Automatic unstacker

A depalletizer and automatic technology, which is applied in the directions of packaging, cutting and unsealing, transportation and packaging, etc., can solve the problems of complex structure and low efficiency, and achieve the effect of reducing manpower operation, improving service life and reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

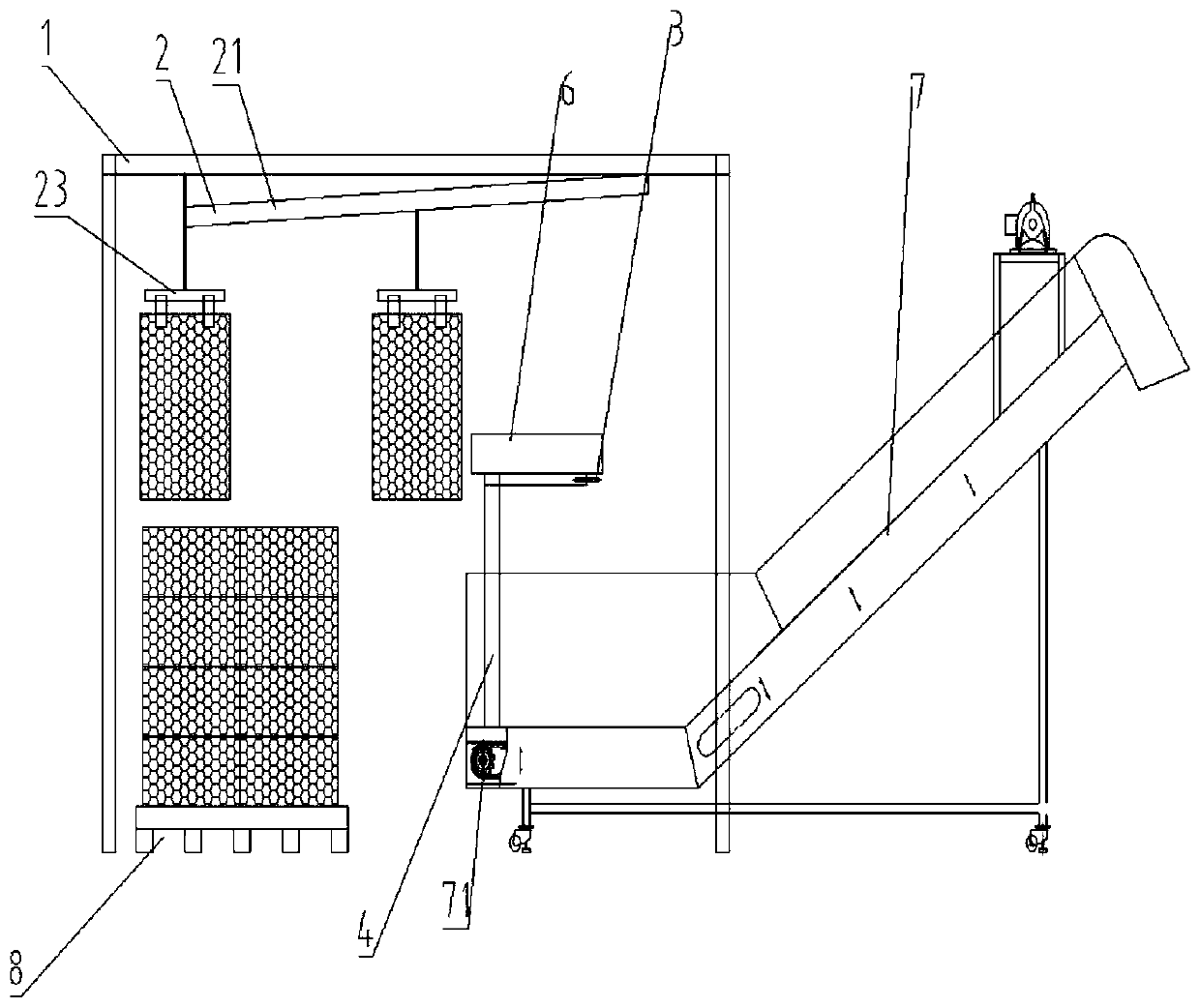

[0036]An automatic depalletizing machine, comprising a casing 1, a transport mechanism 2, an unpacking mechanism 3, a bracket 4, a dust removal mechanism 5, an automatic bag conveying mechanism 6, a discharge mechanism 7, and an automatic lifting platform 8, and the transport mechanism 2 includes a circular guide rail 21 With the motor 22 and three clamping devices 23, the motor 22 drives the clamping device 23 to move along the circular guide rail, the unpacking mechanism 3 includes a blade 31, and the discharging mechanism 7 includes a discharge conveyor belt 71, and the blade 31 is positioned above the discharge conveyor belt 71 . The level of the end of the ring guide rail 21 close to the blade 31 is higher than that of the end away from the blade 31, and the automatic lifting platform 8 is located below the lowest end of the ring guide rail. The bag opening mechanism 3 and the automatic pressing bag conveying mechanism 6 are fixedly connected on the support 4, the automat...

