Dorsal bar system

A back corrugated and systematic technology, which is applied to the joints of formwork/formwork/work frame, the preparation of building components on site, construction, etc., can solve the problems of poor construction convenience, low utilization rate, and large loss , to achieve the effect of saving renovation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

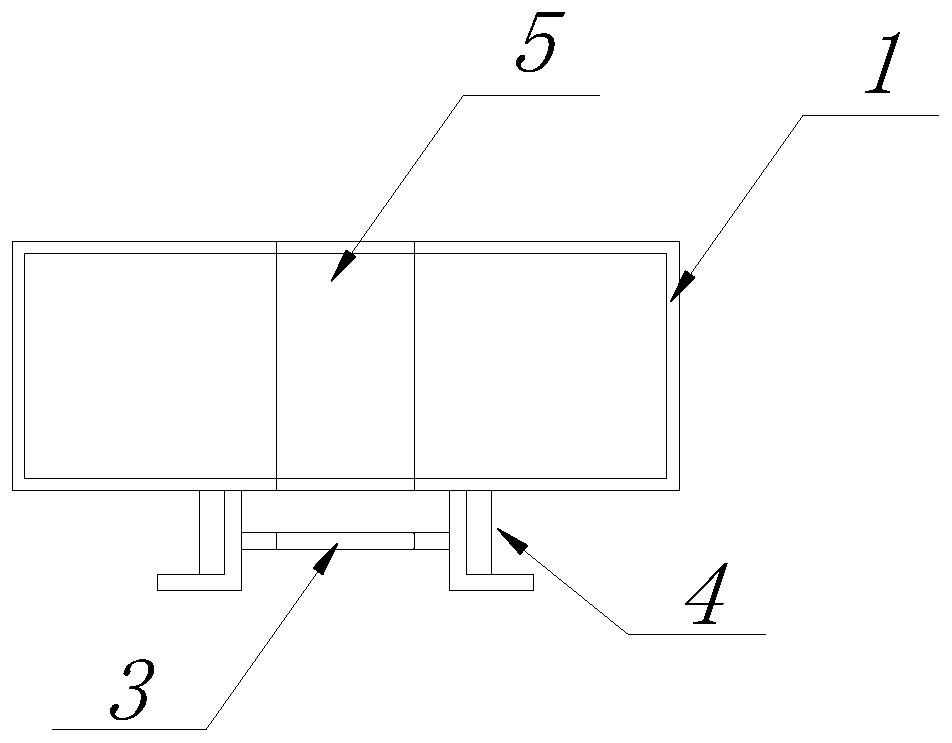

[0027] A preferred embodiment of the present invention will be described below in conjunction with the accompanying drawings, and the technical solution in a preferred embodiment of the present invention will be clearly and completely described.

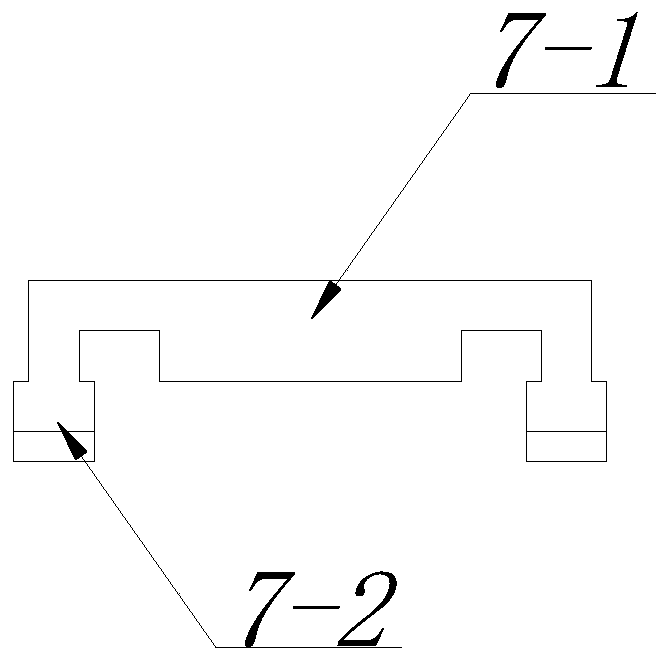

[0028] The present invention includes several back corrugated monomers, several U-shaped fixtures 7, several large female corner connectors, several small female corner connectors and several male corner connectors.

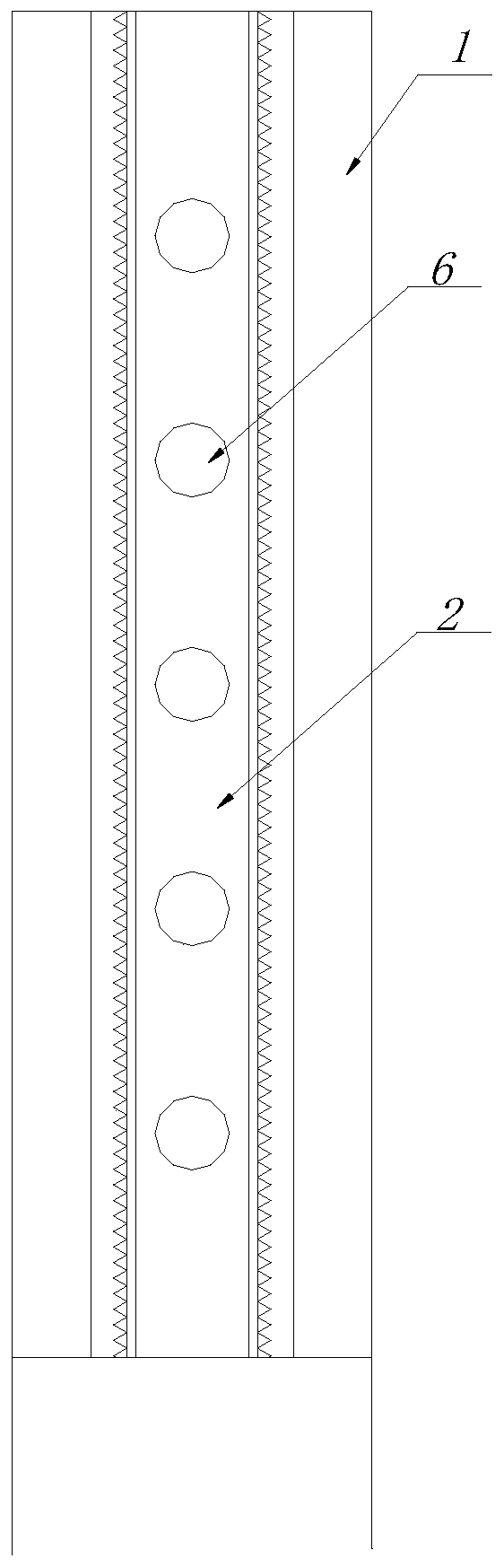

[0029] See figure 1 and figure 2 , the back corrugated monomer comprises a rectangular tube 1, the tube wall of the rectangular tube 1 is provided with at least one I-shaped structural part 2, and the width of the I-shaped structural part 2 is smaller than the width of the rectangular tube 1; the I-shaped structure The part 2 includes a connecting plate 3 , two sides of the connecting plate 3 are symmetrically provided with clamping plates, and the clamping plates are bent outward to form a clamping groove 4 .

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com