the high-quality detection of the platinum-rhodium thermocouple. guarantee, the output ends of electric telescopic rod one 9, cylinder one 12, cylinder two 21 and electric telescopic rod two 27 are electrically connected...

Embodiment 3

[0035] Such as figure 2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the outer sides of cylinder one 12, cylinder two 21 and electric telescopic rod two 27 are all fixedly connected with heat-insulating barrels 40, and the heat-insulating barrels 40 are all fixedly connected by screws. On the inner wall of the verification box 1.

[0036] In this embodiment, by placing the first cylinder 12, the second cylinder 21 and the second electric telescopic rod 27 in the heat insulation barrel 40, the first cylinder 12, the second cylinder 21 and the second electric telescopic rod 27 work more stably, greatly extending the The service life of cylinder one 12, cylinder two 21 and electric telescopic rod two 27.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com