Embodiment 2

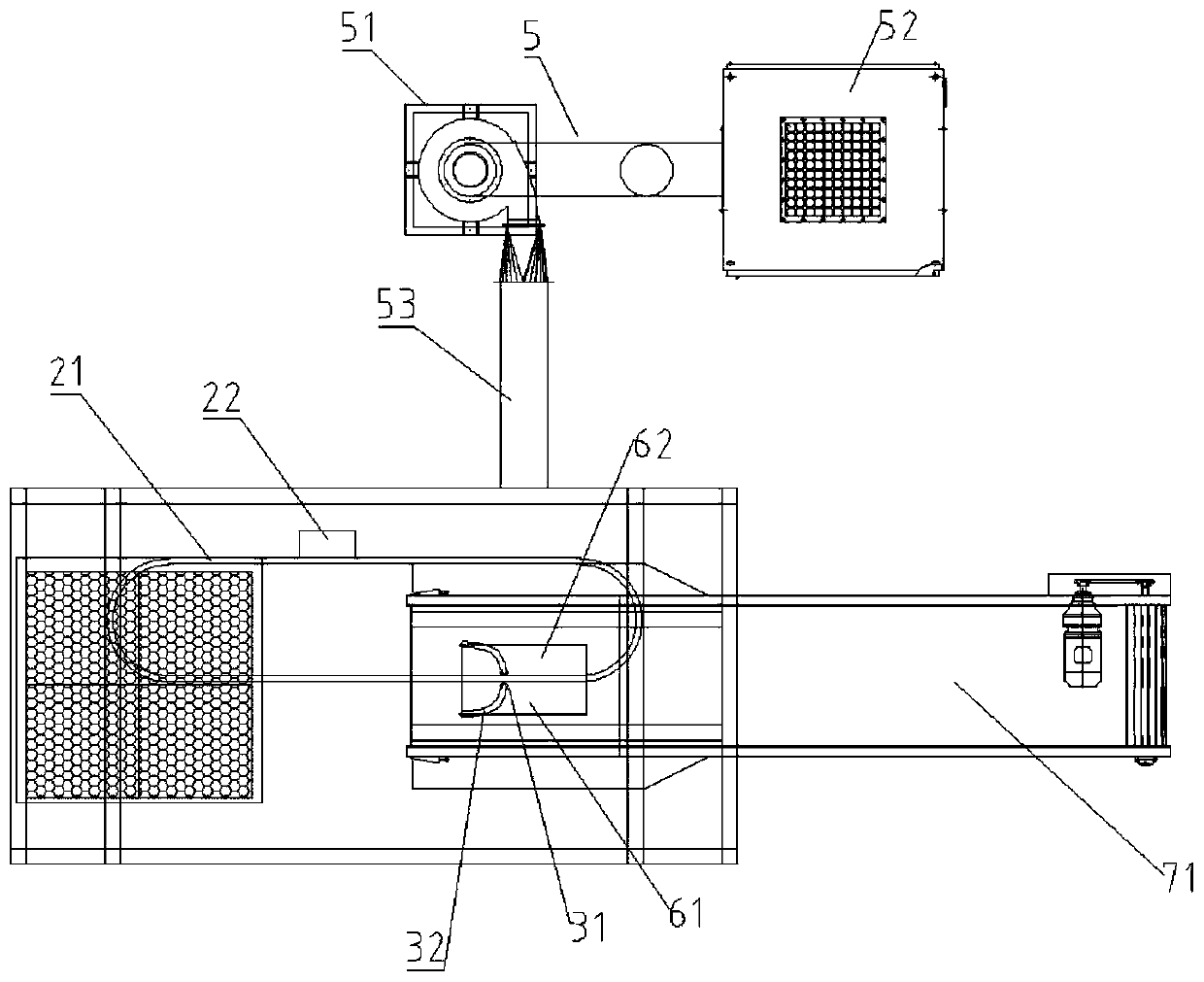

[0039] An automatic unstacking machine, comprising a casing 1, a transport mechanism 2, a bag opening mechanism 3, a bracket 4, an automatic bag conveying mechanism 6, a dust removal mechanism 5, a discharging mechanism 7 and an automatic lifting platform 8, and the transportation mechanism 2 includes a ring guide rail 21 and motor 22 and three clamping devices 23, the motor 22 drives the clamping device 23 to move along the circular guide rail, the unpacking mechanism 3 includes a blade 31, and the discharging mechanism 7 includes a discharge conveyor belt 71, and the blade 31 is positioned at the end of the discharge conveyor belt 71. above. The level of the end of the ring guide rail 21 close to the blade 31 is higher than that of the end away from the blade 31, and the automatic lifting platform 8 is located below the lowest end of the ring guide rail. The bag mechanism 3 and the automatic pressing bag conveying mechanism 6 are fixedly connected on the support 4, and the a...

