Modular rigid ceramic tile assembly

A ceramic tile and modular technology, which is applied to aircraft parts, fuselage, transportation and packaging, etc., can solve the problems of a large number of rigid ceramic tiles, the inability to meet the rapid deployment of spacecraft, and short launch intervals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

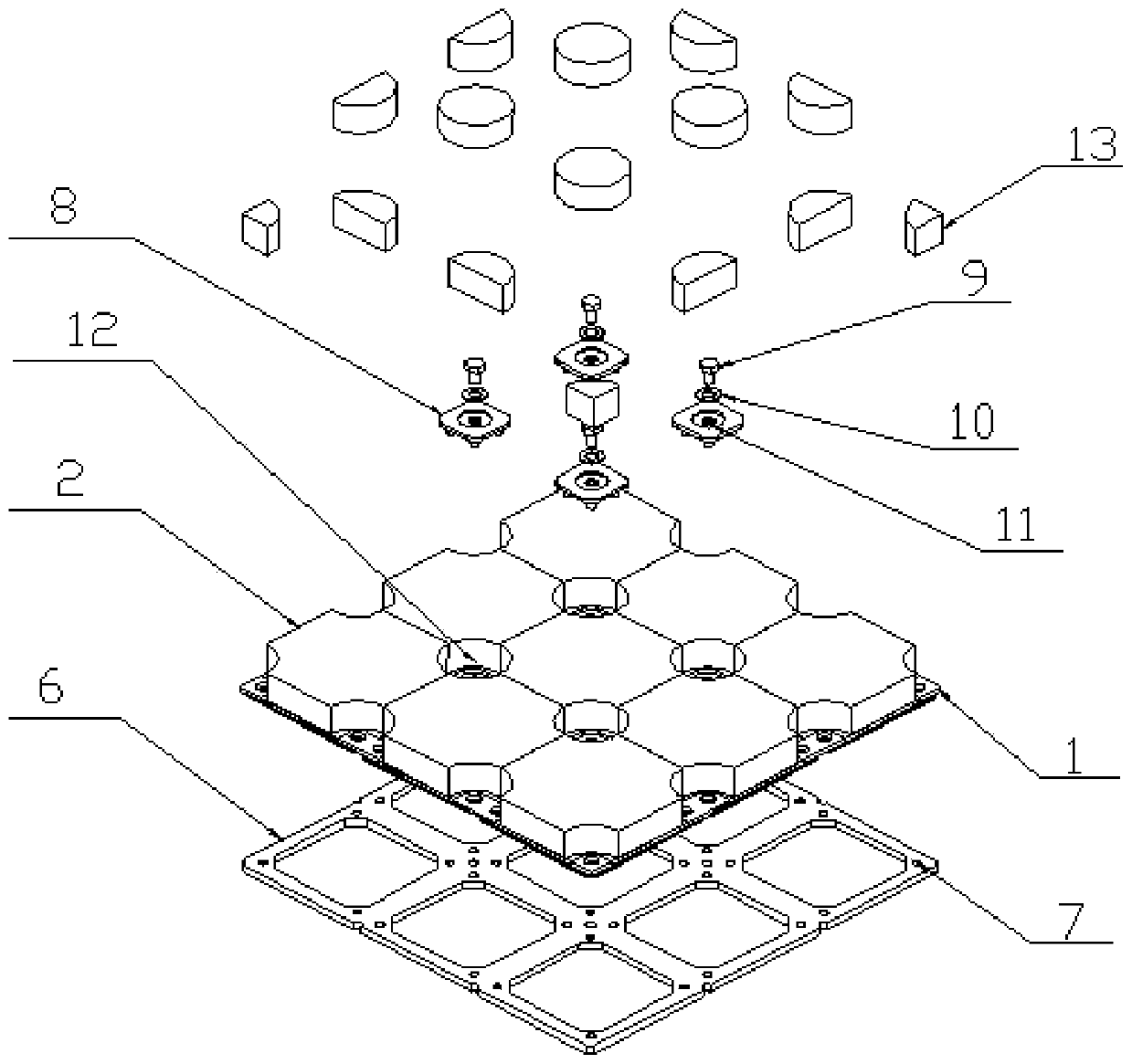

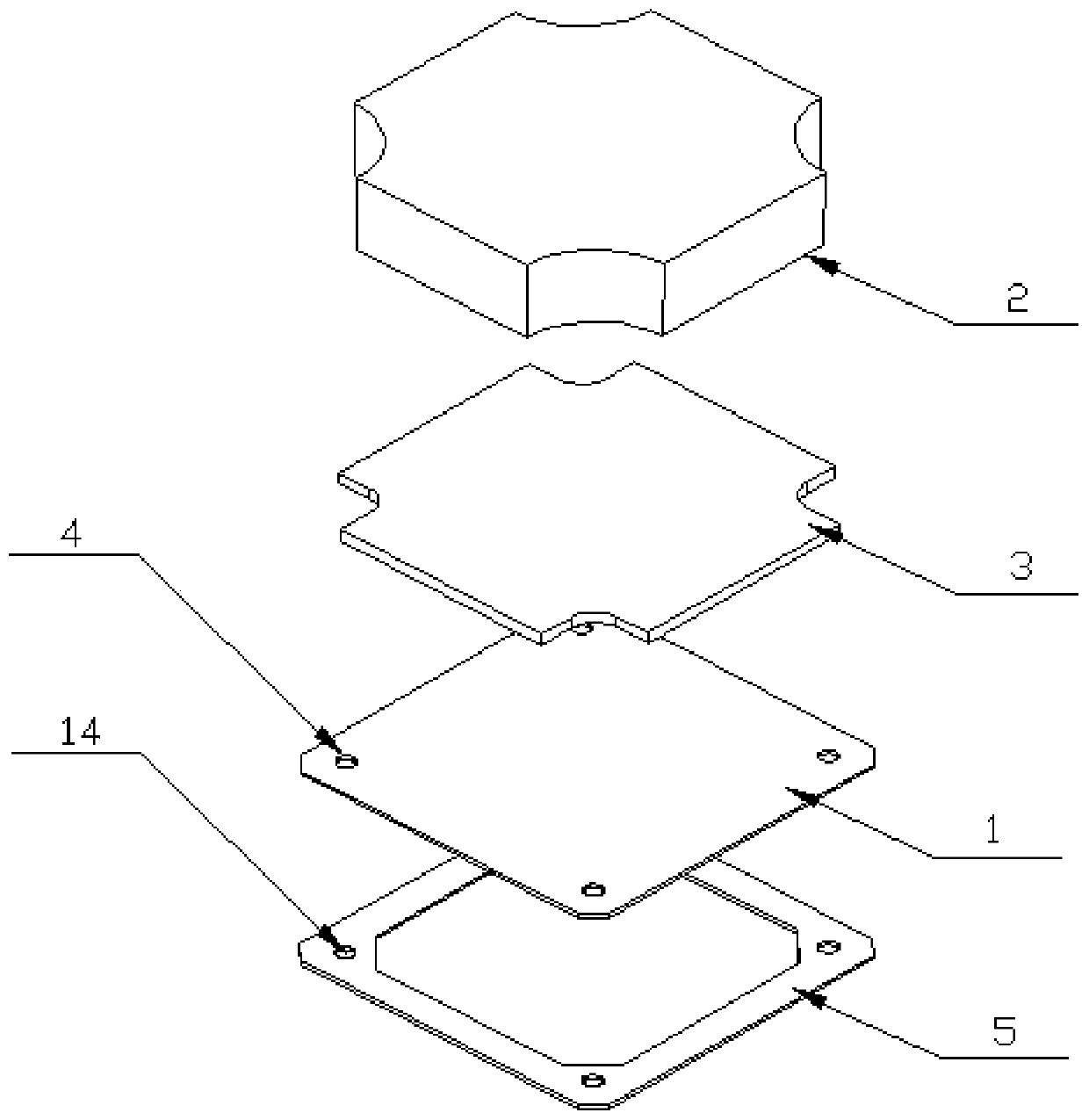

[0031] Please refer to figure 1 and figure 2 The schematic structural diagram of the first embodiment of a modular rigid ceramic tile assembly provided by the application is shown, including: a single ceramic tile prefabricated body and a fixing structure for integrating the single ceramic tile prefabricated body;

