Turnover support assembly structure and assembling method thereof

A technology of overturning bracket and assembly structure, applied in the field of overturning bracket, which can solve problems such as difficult to tighten connecting bolts, and achieve the effect of high assembly efficiency and easy tightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

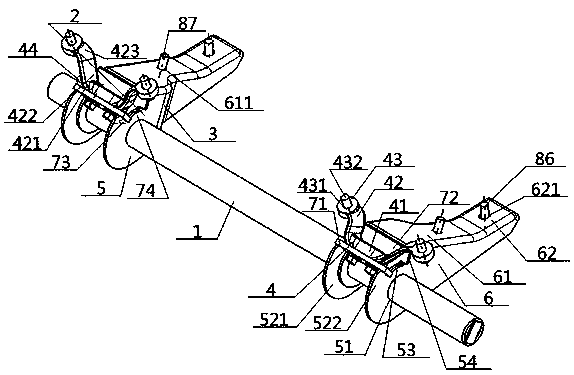

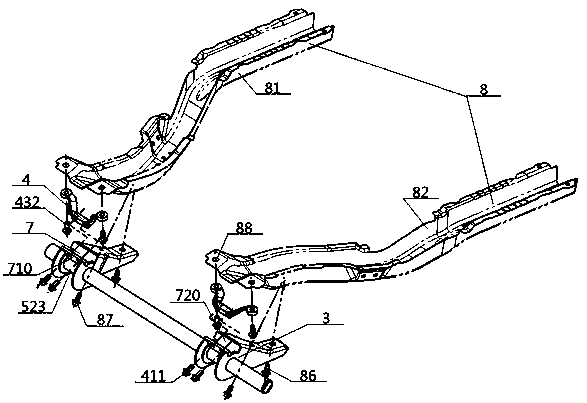

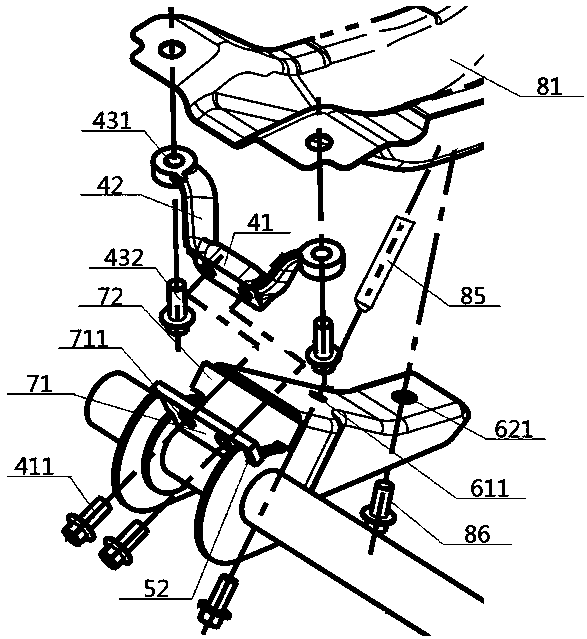

[0049] see figure 1 — Figure 5 , an overturn bracket assembly structure, including an overturn shaft 1 and overturn brackets 2 respectively sheathed at both ends thereof; part 5 and the inner connection part 6, the middle part of the outer connection part 5 is provided with a shaft passing hole 51 for the turning shaft 1 to pass through, and the right side part of the outer connection part 5 is connected to the left side part of the inner connection part 6 connection, the top surface of the inner connection part 6 is connected with the cab 8, and the top of the outer connection part 5 is provided with a concave snap-in mechanism 7, the snap-fit mechanism 7 includes a No. 1 slope 710 and a No. 2 slope 720. The distance between the top of the slope 710 and the second slope 720 is greater than the distance between the bottom; the upper connector 4 includes connecting the middle plate 41 and connecting wing plates 42 connected to its two ends, the middle part of the connection...

Embodiment 2

[0052] Basic content is the same as embodiment 1, the difference is:

[0053] The No. 1 slope 710 is the No. 1 slope 71, and the No. 2 slope 720 is the No. 2 slope 72. The bottom ends of the No. 1 slope 71 and the No. 2 slope 72 are connected to the top of the external connection part 5. The top of the slanted plate 71 extends upwards towards the direction away from the internal connection portion 6, the top end of the second slanted plate 72 extends upwards towards the direction close to the internal connection portion 6, and the distance between the tops of the first slanted plate 71 and the second slanted plate 72 is Greater than the distance between the bottoms, the included angles 73 between the bottoms of the No. 1 slanted plate 71 and the No. 2 slanted plate 72 and the horizontal plane are all acute angles. Preferably, a space 74 between the bottoms of the No. 1 slanted plate 71 and the bottoms of the No. 2 slanted plate 72 is interposed.

Embodiment 3

[0055] Basic content is the same as embodiment 1, the difference is:

[0056] The connection between the upper connector 4 and the bottom 81 of the No. 1 chamber and the bottom 82 of the No. 2 chamber refers to the interconnection of the wing connecting holes 431 and the wing connecting bolts 432;

[0057] The falling of the cab unit to the external connection part 5 means: the bottom 81 of the first room and the bottom 82 of the second room are provided with a room positioning pin hole 83 and a room fixing hole 84, and the top surface of the inner connection part 6 is provided with a bottom Locating pin hole 611 and following fixed connection hole 621, during operation, insert an end that has locating pin 85 in chamber locating pin hole 83 earlier, insert the other end of locating pin 85 down locating pin hole 611 when falling again, to complete whereabouts;

[0058]The fixed connection between the upper connecting piece 4 and the corresponding clamping mechanism 7 refers to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com