A kind of preparation method of natural latex tube

A technology for natural latex and latex tubes, applied in the field of natural latex tubes, can solve the problems of reduced production efficiency of thermal extrusion method, increased appearance quality defects, difficulty in meeting market demands, etc., and achieves good diameter consistency and improved tensile strength. , the effect of increasing the constant elongation value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

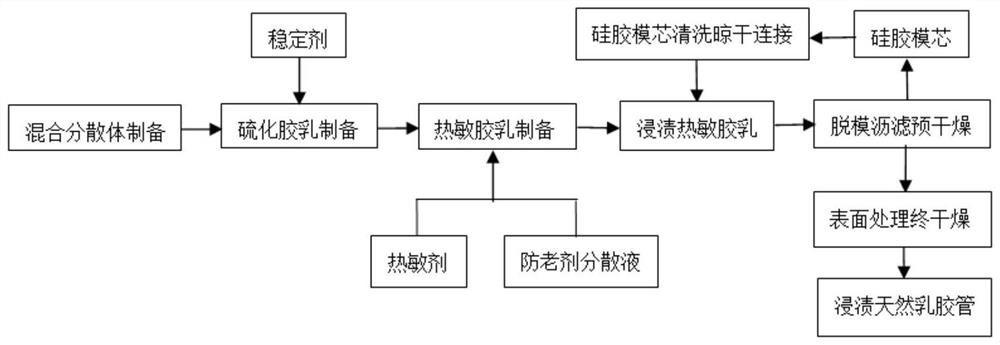

Method used

Image

Examples

Embodiment 1

[0063] Preparation of large-scale natural latex tubes of 6 mm × 13 mm by cyclic dipping method

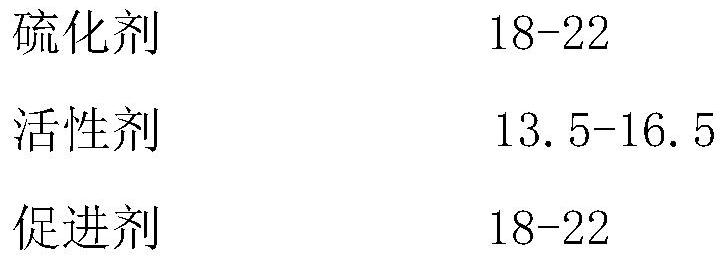

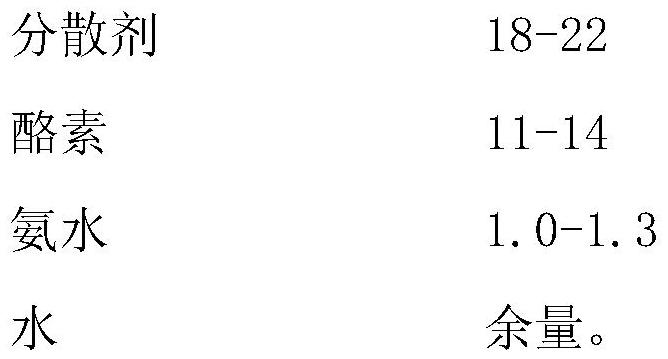

[0064] Step 1: prepare the mixed dispersion that solid content is 50wt% by following weight ratio:

[0065]

[0066] The above materials were put into a ball mill with a rotating speed of 80rpm to grind for 60h, and filtered with a stainless steel screen with a pore size of 0.28mm.

[0067] Step 2: prepare the vulcanized latex that solid content is 55wt% by following weight ratio:

[0068]

[0069]

[0070] Stir the concentrated latex in the latex vulcanization tank and add the stabilizer, pass hot water into the interlayer of the latex vulcanization tank to raise the temperature of the latex to 40°C, then add 45wt% MG49 Tianjia latex, 28wt% epoxidized natural latex and 50wt% aqueous calcium carbonate The mixture, 50wt% mixed dispersion and water were heated to 55°C and then kept warm for 88 minutes. After the chloroform value of the vulcanized latex reached the end, it w...

Embodiment 2

[0081] Preparation of large-scale natural latex tubes of 7 mm × 15 mm by cyclic dipping method

[0082] Step 1: prepare the mixed dispersion that solid content is 50wt% by following weight ratio:

[0083]

[0084] The above materials were put into a ball mill with a rotating speed of 80rpm to grind for 60h, and filtered with a stainless steel screen with a pore size of 0.28mm.

[0085] Step 2: prepare the vulcanized latex that solid content is 55wt% by following weight ratio:

[0086]

[0087] Stir the concentrated latex in the latex vulcanization tank and add the stabilizer, pass hot water into the interlayer of the latex vulcanization tank to raise the temperature of the latex to 40°C, then add 45wt% MG49 Tianjia latex, 28wt% epoxidized natural latex and 50wt% aqueous calcium carbonate The mixture, 50wt% mixed dispersion and water were heated to 56°C and kept warm for 83 minutes. After the chloroform value of the vulcanized latex reached the end, it was cooled to room...

Embodiment 3

[0098] Preparation of large-scale natural latex tubes of 7 mm × 16 mm by cyclic dipping method

[0099] Step 1: prepare the mixed dispersion that solid content is 50wt% by following weight ratio:

[0100]

[0101] The above materials were put into a ball mill with a rotating speed of 80rpm to grind for 60h, and filtered with a stainless steel screen with a pore size of 0.28mm.

[0102] Step 2: prepare the vulcanized latex that solid content is 55wt% by following weight ratio:

[0103]

[0104]

[0105] Stir the concentrated latex in the latex vulcanization tank and add stabilizer, pass hot water into the interlayer of the latex vulcanization tank to raise the temperature of the latex to 38°C, then add 45wt% MG49 Tianjia latex, 28wt% epoxidized natural latex and 50wt% aqueous calcium carbonate The mixture, 50wt% mixed dispersion and water were heated to 57°C and kept warm for 79 minutes. After the chloroform value of the vulcanized latex reached tertiary, it was coole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com