Separating element and unit, filter element, housing and device, and separating method

A separation element and separation unit technology, applied in separation methods, chemical instruments and methods, and degassing by filtering liquids, etc., can solve problems such as reducing possibility and short residence time, and achieve the effect of promoting buoyancy and increasing residence time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

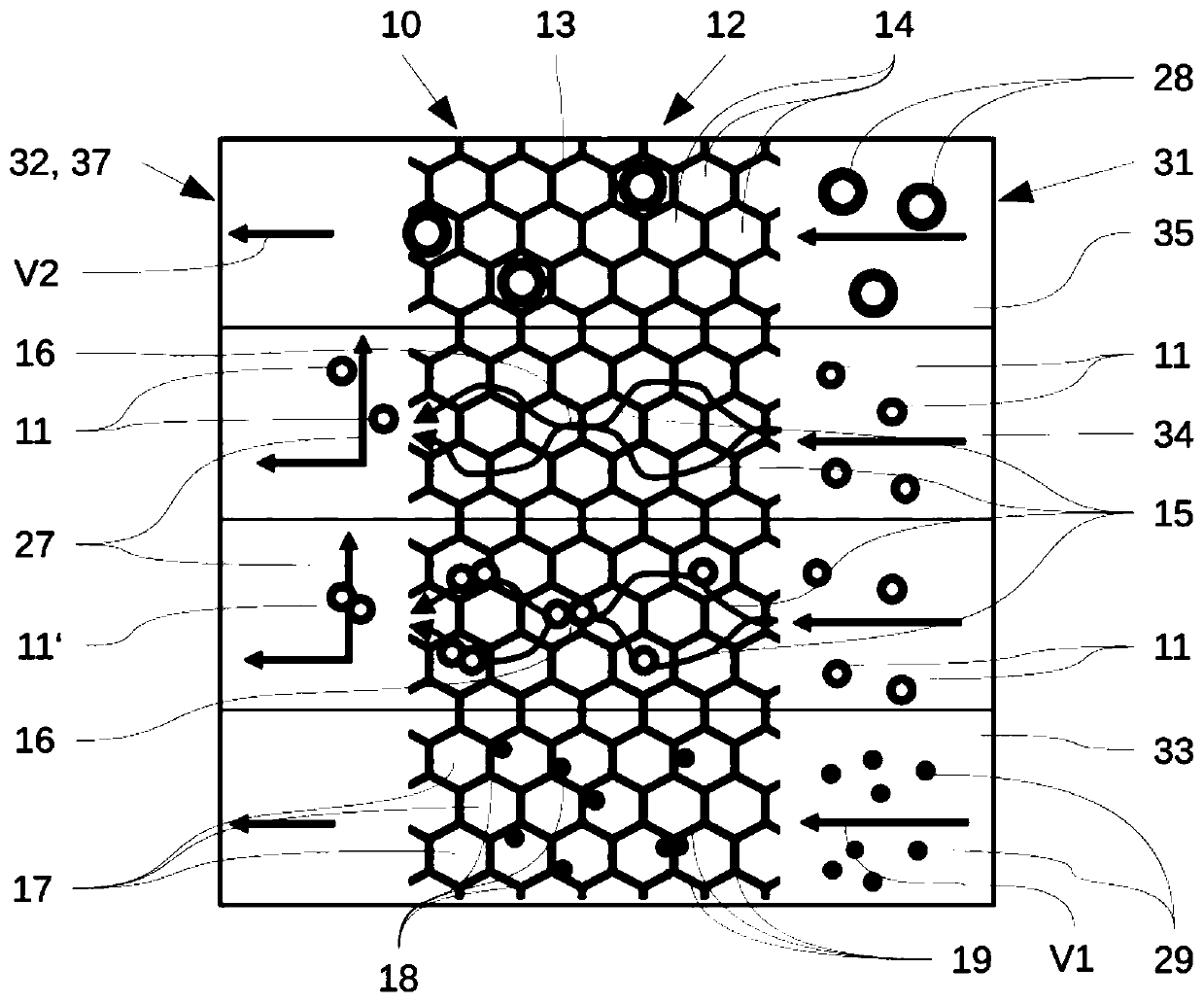

[0076] figure 1 A schematic diagram of a separation element 10 according to an exemplary embodiment of the invention is shown during the separation of gas bubbles of different sizes present in a liquid. The separating element 10 is used to separate air bubbles from liquids such as hydraulic oil, lubricating oil, engine oil, etc. In the following description, the liquid is generally referred to as oil, and the air bubbles are generally referred to as air bubbles.

