Feeding device for rotary table of electromachining lathe

A power feeding device and electric machining technology, applied in electric machining equipment, accessory devices, metal machining equipment, etc., can solve the problems of bloated conductive structure and poor contact of carbon brushes, so as to avoid bloated machine, reduce inconvenience, and avoid feeding. Low power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

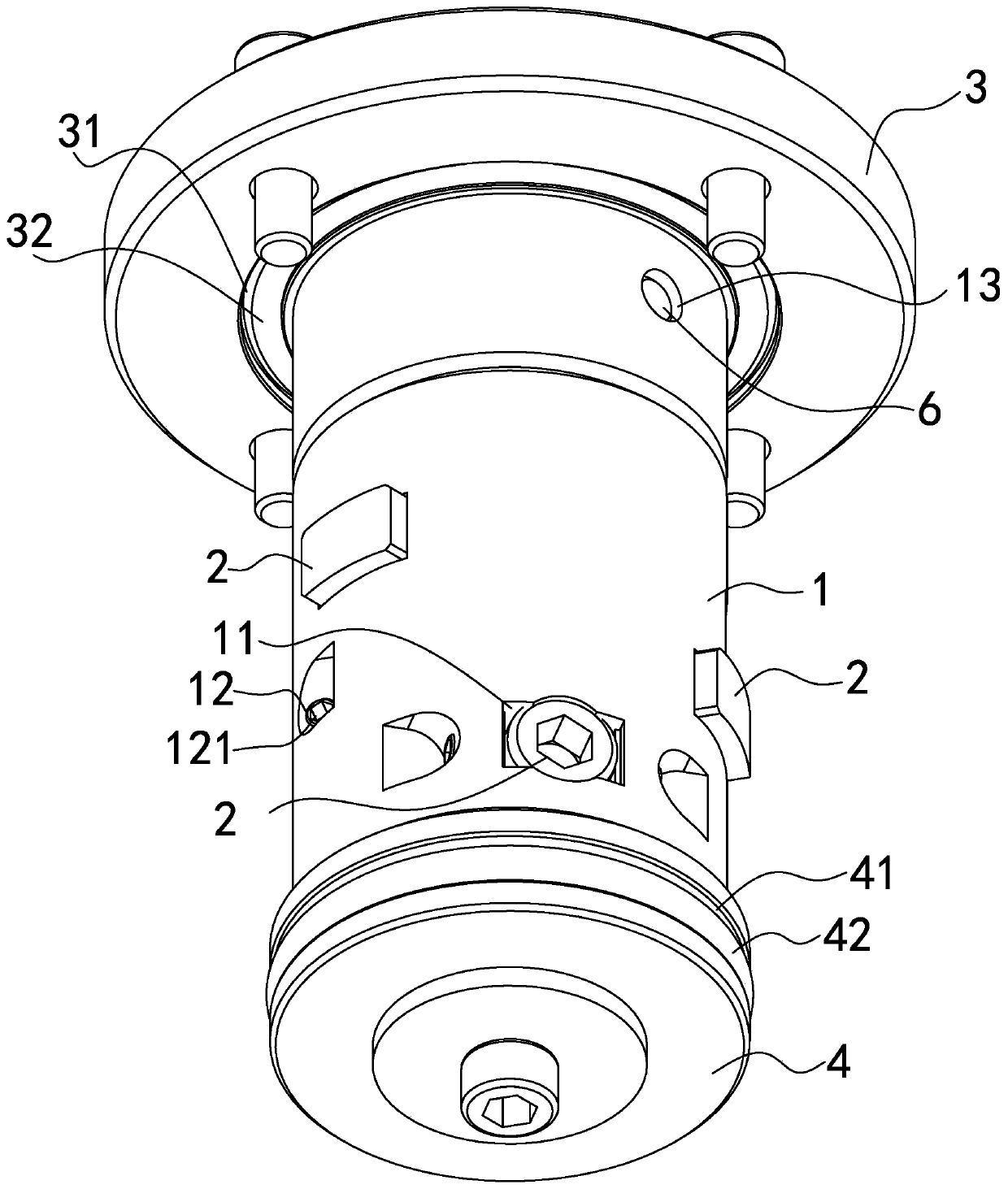

