Coating device and disposable hygienic product manufacturing equipment

A wrapping device and wrapping technology, applied in applications, clothing, underwear, etc., can solve the problems of narrow adjustment range, inconvenient use, inability to adapt to the core, etc., and achieve the effect of high adjustment accuracy and large range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

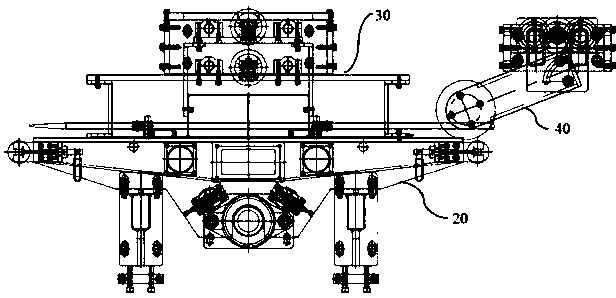

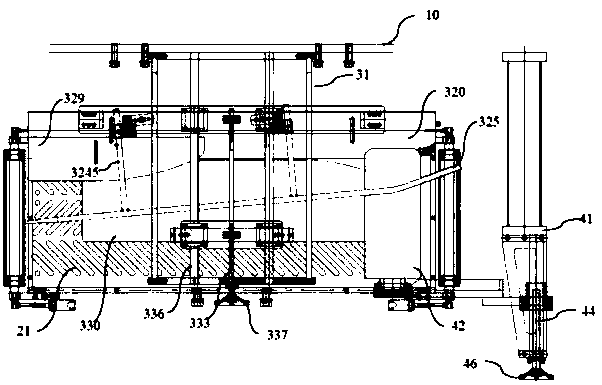

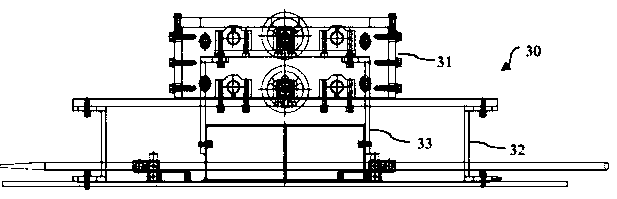

[0030] Please refer to Figure 1-Figure 2 , the embodiment of the present invention provides a wrapping device, which is used for folding and wrapping cores and the like during the manufacturing process of products such as disposable hygiene products, and the wrapping device includes a wrapping module 30 .

[0031] The cladding module 30 includes a first bracket 31 and a folding assembly 32 and a pressing plate assembly 33 arranged on the first bracket 31. The folding assembly 32 includes a folding plate 320 and a folding plate adjustment device. The pressing plate assembly 33 includes a pressing plate 330 and a pressing plate assembly 33. Pressing plate adjustment device, the folding plate 320 and the pressing plate 330 are horizontally spaced apart, the folding plate adjusting device is arranged above the folding plate 320, and is used to adjust the position of the folding plate 320 in the horizontal direction, and the pressing plate adjusting device is arranged on the pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com