Support part clamp

A technology of parts and fixtures, which is applied in the field of mechanical processing, can solve the problems of high manufacturing cost and storage cost of assembly fixtures, unstable assembly quality of assembly fixtures, and high labor intensity for workers to install and disassemble, so as to reduce labor intensity and simple structure , the effect of quick replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, so as to help those skilled in the art have a more complete and in-depth understanding of the present invention.

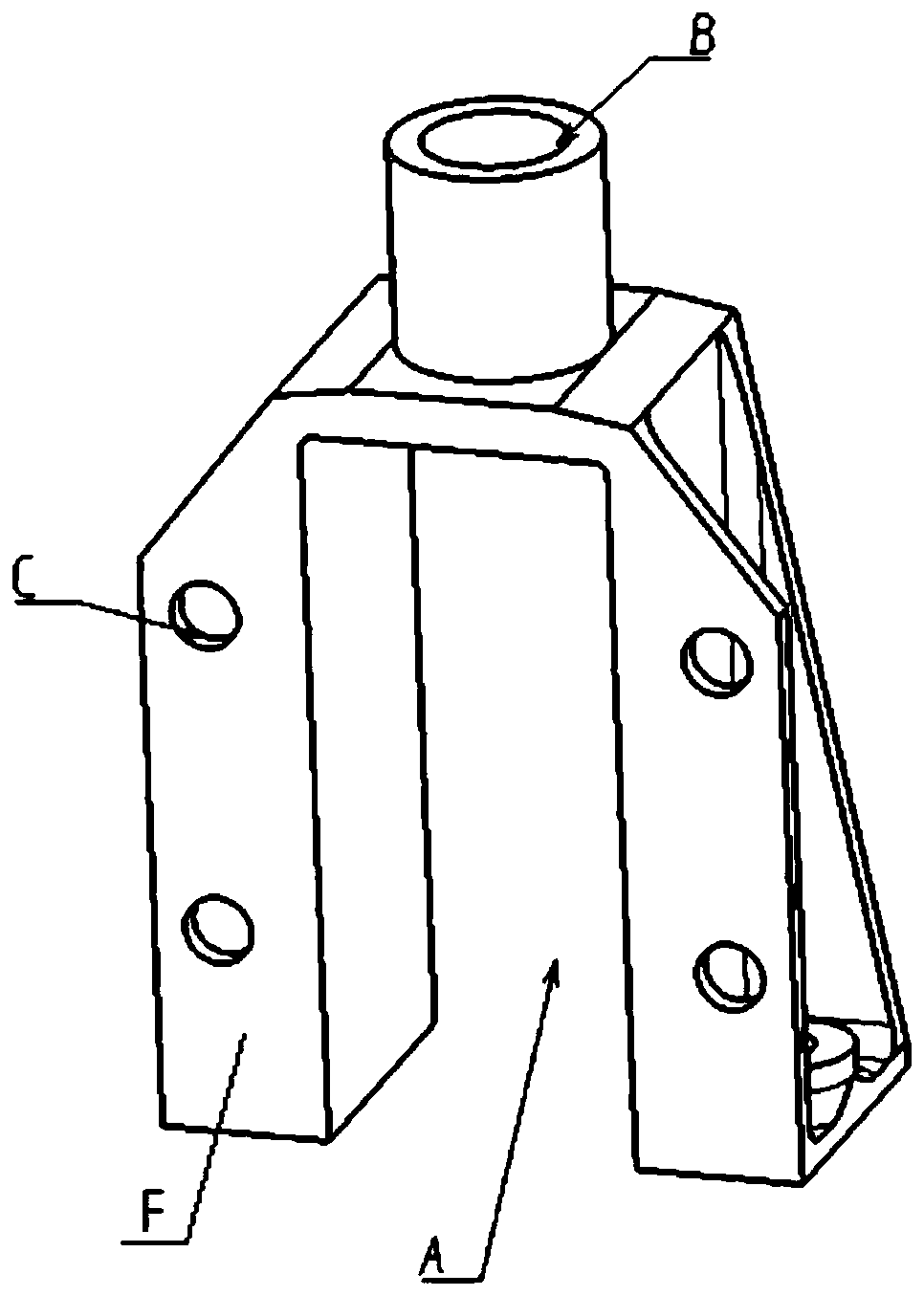

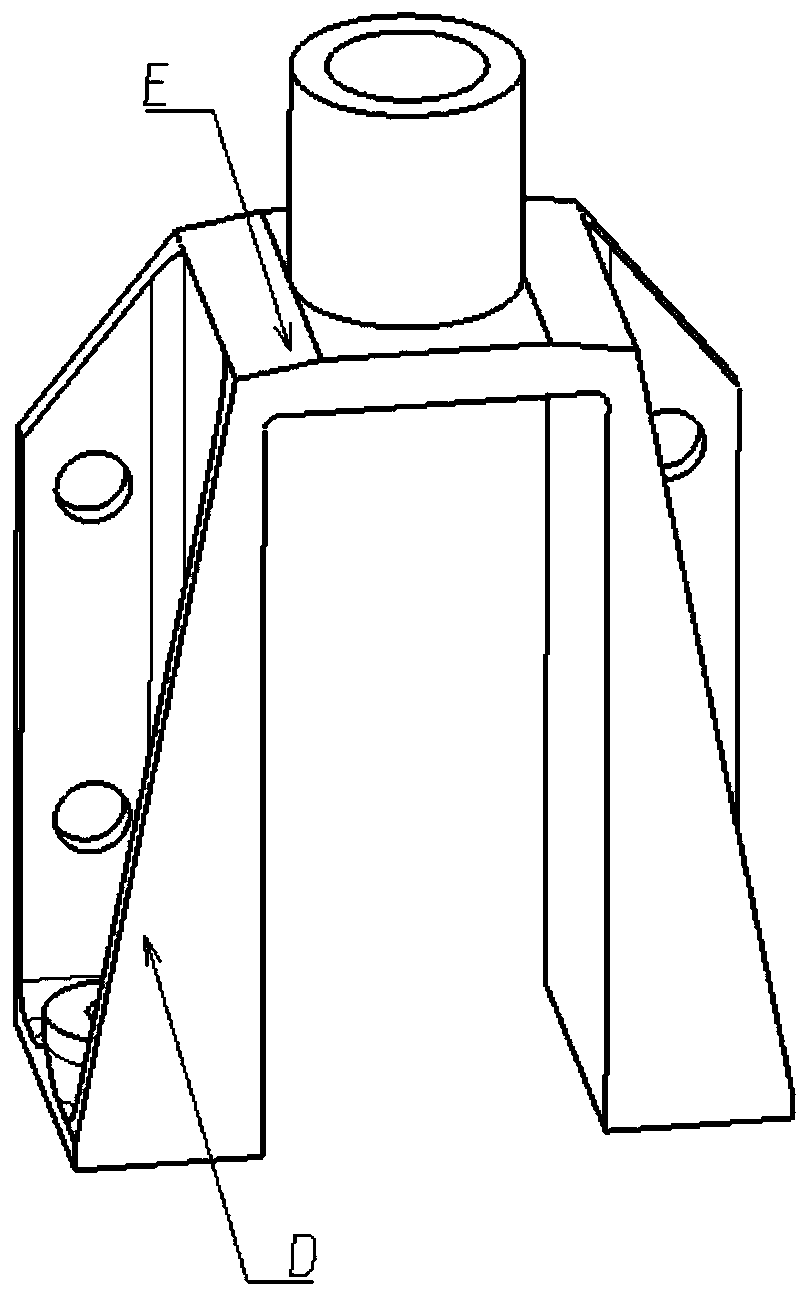

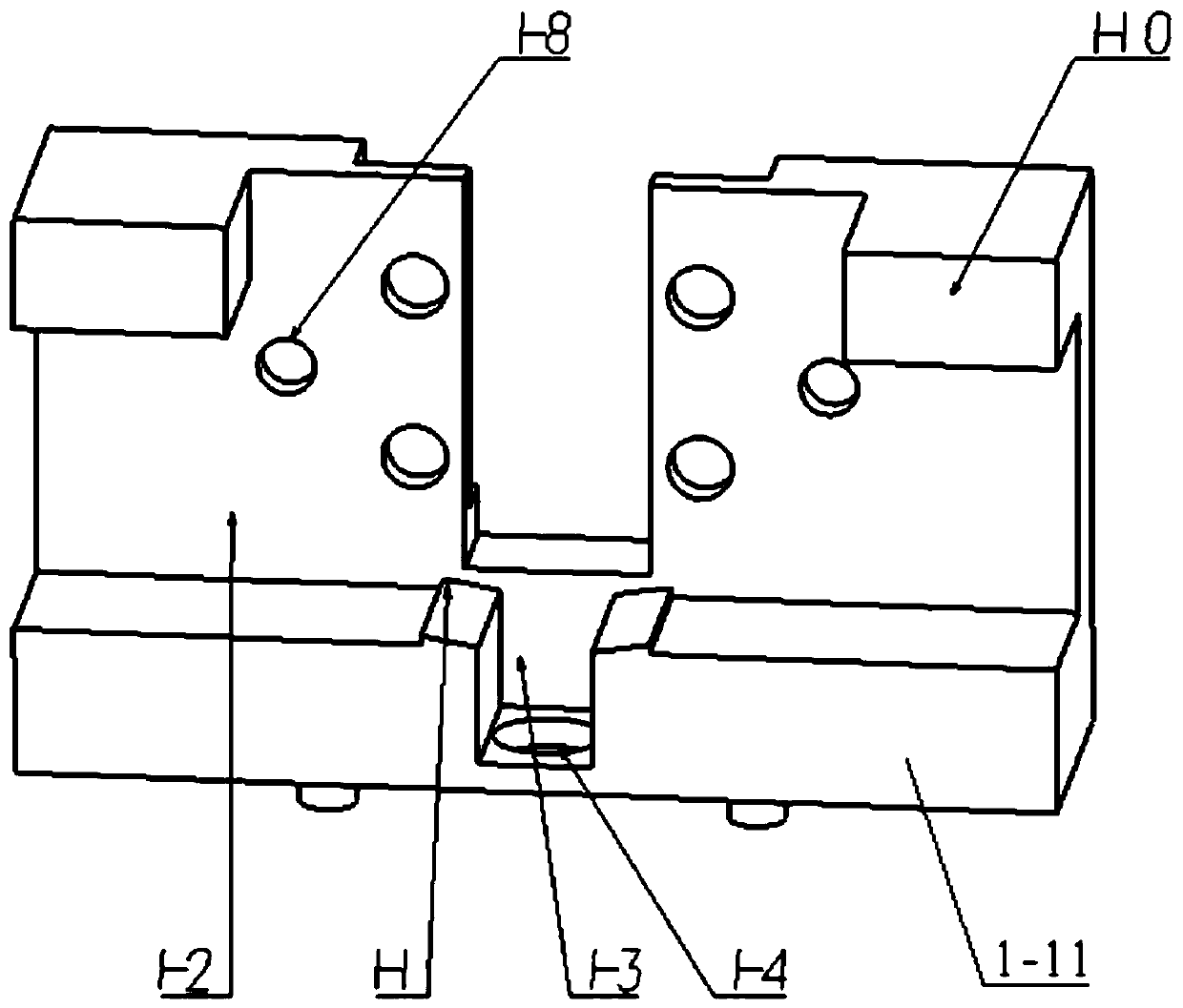

[0024] like Figure 3-Figure 6 As shown, a bracket part fixture includes a base body 1, a large drill sleeve 2, a small drill sleeve 3, a stud 4, a pressure plate 5 and a lock nut 6.

[0025] The bottom of the base 1 is provided with four pillars 1-9, and the top of the base 1 is provided with a boss B1-10. Boss A1-11 and surface A1-2 are processed on the lower part of base body 1 . The center of the boss A1-11 is processed with a V-shaped positioning surface 1-1; the bracket part to be processed is put into the base body 1, the surface F of the part to be processed is attached to the surface A1-2 of the base body, and the part to be processed is The surface E cooperates with the V-shaped positioning surface 1-1 to rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com