Multi-grade separation ore sand screening equipment for building materials

A technology for screening equipment and building materials, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of occupying a large area, inconvenient handling, low sand and gravel output, etc., to enhance the screening effect and prolong the screening time , the effect of reducing the floor area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

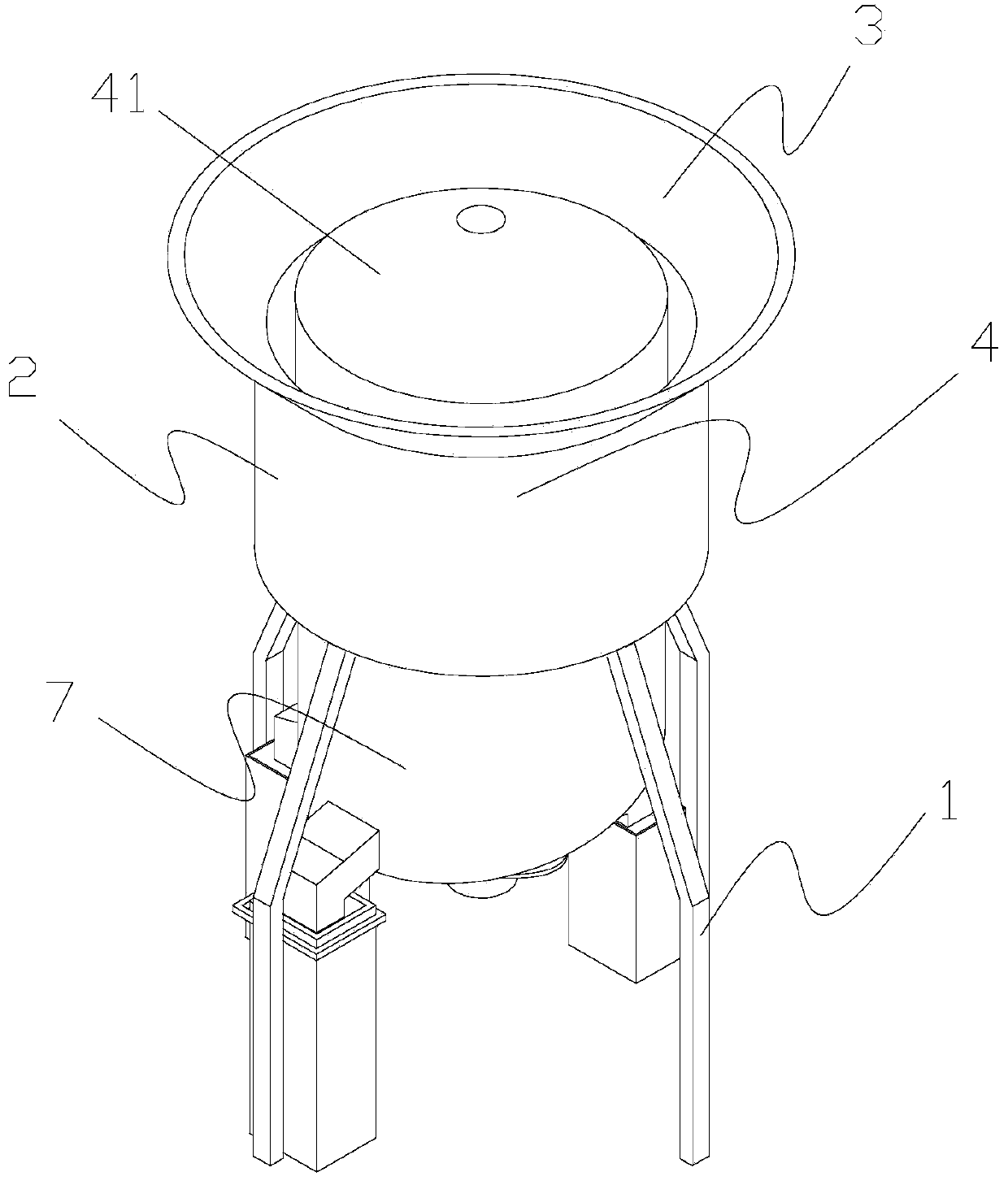

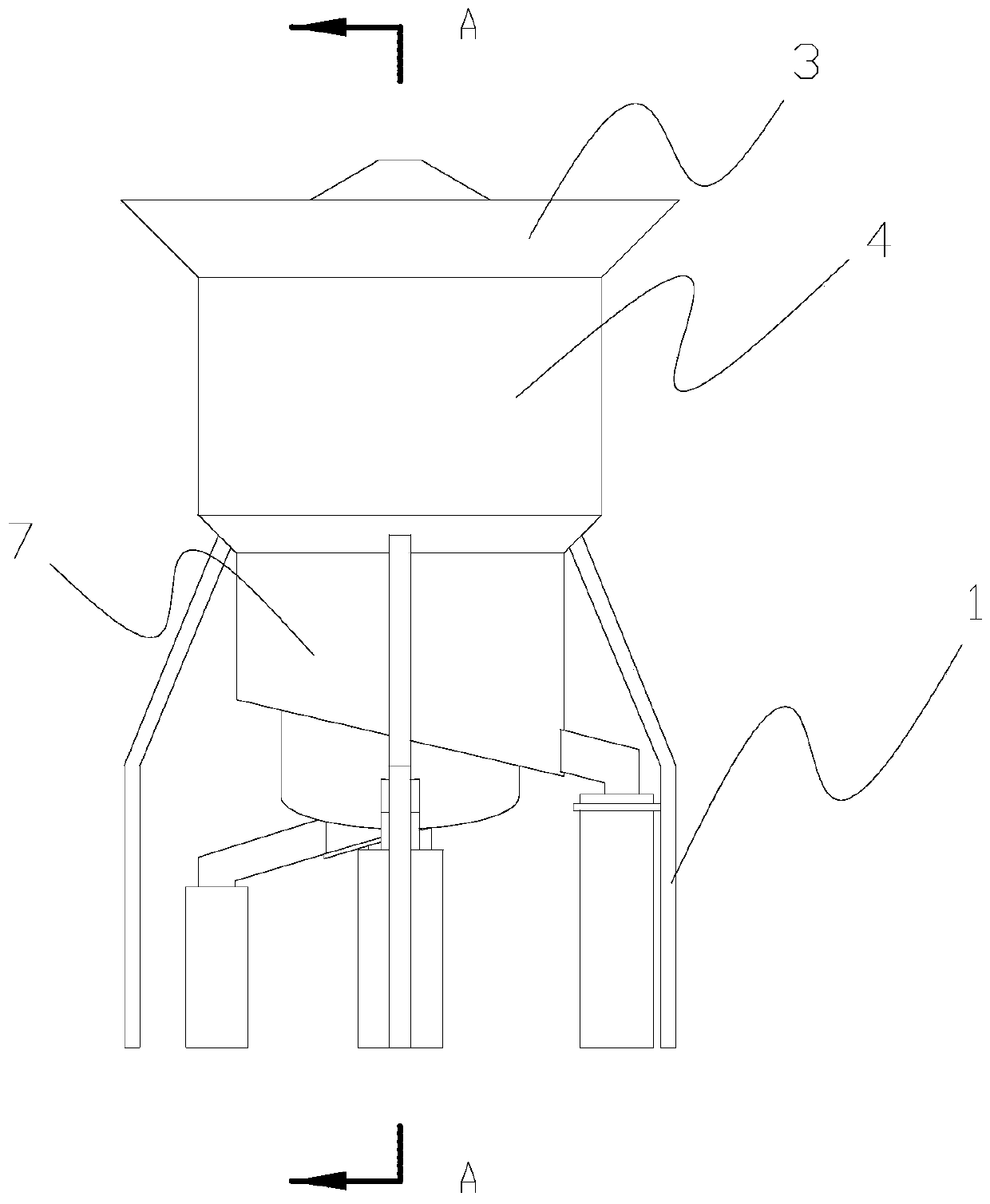

