Bidirectional unstacking and taking device and bidirectional cargo unstacking equipment

A two-way, goods-based technology, applied in the direction of object destacking, transportation and packaging, etc., can solve the problems of poor versatility, complex structure, high cost, etc., and achieve the effect of low cost, strong operability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

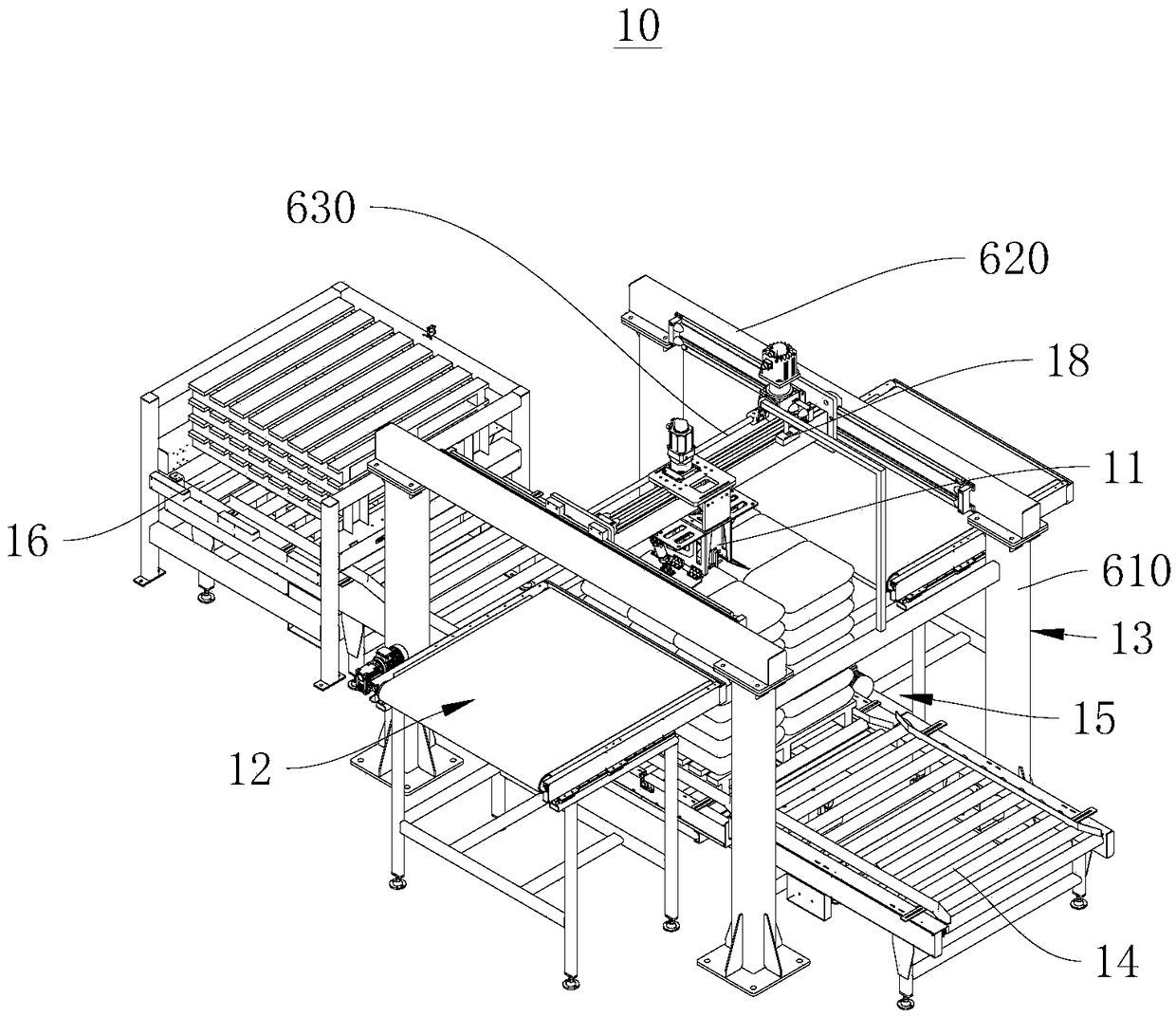

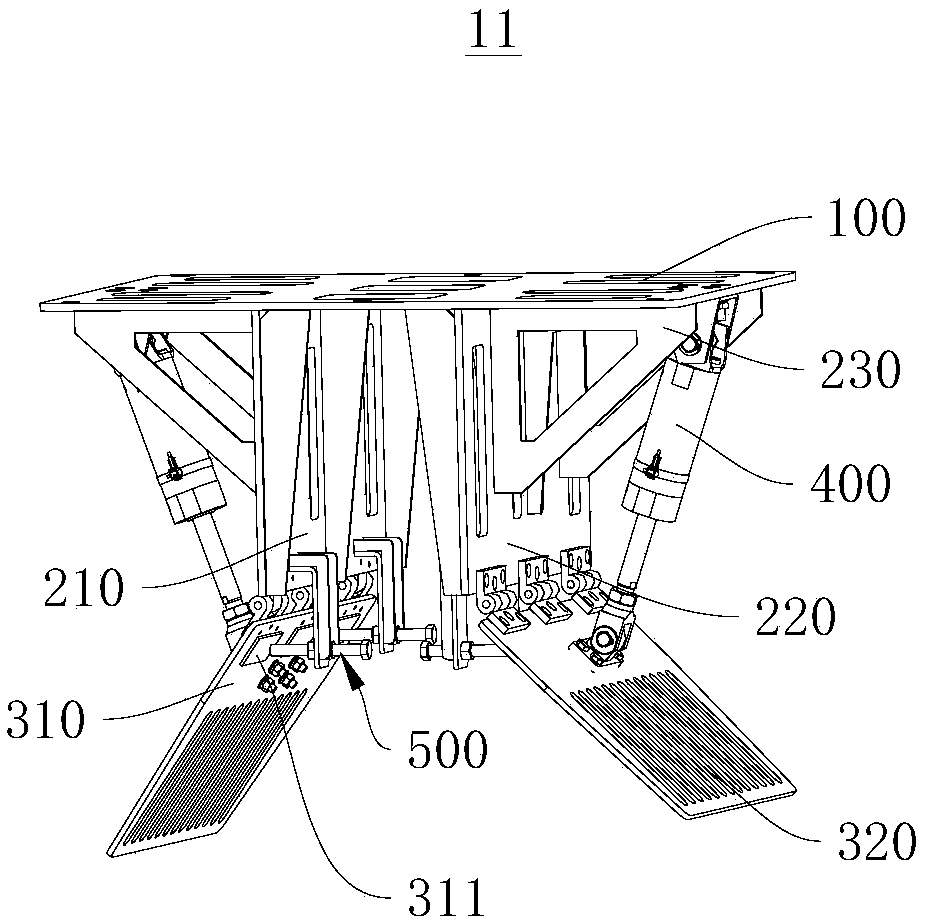

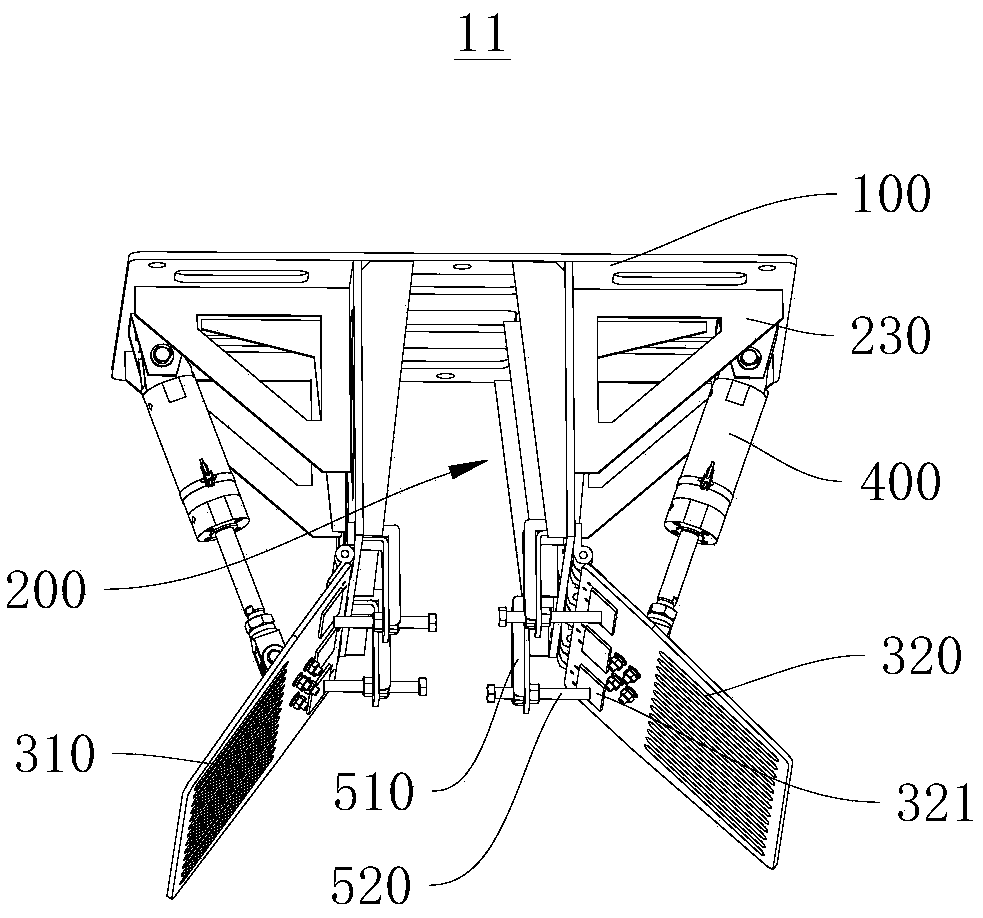

[0061] see figure 1 , the present embodiment provides a two-way cargo depalletizing device 10 . The two-way cargo depalletizing device 10 can improve the efficiency of cargo depalletizing. In addition, the two-way depalletizing device 11 adopted by the two-way cargo depalletizing device 10 has a simple structure, strong operability, and can improve the efficiency of cargo destacking.

