A Method of Collecting All Surface Images of Spherical Materials Using Concave Mirror

A surface image and concave mirror technology, applied in image communication, color TV parts, TV system parts, etc., can solve problems such as large amount of calculation, three images cannot cover the entire spherical surface, and long data processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below with reference to the accompanying drawings and embodiments.

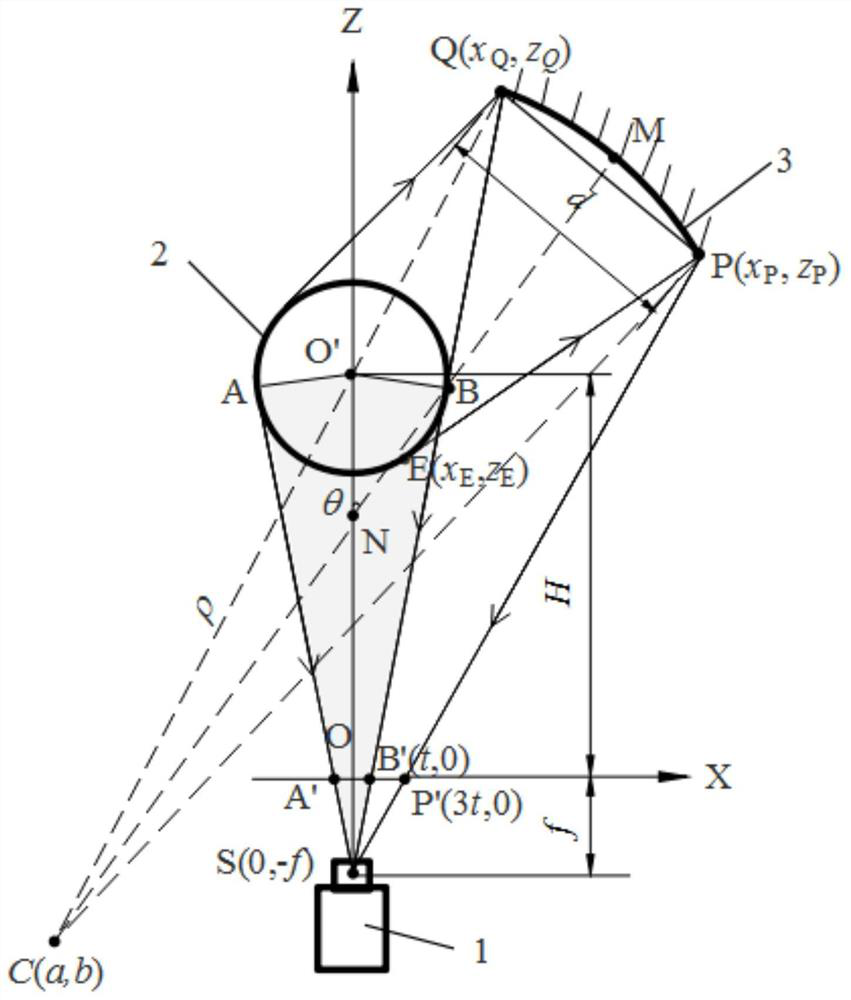

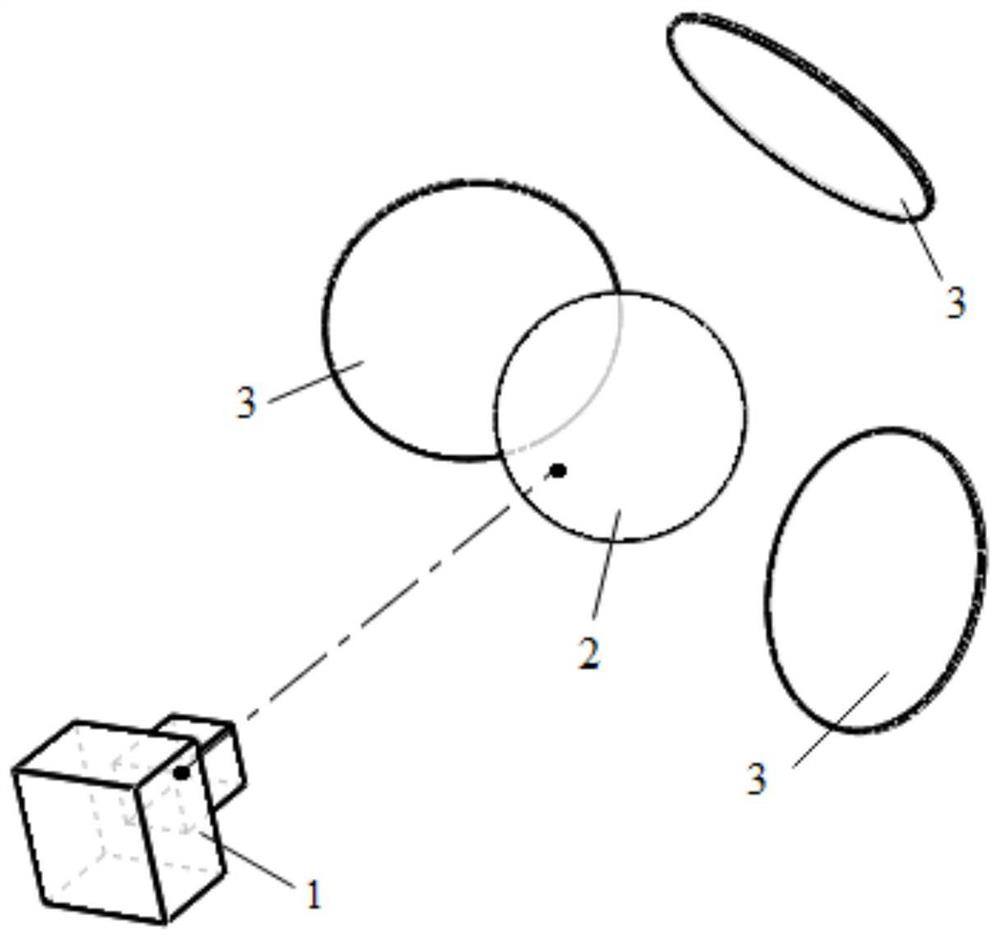

[0072] figure 1 It is a schematic diagram of the imaging model of the concave mirror 3, in which the camera 1, the optical center S of the camera 1, the spherical material 2, the spherical center O' of the spherical material 2 and the curvature center C of the concave mirror 3 are located in the same plane, and the equivalent imaging is established. The plane coordinate system O-XZ where the planes coincide. Wherein, the Z axis coincides with the optical axis of the camera 1, and the X axis is parallel to the long side of the photosensitive element of the camera 1—CCD (Charge Coupled Device, Charge Coupled Device).

[0073] point P(x P ,z P ), point Q(x Q ,z Q ) is the reflection point on the concave mirror 3, and the point Q(x Q ,z Q ), the normal passes through the center of spherical material 2, which satisfies the equations:

[0074]

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com