Titanium dioxide for outdoor paint and preparation method

A technology of titanium dioxide and coatings, applied in the direction of polyester coatings, chemical instruments and methods, coatings, etc., can solve the problems of thixotropy, poor slurry filtration and washing performance, false thickening, etc., and achieve improved weather resistance and light shielding Catalytic activity, effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

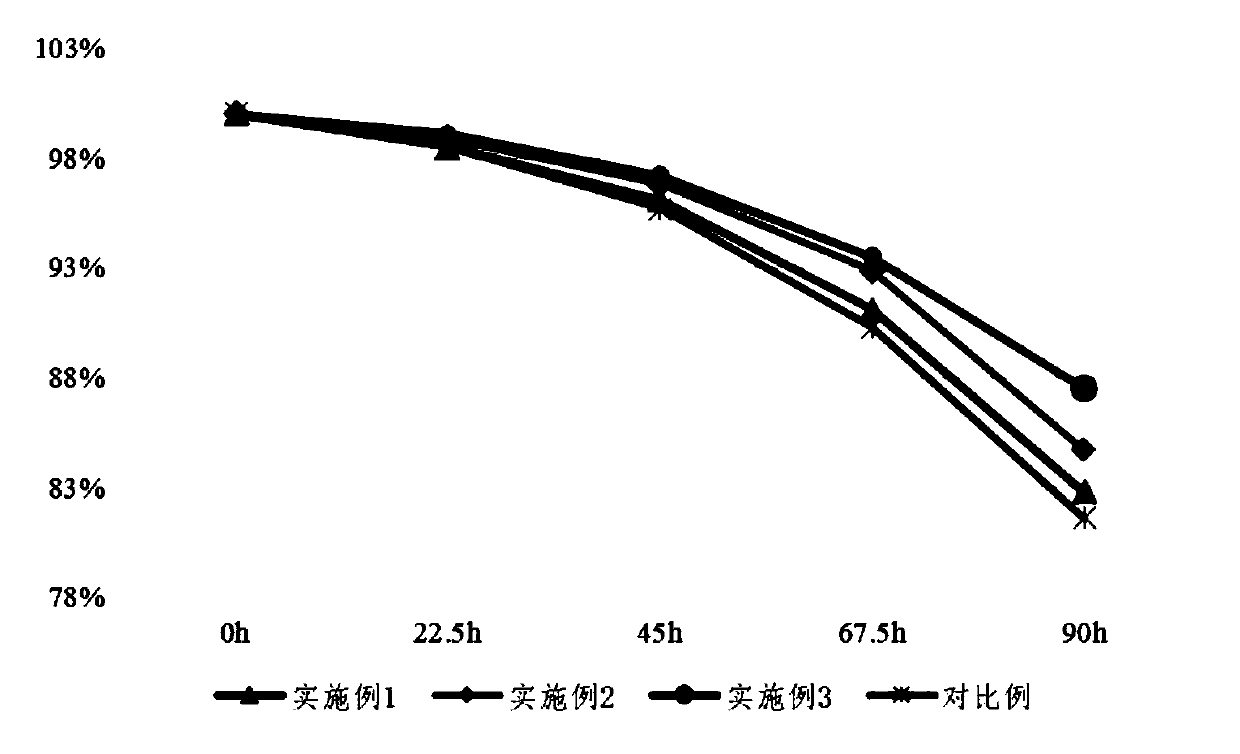

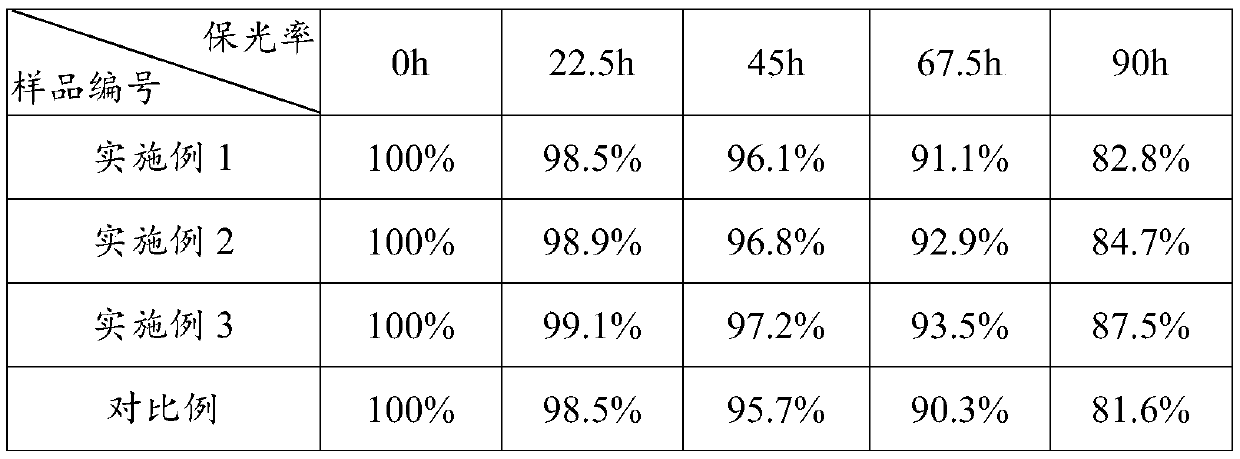

Embodiment 1

[0058] Pump the pulverized and sand-milled slurry into the coating tank, add water to dilute the slurry concentration to 300g / L (based on TiO 2 At the same time, the slurry was heated to 60°C with steam; within 30 minutes, TiOCl, which accounted for 0.1% of the mass fraction of titanium dioxide in the slurry, was added in parallel. 2 solution (with TiO 2 meter) and 0.1% ZrOCl 2 solution (as ZrO 2 meter), and use NaOH to control the pH of the slurry to 8.0, and homogenize for 20 minutes; raise the temperature of the slurry to 90°C, adjust the pH of the slurry to 10.0 with NaOH solution, and add 1.0% Na within 20 minutes 2 SiO 3 solution (as SiO 2 meter), homogenize for 20min; use dilute H 2 SO 4 Adjust the pH of the slurry to 6.5 within 120 minutes, homogenize for 30 minutes; cool the slurry to 60°C, adjust the pH to 8.0, and add 0.1% NiSO 4 (as NiO) solution and X% NaAlO 2 solution (as Al 2 o 3 meter), and maintain the pH of the slurry at 8.0, until the NiSO 4 After...

Embodiment 2