[0032] The single ceramic tile prefabricated body includes: a metal base plate 1 and a ceramic tile 2 arranged on the metal base plate 1; the cross-sectional shape of the metal base plate 1 is a square structure, and holes 4 are respectively provided at four right angles thereof The lower surface of the ceramic tile 2 is provided with a strain isolation pad 3; the ceramic tile 2 and the strain isolation pad 3 are both provided with an arc-shaped hole angle corresponding to the hole 4;

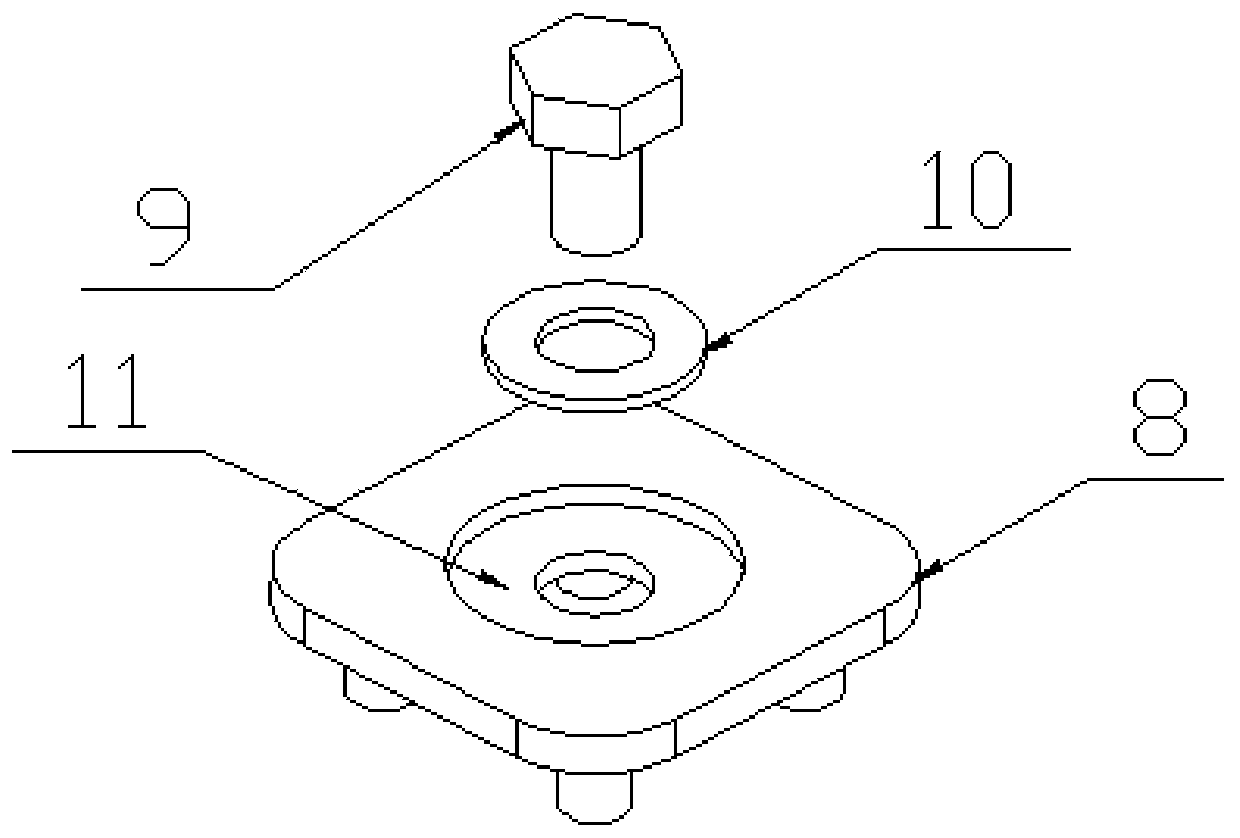

[0033] The fixed structure includes: a metal skeleton 6 and a fixed insert 8; at least four ring frames are arranged on the metal skeleton 6; four evenly arranged positioning hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com