Garbage input mechanism for environment-friendly and efficient garbage pyrolysis device

A technology of input mechanism and garbage, applied in lighting and heating equipment, combustion method, combustion type and other directions, which can solve the problems of not easy to swing and convey garbage, stick to each other, and not easy to disperse garbage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

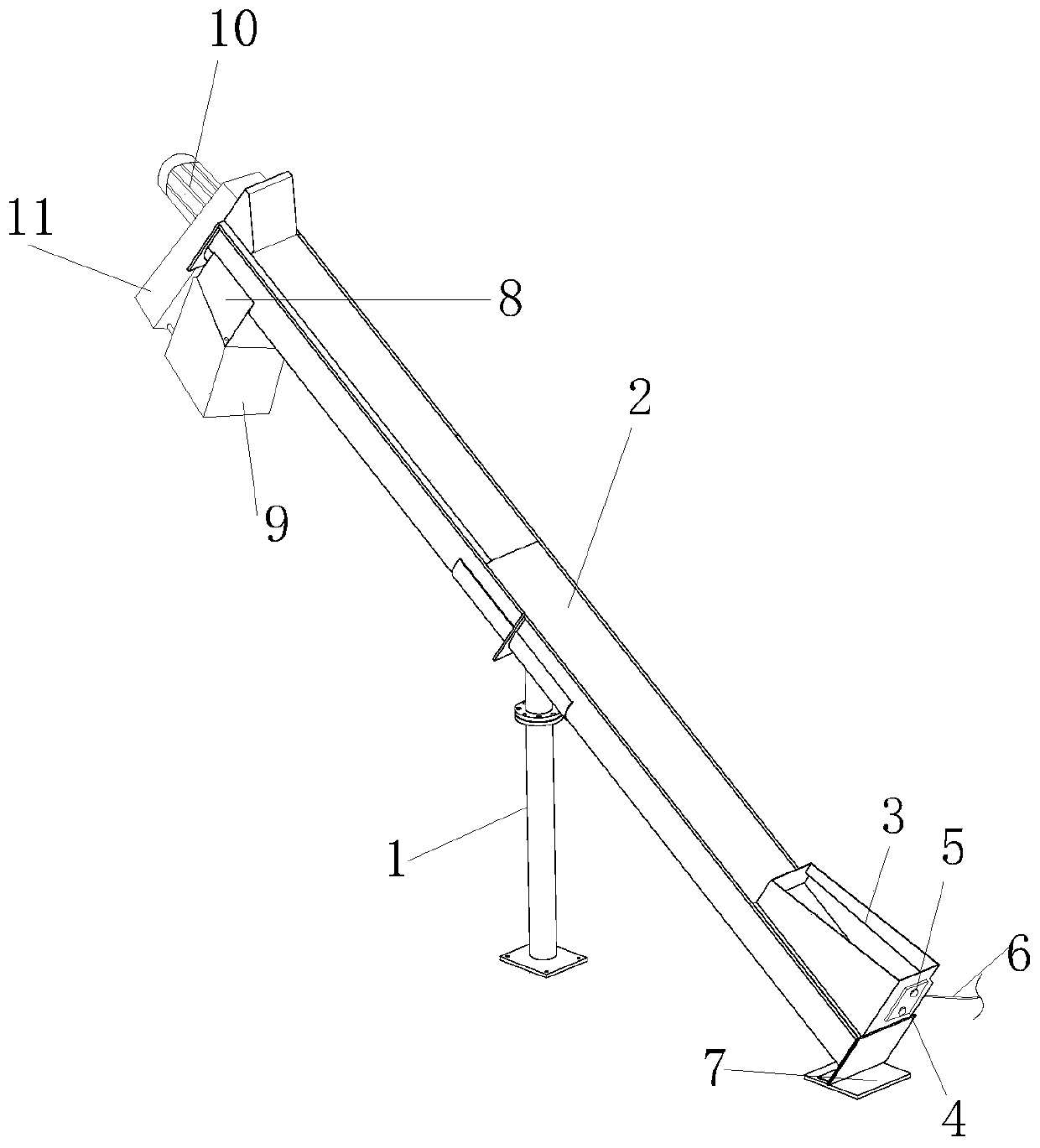

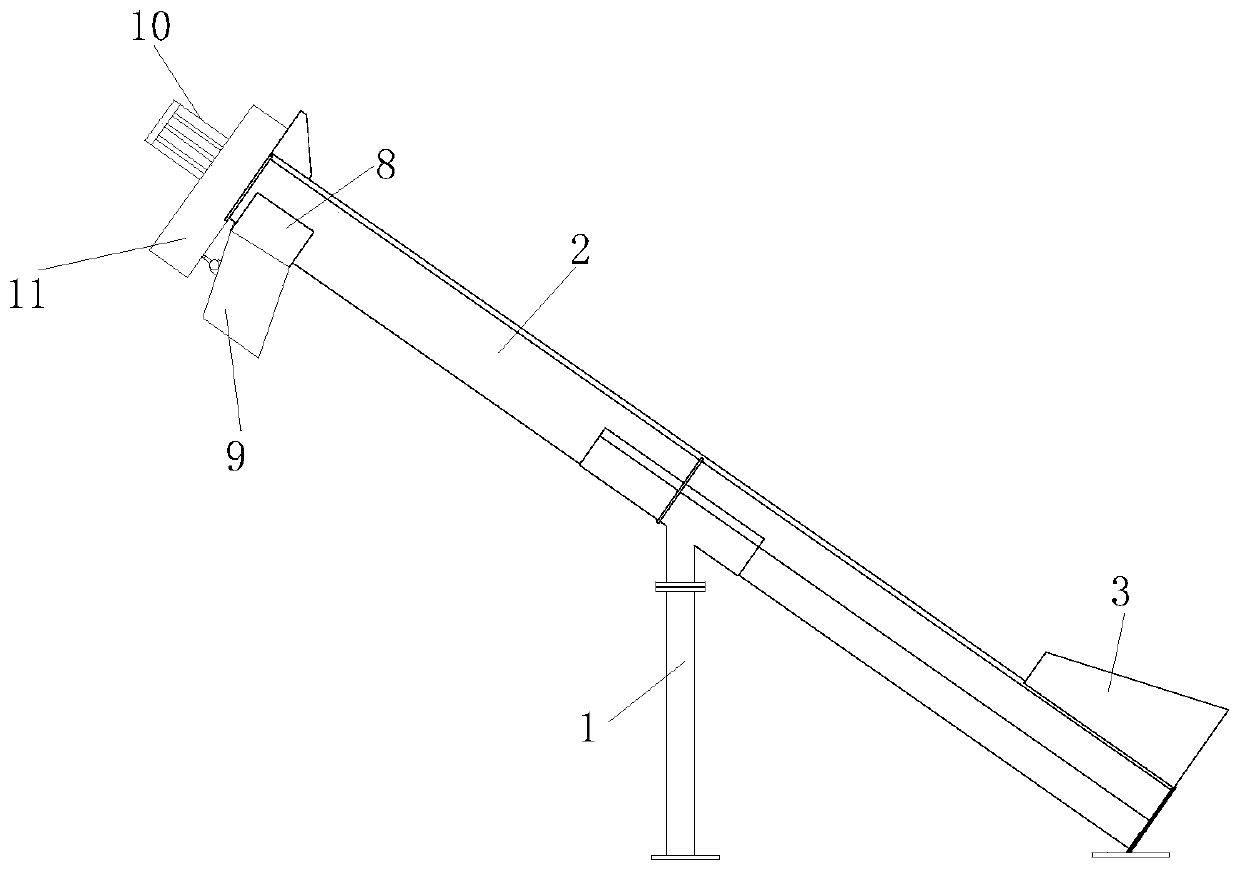

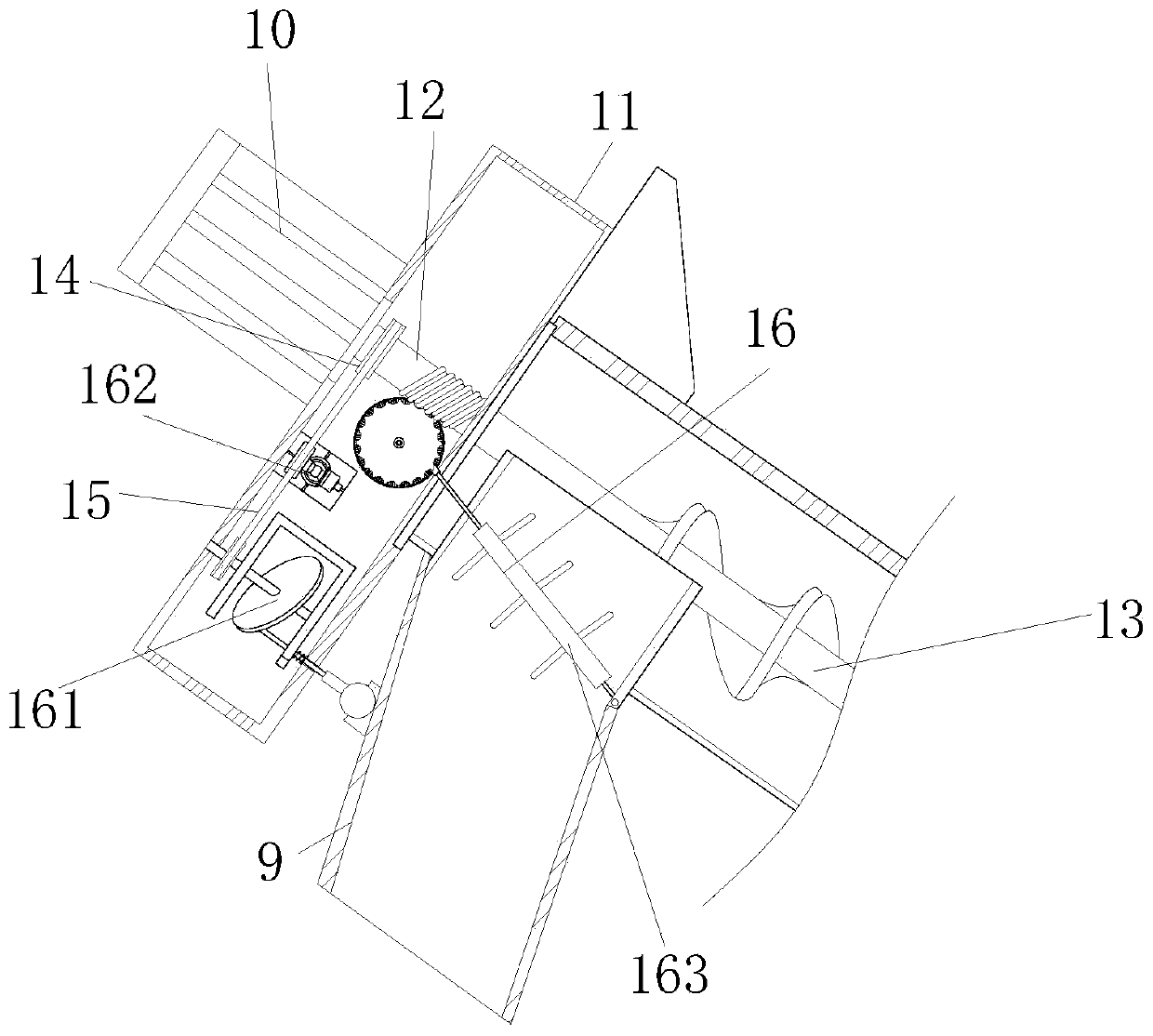

[0033] see figure 1 and figure 2 , the present invention provides a waste input mechanism of an environmentally friendly and efficient pyrolysis device for waste through improvement, including a pillar 1, a delivery pipe 2, a feed hopper 3, a bottom plate 7, a discharge hopper 8, a motor 10, a protection frame 11, and a