[0064] Pump the pulverized and sand-milled slurry into the coating tank, add water to dilute the slurry concentration to 300g / L (based on TiO 2 At the same time, the slurry was heated to 60°C with steam; 0.3% TiOCl was added concurrently within 60 minutes 2 and 0.3% ZrOCl 2 , and use NaOH to control the pH of the slurry to 8.5, and homogenize for 30 minutes; raise the temperature of the slurry to 90°C, adjust the pH of the slurry to 10.2 with NaOH solution, and add 2.0% Na within 30 minutes 2 SiO 3 solution, homogenize for 30min; use dilute H 2 SO 4 Adjust the pH of the slurry to 6.8 within 120 minutes, homogenize for 30 minutes; cool the slurry to 60°C, adjust the pH to 8.3, and add 0.3% NiSO 4 (as NiO) solution and X% NaAlO 2 solution (as Al 2 o 3 meter), and maintain the pH of the slurry at 8.3, until the NiSO 4 After the solution has reacted completely, (4-X)% NaAlO 2 solution and dilute H 2 SO 4 Parallel flow, the total addition time of sodium metaaluminate is ...

Embodiment 3

[0066] Pump the pulverized and sand-milled slurry into the coating tank, add water to dilute the slurry concentration to 300g / L (based on TiO 2 At the same time, the slurry was heated to 60°C with steam; 0.5% TiOCl was added concurrently within 60 minutes 2 and 0.5% ZrOCl 2 , and use NaOH to control the pH of the slurry to 9.0, and homogenize for 30 minutes; raise the temperature of the slurry to 90°C, adjust the pH of the slurry to 10.3 with NaOH solution, and add 3.0% Na within 30 minutes 2 SiO 3 solution, homogenize for 30min; use dilute H 2 SO 4 Adjust the pH of the slurry to 6.8 within 150 minutes, homogenize for 30 minutes; cool the slurry to 60°C, adjust the pH to 8.5, and add 0.5% NiSO 4 solution with X% NaAlO 2 solution, and maintain the pH of the slurry at 8.5, until the NiSO 4 After the solution has reacted completely, (5-X)% NaAlO 2 solution and dilute H 2 SO 4 Parallel flow, adding sodium metaaluminate for 120 minutes, homogenizing for 30 minutes; within ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap