Closed-loop control gas heater based on wide-range oxygen sensor

A technology of gas heater and oxygen sensor, which is applied in the direction of combustion control, electrical control, engine control, etc. It can solve the problems of insufficient adjustability of gas heating, improve the adjustable range of heat release power, and reduce vehicle heating fluctuations , Convenient power matching and model selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

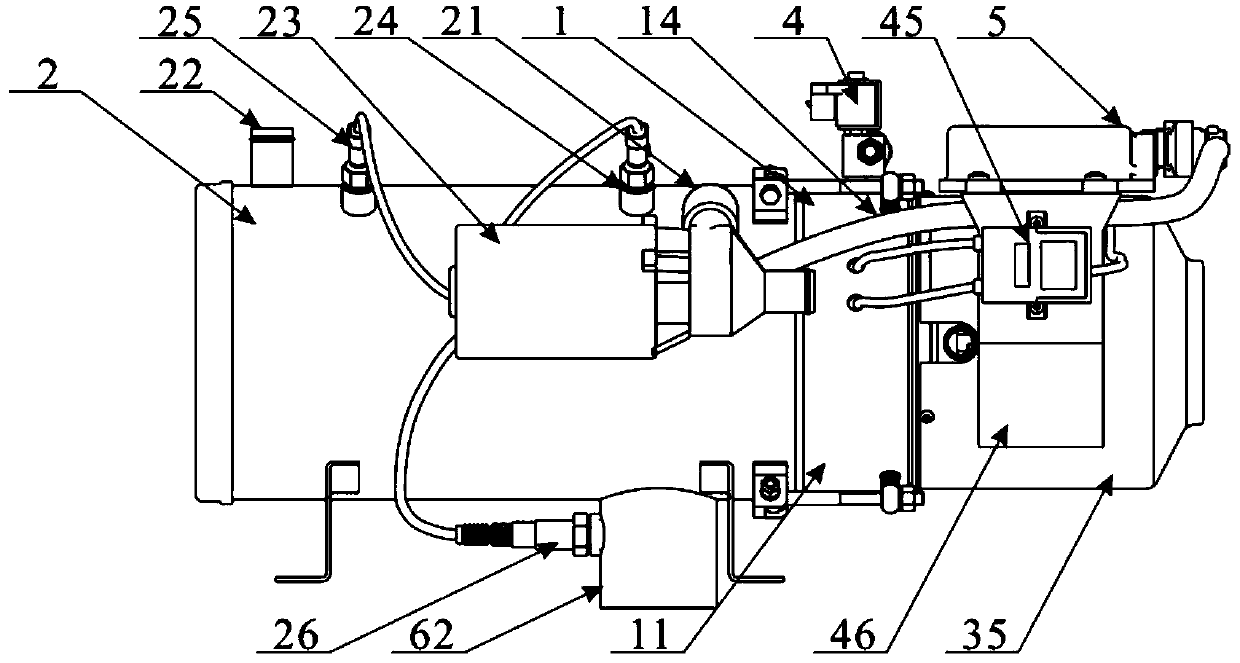

[0017] Such as figure 1 As shown, it is the front view of the gas heater based on the closed-loop control of the wide-area oxygen sensor.

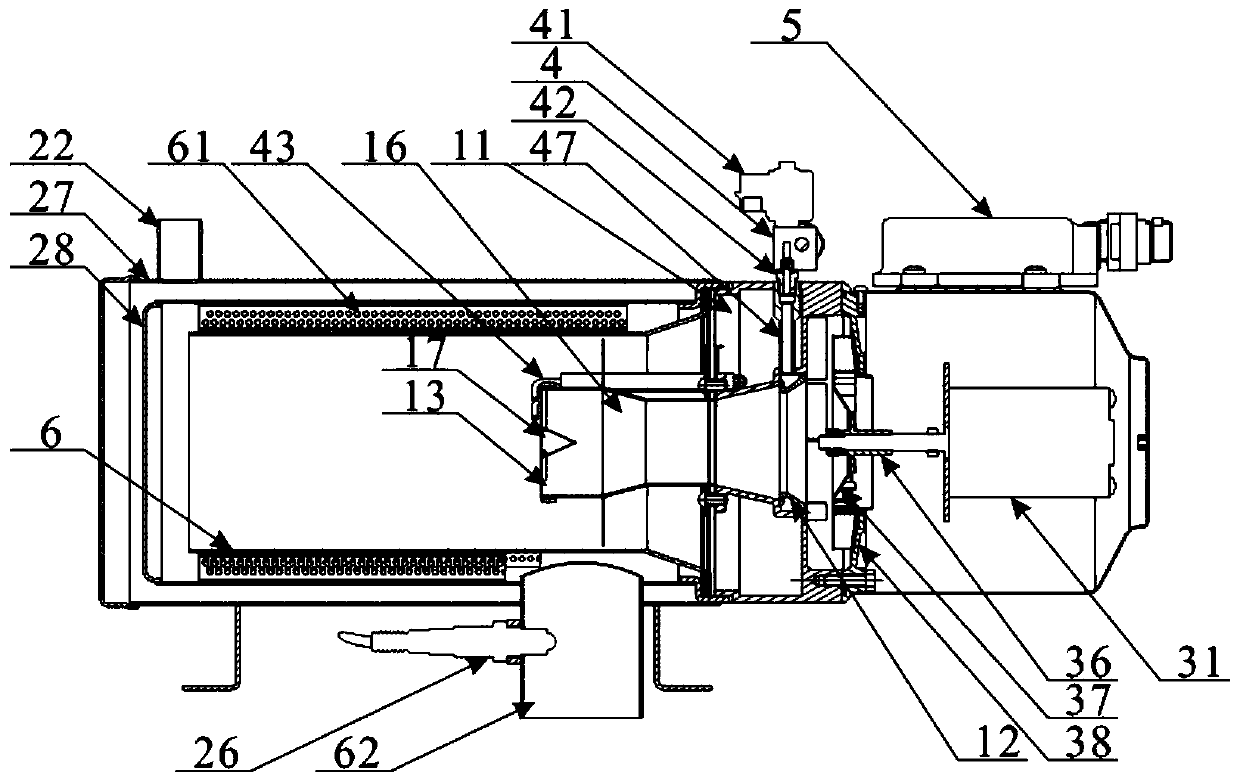

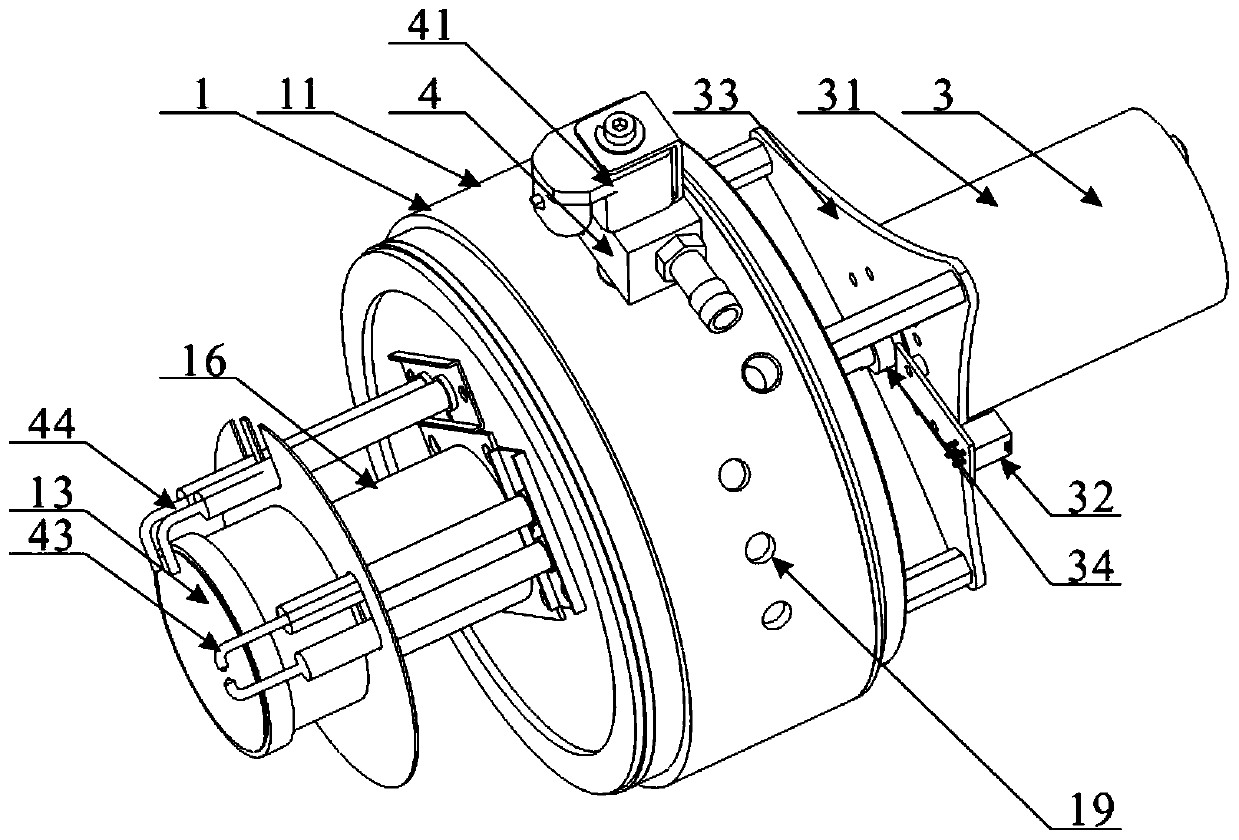

[0018] The gas heater based on wide-area oxygen sensor closed-loop control of the present invention includes a burner 1, and a mixing core 12 and a mixing cylinder 16 connected to each other are arranged in the burner 1; a fan assembly 3 is installed at one end of the burner 1, and the fan assembly Component 3 includes a fan motor 31 , and the output end of the fan motor 31 is located in the burner 1 and is provided with a blower disk 37 .

[0019] The burner 1 is provided with a spray rail assembly 4, which includes a gas nozzle 41; the burner 1 is provided with a mixing core 12 and a mixing cylinder 16 connected to each other; the other end of the burner 1 is provided with a flame ion sensor 44 and the ignition pin 43, the ignition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com