Control method of electric tool

A control method and technology of electric tools, applied in the direction of electrical components, circuit devices, emergency protection circuit devices, etc., can solve problems such as high cost, troublesome manufacturing, and complex structure of mechanical clutches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

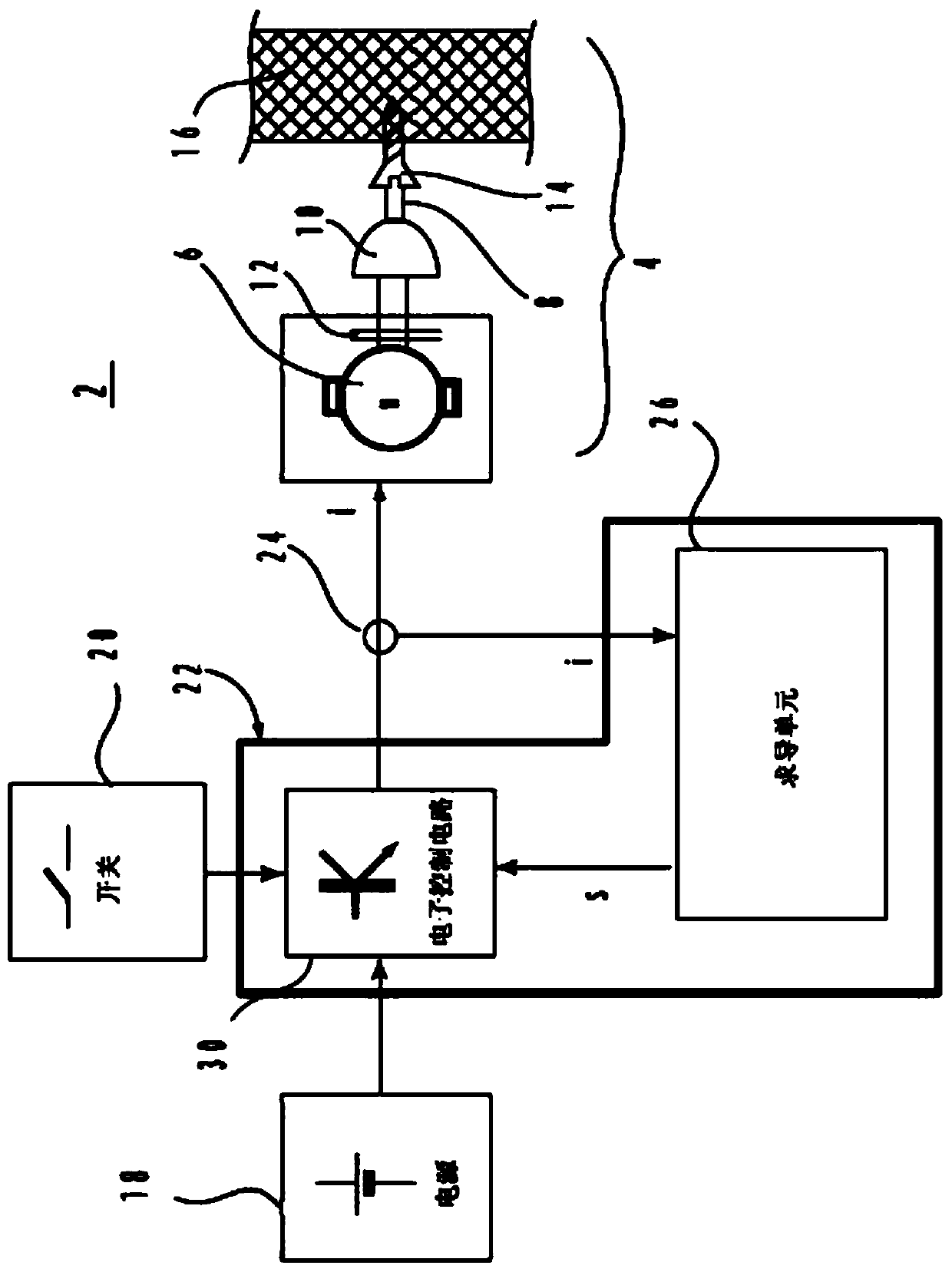

[0025] An embodiment of the present invention provides a control method of an electric tool, such as Figure 6 As shown, the method includes the following steps:

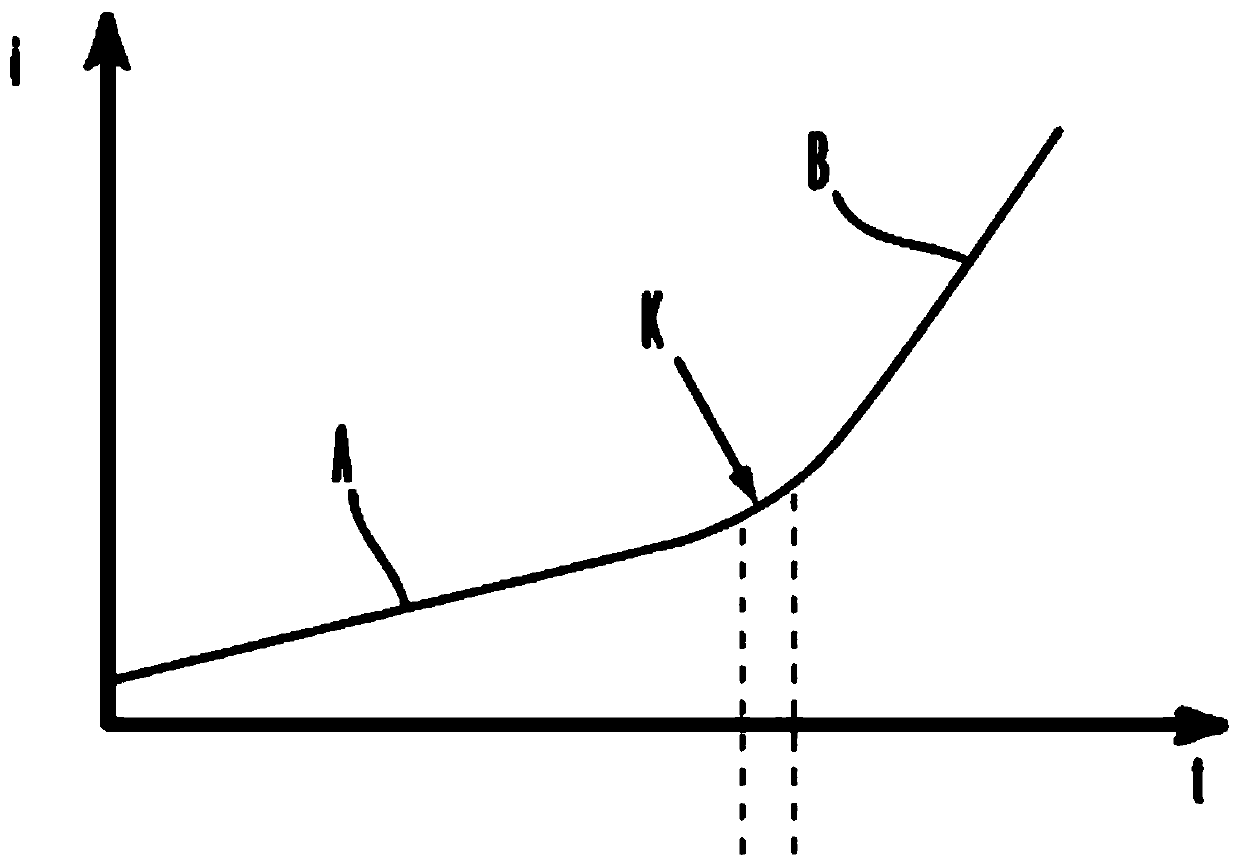

[0026] S1, measuring the parameters used to represent the load of the output shaft that change with time, the parameters include a variety of parameters, such as current, voltage, speed, etc. The measurement method may be sampling at a fixed period.

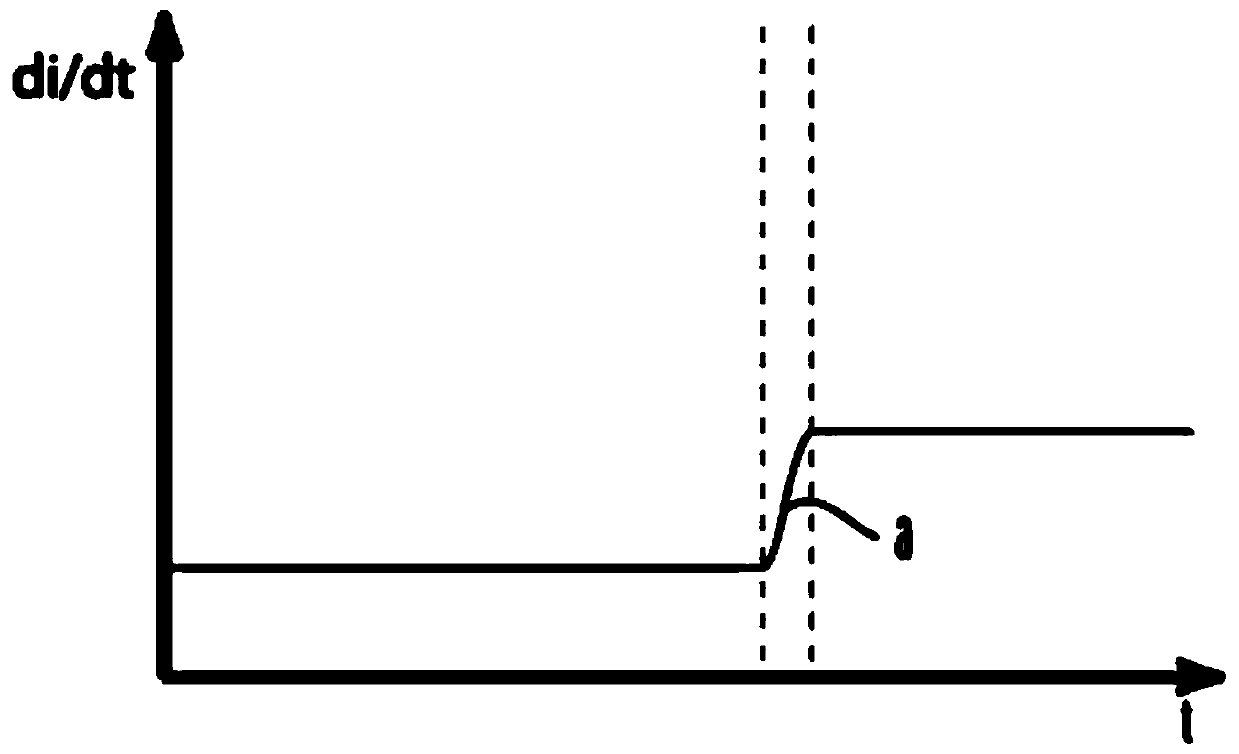

[0027] S2, obtain the derivative of the parameter with respect to time, this derivative is actually figure 1 The slope of the middle curve. There are many ways to calculate the derivative, which will be described in detail below.

[0028] S3, judging whether the obtained derivative is greater than a derivative threshold, the derivative threshold may be a predetermined and stored value, and the derivative threshold may be one or more. When the obtained derivative is greater than the derivative threshold, step S4 is executed; otherwise, the derivative is continuously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com