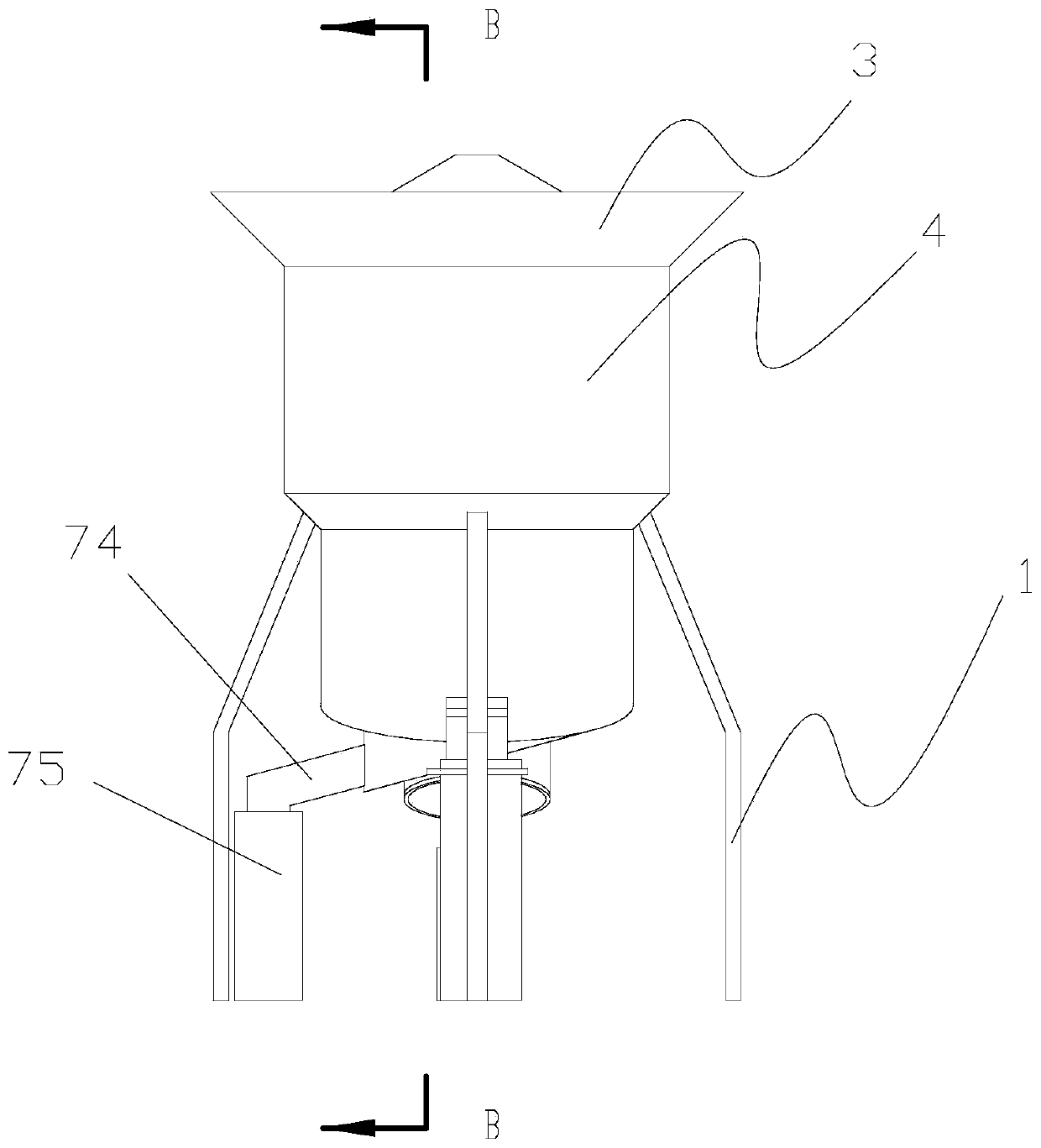

[0028] like Figure 1-13 As shown, a kind of ore screening equipment for multi-grade separation of building materials includes a bracket 1, a first casing 2, a material guide plate 3, and a screening device 4; the bracket 1 is placed on the ground, and the first casing 2 is located on the ground. On the bracket, the material guide plate 3 is arranged on the first casing, and the screening device 4 is arranged in the first casing; the bracket is provided with 4 pieces evenly arranged around the first casing and supported on the ground, and the first The housing is a structure with an inclined plane at the bottom, and the material guide plate is arranged on the top of the first housing, which is an inclined plane for guiding materials; the screening device 4 includes a second housing 41, a connecting block 42, an inlet Material opening 43, stepped screening structure 5, transmission structure 6, discharge structure 7; the second housing 41 is located in the first housing, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com