Laboratory air tritium removal system

A laboratory and air technology, applied in gas treatment, vapor condensation, dispersed particle filtration, etc., can solve problems affecting the health of occupational workers, public and environmental impact, economic and property losses, etc., to avoid catalyst failure, reduce Scope of Tritium Leakage, Effect of Ensuring Public Safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

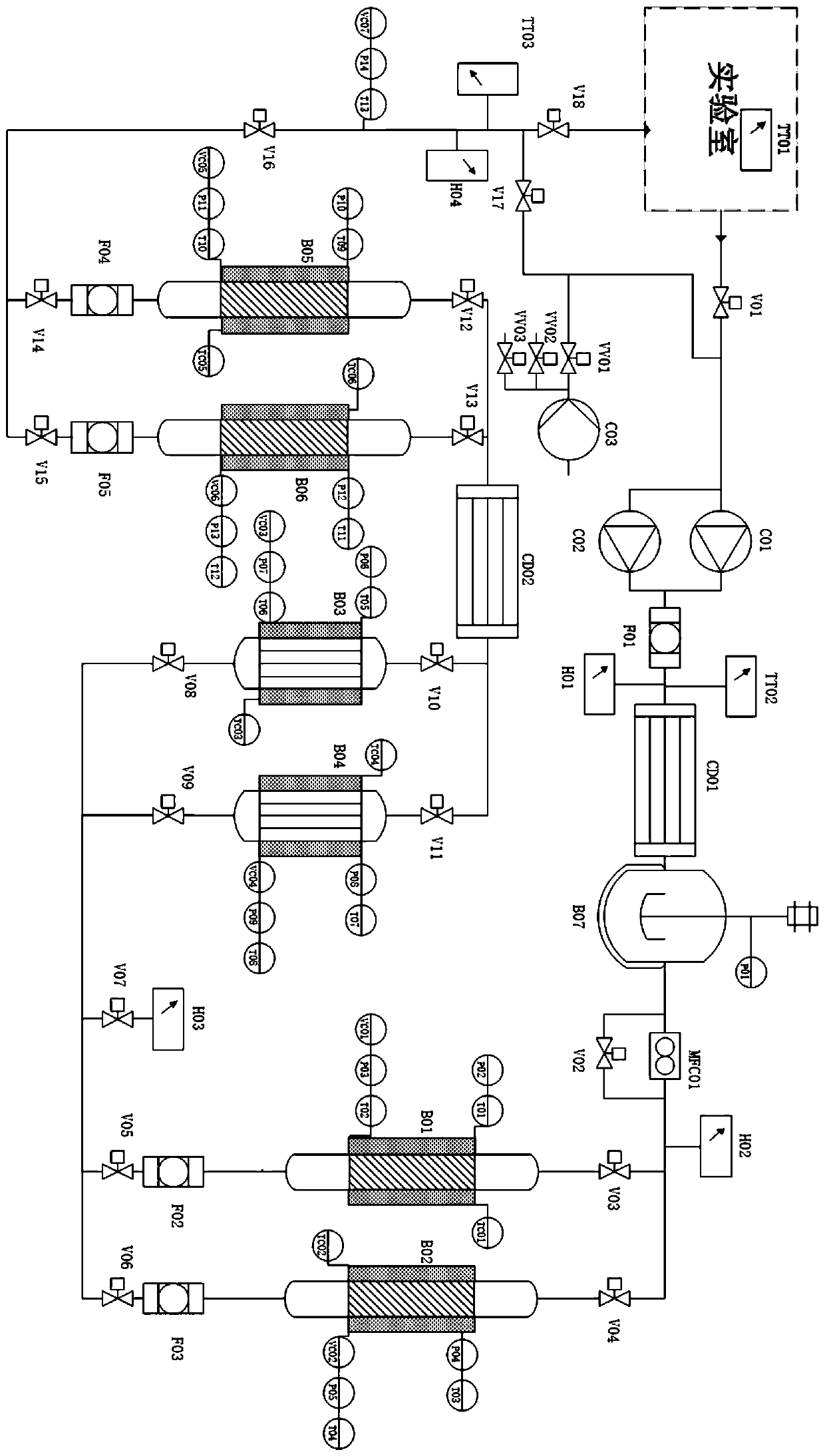

[0028] like figure 1 As shown, the laboratory air tritium removal system of the present invention includes a sealable laboratory, and also includes a tritium leakage monitoring system for monitoring the tritium content inside the sealable laboratory, blowers C01-C02, and air detritium removal for treating tritium-containing air system, the air inlet and outlet of the air detritium system are connected to the inside of the closed laboratory, and the air detritium system also includes a filter F01, a cold dryer CD01, Drying beds B01-B02, catalytic oxidation beds B03-B04, condenser CD02, adsorption beds B05-B06, the signal of the tritium leakage monitoring system is connected to the control system of the fan and the closed door of the laboratory, and the tritium leakage monitoring system includes tritium Analyzer TT01~TT03.

[0029] Use process: first of all, ensure that the valve, flow meter, frequency conversion fan, and vacuum pump are closed, and open the air supply system o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com