rotating shaft 12. The feeding auger 13 and the swing breaking device 16, the top of the pillar 1 is fixed with the conveying pipe 2 by electric welding, the conveying pipe 2 is seamlessly connected with the bottom edge of the feeding hopper 3, and the right end of the feeding hopper 3 is provided with a control panel 4, The right end of the control panel 4 is equipped with a button 5, the rear end of the delivery pipe 2 is fixed with a power lead 6, the delivery pipe 2 and the top of the bottom plate 7 are fixed as a whole, the delivery pipe 2 is connected with the top of the discharge bucket 8, and the discharge bucket 8 is connected to the conveyor through ...

Embodiment 2

[0039] The present invention provides a garbage input mechanism of an environmentally friendly and high-efficiency pyrolysis device through improvement. The upper end of the breaking roller 1637 is provided with a breaking rod 16371, and there are six breaking rods 16371, which are equidistant along the upper end of the breaking roller 1637. The distribution is beneficial to play the advantage of breaking up the garbage. The upper end of the pressing bar 1623 is provided with a chute 16231, and the stop bar 1625 slides and cooperates with the inner side of the chute 16231, which is beneficial to make the pressing bar 1623 move up and down.

[0040] The present invention provides a waste input mechanism of a garbage environmental protection high-efficiency pyrolysis device through improvement, and its working principle is as follows;

[0041] First, before use, place the garbage input mechanism of the garbage environmental protection and high-efficiency pyrolysis device horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com