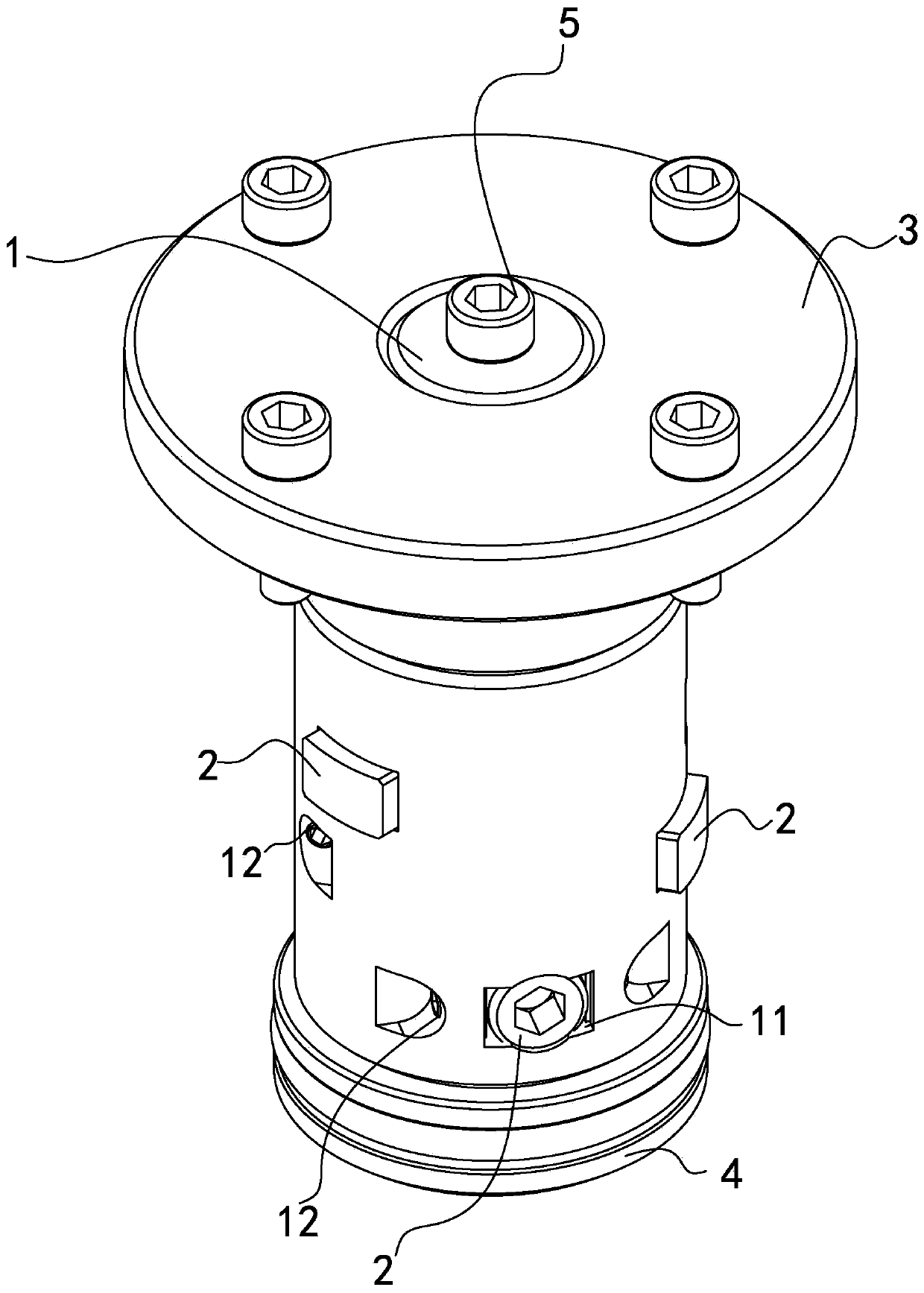

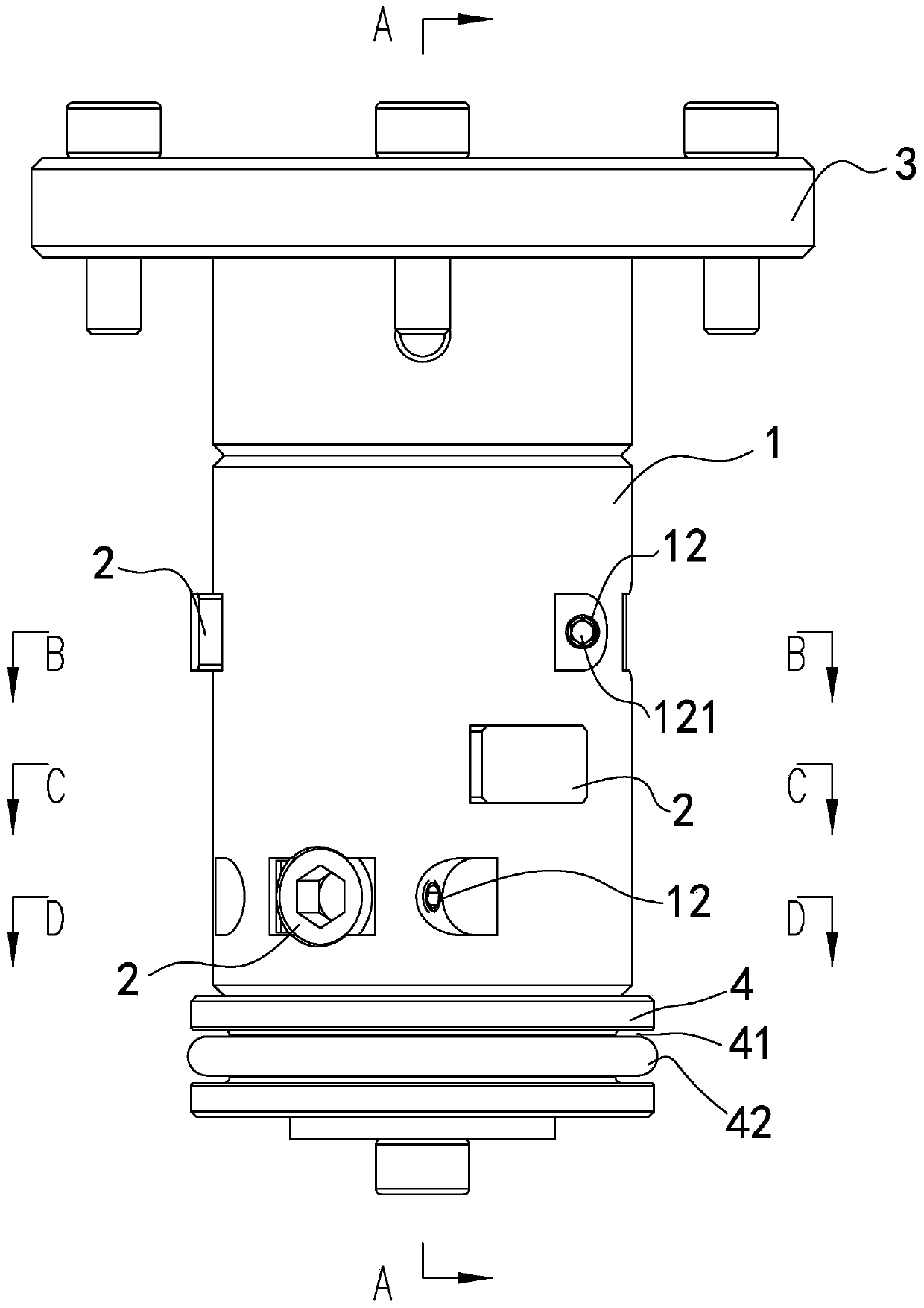

[0055] Such as Figure 1 to Figure 15 As shown, the embodiment of the present invention provides a power feed device for the turntable of an electric machine tool, which is used to feed the rotating turntable spindle 7, and the carbon brush shaft 1 is installed in the center hole of the turntable spindle 7 and connected to the The turntable main shaft 7 is sealed and connected, the bottom of the carbon brush shaft 1 is provided with a liquid-proof ring 4, the upper end of the carbon brush shaft 1 is fixedly connected with the insulating gland 3, and the upper end of the carbon brush shaft 1 After passing through the insulating gland 3, a power feeder 5 is connected. The carbon brush shaft 1 is located in the installation space formed by the insulating gland 3, the liquid-proof ring 4 and the turntable spindle 7. The carbon brush The shaft 1 and the turntable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com