Eccentric rotation following sealing device for rotary blowout preventer

A technology of rotating blowout preventer and eccentric rotation, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., and can solve inevitable problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

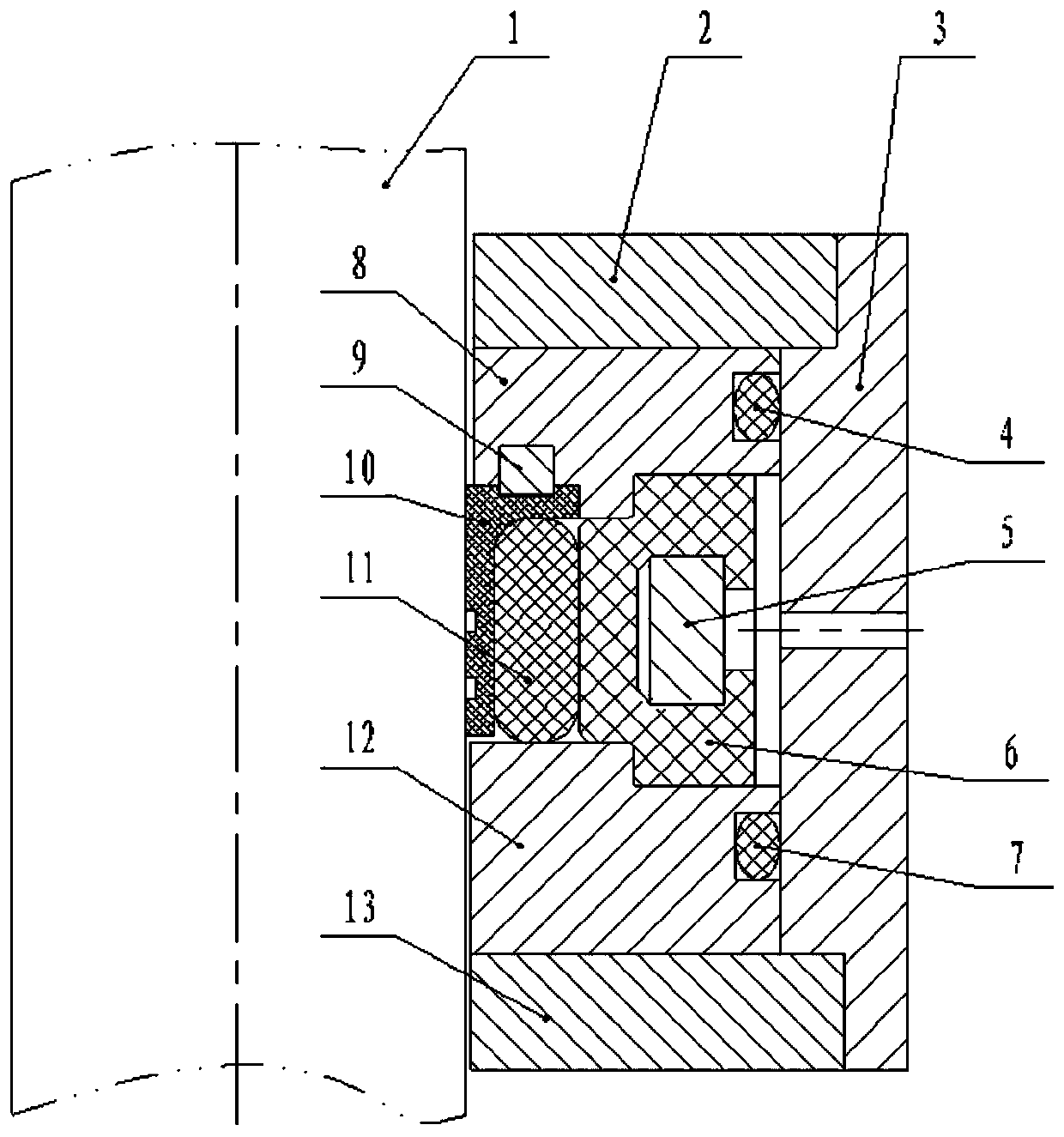

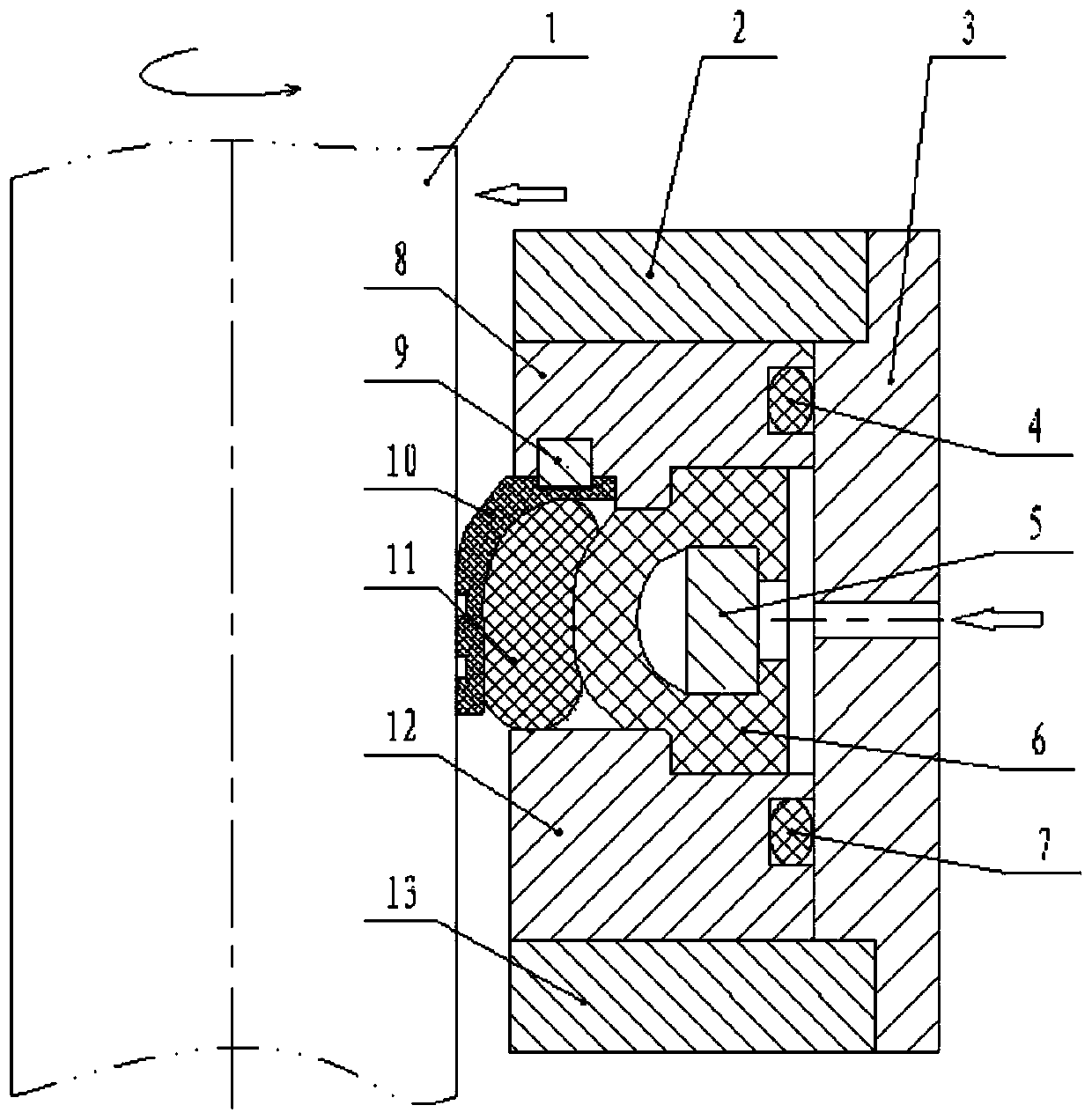

[0028] like figure 1 As shown, a rotary blowout preventer eccentric rotation following sealing device includes a casing 3 set outside the rotating shaft 1, the upper and lower ends of the casing 3 are respectively installed with an upper cover 2 and a lower cover 13, the upper cover 2 A sealing cavity is formed between the lower cover and the lower cover 13, and the following seal 10 and the compensating seal 6 are sequentially set in the sealing cavity from the inside to the outside. A hydraulic cavity is formed between the inner sides of the casing 3, and the side wall of the casing 3 is provided with a liquid inlet hole communicating with the hydraulic cavity.

[0029] The follower seal 10 is made of wear-resistant and pressure-resistant material, and its inner side is provided with a serrated sealing lip which contacts with the cylindrical surface of the rotating shaft 1 to form a sealing surface, and the rotating shaft 1 rotates to perform rotary sealing. The compensatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com