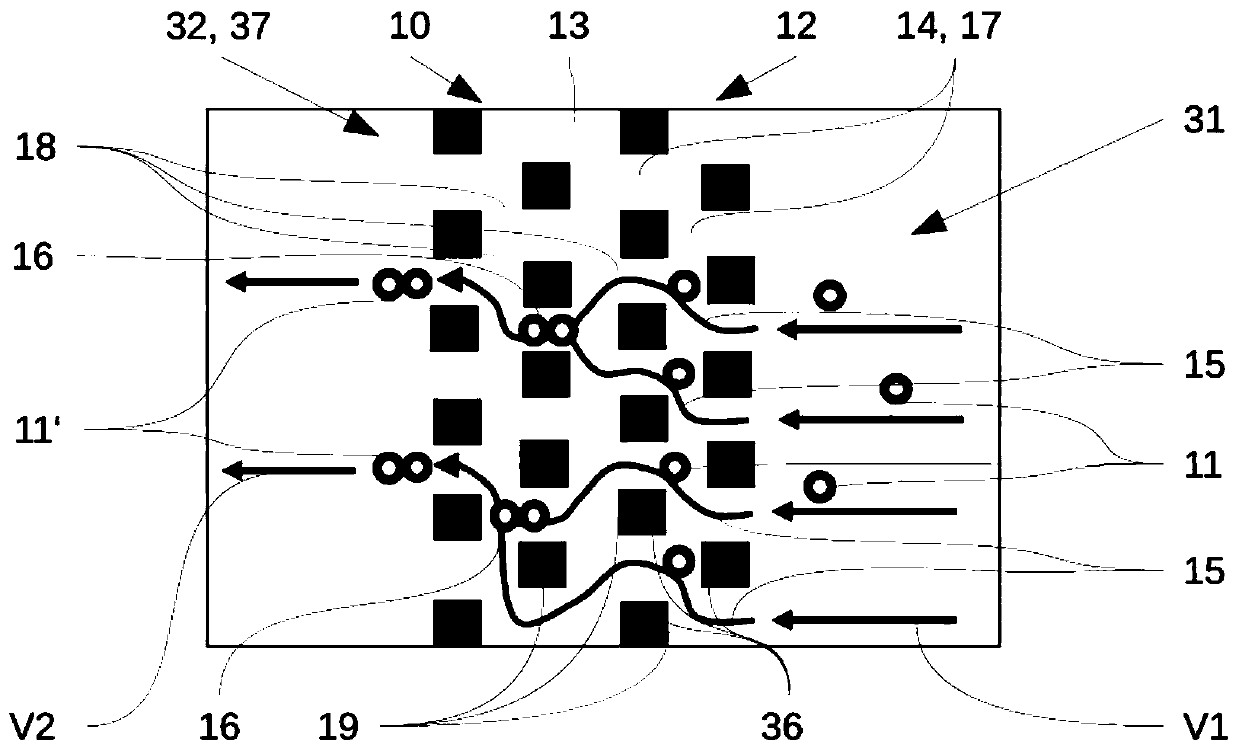

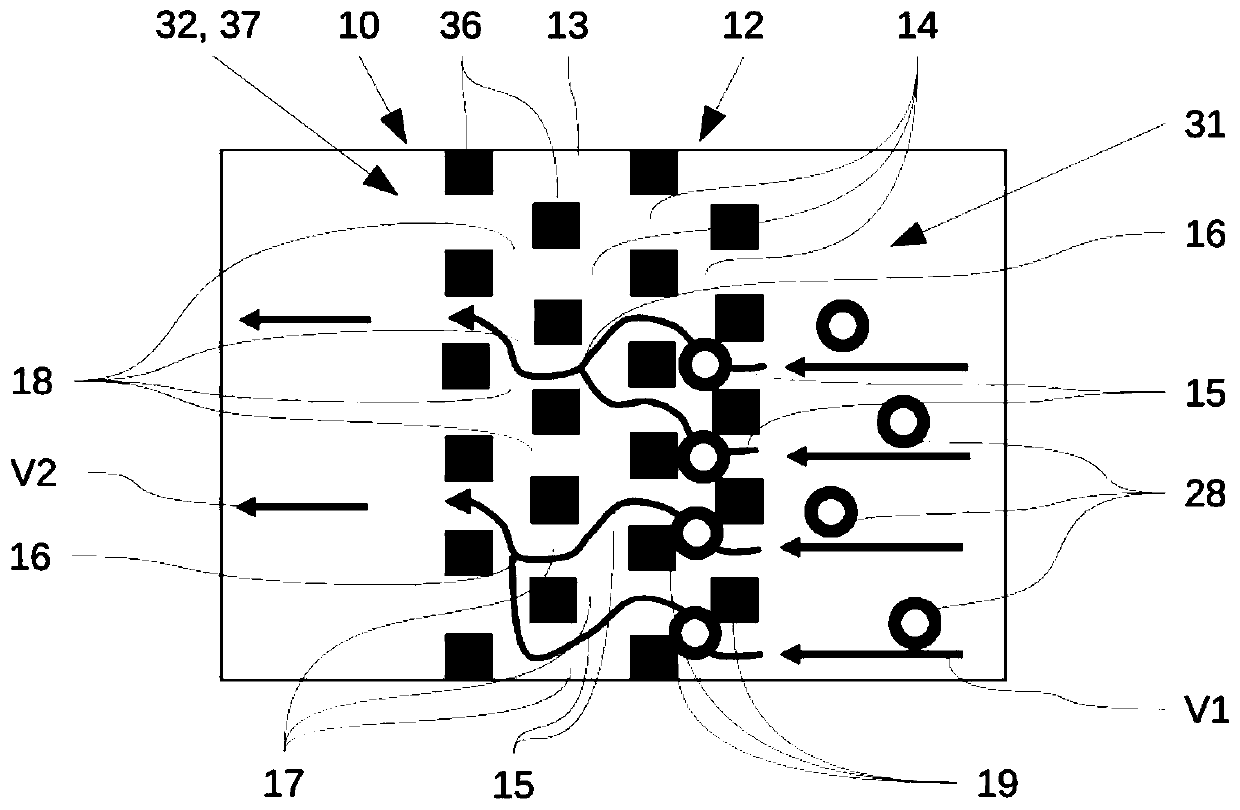

[0077] The separation element 10 is often used in combination with a filter device which, together with the tank, constitutes a tank filter system. This filter unit see Figure 5 with Figure 7 to Figure 10 , which will be discussed in detail later.

[0078] from figure 1 It can be seen that an approximately real air bubble distribution in a canister filter system of the type described above is displayed. Normally, when oil enters the tank, air bubbles separate from the oil. Said separating element 10 may be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com