Low-carbon alloy steel vacuum carburizing technology

A low-carbon alloy steel and vacuum carburizing technology, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of a large number of carbides, so as to improve the service life and avoid subsequent fracture and cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

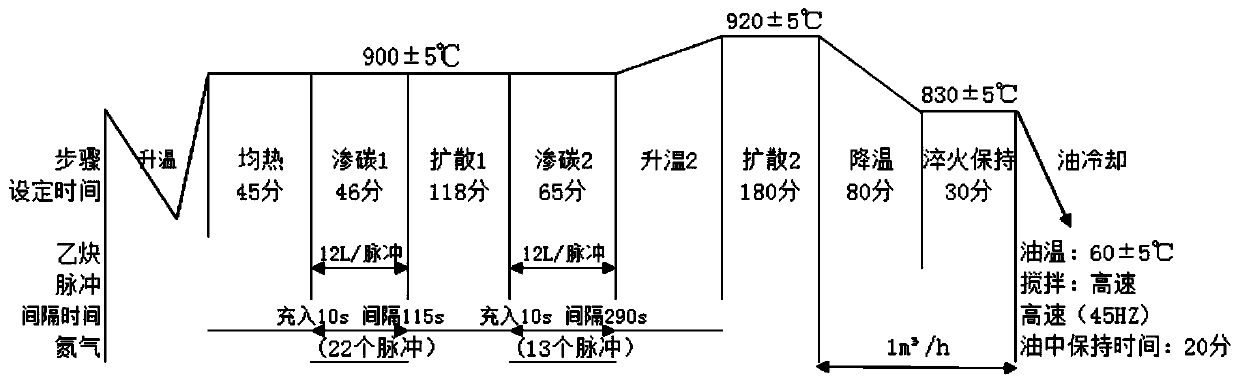

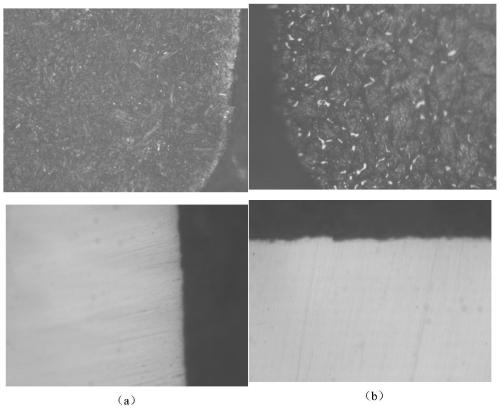

[0038] Such as figure 1 Carburizing and quenching the electric tool parts produced by a certain company. The material is low-carbon alloy steel 20Cr2Ni4 (carbon 0.17-0.23%). After cleaning the product, it starts carburizing and quenching. After reaching 900±5°C, soak for 45 minutes, and then carry out carburizing diffusion. The first stage of carburizing diffusion is 46 minutes and 118 minutes. The acetylene is 12L / pulse, a total of 22 pulses, each pulse of acetylene is passed through for 10s , the interval is 115s, the second stage of carburizing is also 12L / pulse of acetylene, the time is 65 minutes, each pulse of acetylene is passed through for 10s, the interval is 290s, a total of 13 pulses, and then the temperature is raised to 920±5°C and diffused for 180 minutes, and finally the temperature is lowered to 830±5℃ for 30 minutes, then oil cooling, quenching oil temperature 60±5℃, keep in oil for 20 minutes. Nitrogen protection is carried out during the cooling stage and q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com