Embodiment 3

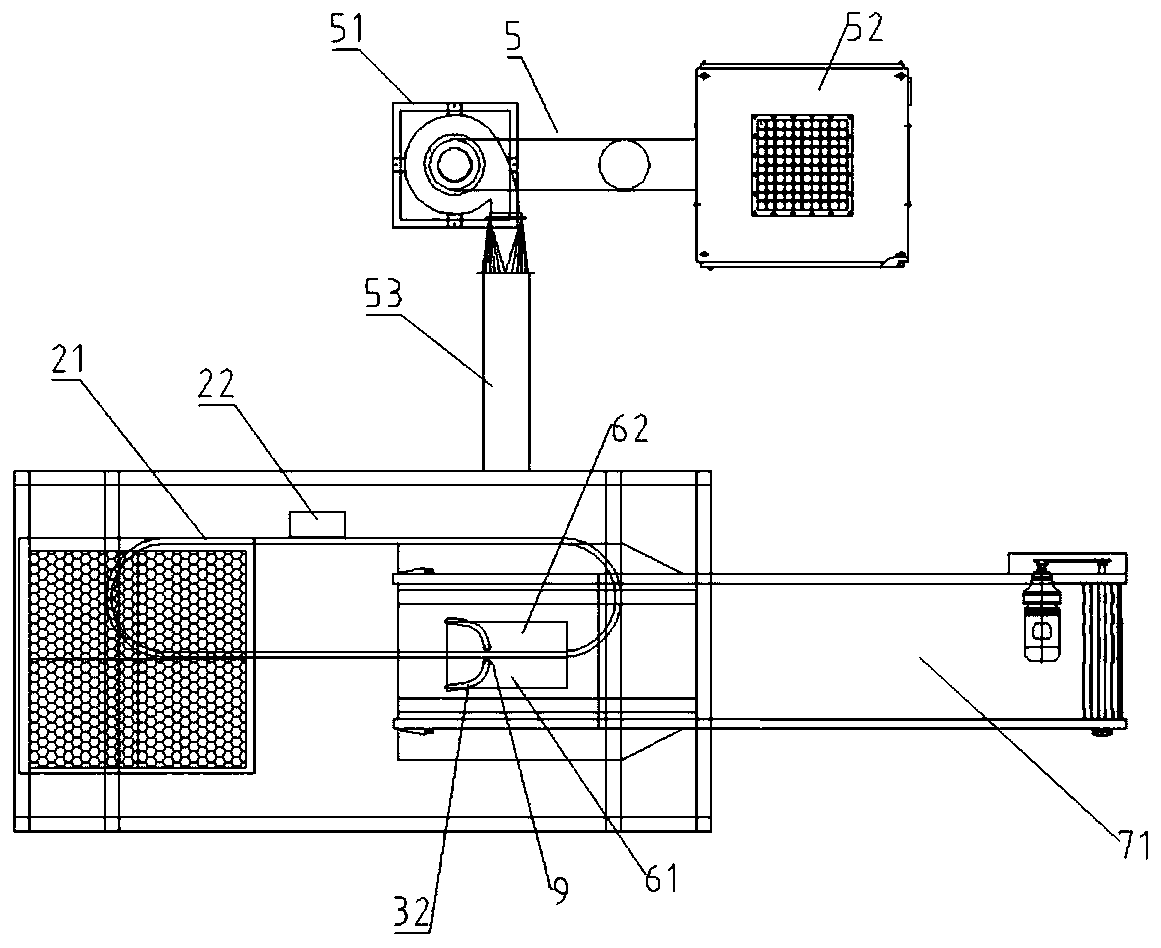

[0042] An automatic unstacking machine, comprising a casing 1, a transport mechanism 2, a bag opening mechanism 3, a bracket 4, an automatic bag conveying mechanism 6, a dust removal mechanism 5, a discharging mechanism 7 and an automatic lifting platform 8, and the transportation mechanism 2 includes a ring guide rail 21 and motor 22 and three clamping devices 23, the motor 22 drives the clamping device 23 to move along the circular guide rail, the unpacking mechanism 3 includes an electric knife 9, and the discharging mechanism 7 includes a discharge conveyor belt 71, and the electric knife 9 is located on the discharge conveyor belt 71 above. The level of the end of the ring guide rail 21 close to the electric knife 9 is higher than the end far away from the electric knife 9, and the automatic lifting platform 8 is located below the lowest end position of the ring guide rail. The bag mechanism 3 and the automatic pressing bag conveying mechanism 6 are fixedly connected on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com