[0062] It should be noted that, in this embodiment, the two-way cargo depalletizing equipment 10 is used to depalletize cargo stacks. The cargo stacks include a plurality of accumulated stacked goods, and multiple goods are stacked into multiple layers, and each layer The goods have multiple goods, and gaps are formed between the goods on the same layer.

[0063] The two-way cargo depalletizing equipment 10 includes a two-way depalletizing device 11 , a motion platform 13 , a cargo output line 12 , a cargo stack input line 14 , a cargo stack lifting mechanism 15 , an empty pallet recovery line...

no. 2 example

[0094] see Figure 5 In this embodiment, a two-way cargo depalletizing device 10 is provided, which can improve the depalletizing efficiency of cargo stacks. Wherein, the difference between the two-way cargo depalletizing equipment 10 provided in this embodiment and the two-way cargo depalletizing equipment 10 provided in the first embodiment is that in this embodiment, the moving platform 13 is replaced by a mechanical arm 17 .

[0095] In this embodiment, the two-way unpacking device 11 is installed at the end of the mechanical arm 17, so that the two-way unpacking device 11 is driven by the mechanical arm 17 to perform unstacking of goods. In addition, the visual recognition device 18 is electrically connected to the mechanical arm 17, so that the visual recognition device 18 can control the mechanical arm 17 to drive the two-way unpacking device 11 to depalletize the pallet according to the image information collected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com