Full-automatic unstacker

A destacker, fully automatic technology, applied in the direction of destacking of objects, conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity, heavy operation tasks, safety accidents, etc., to reduce labor intensity and safety. Risk, the effect of ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to describe the technical content, structural features, and achieved effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

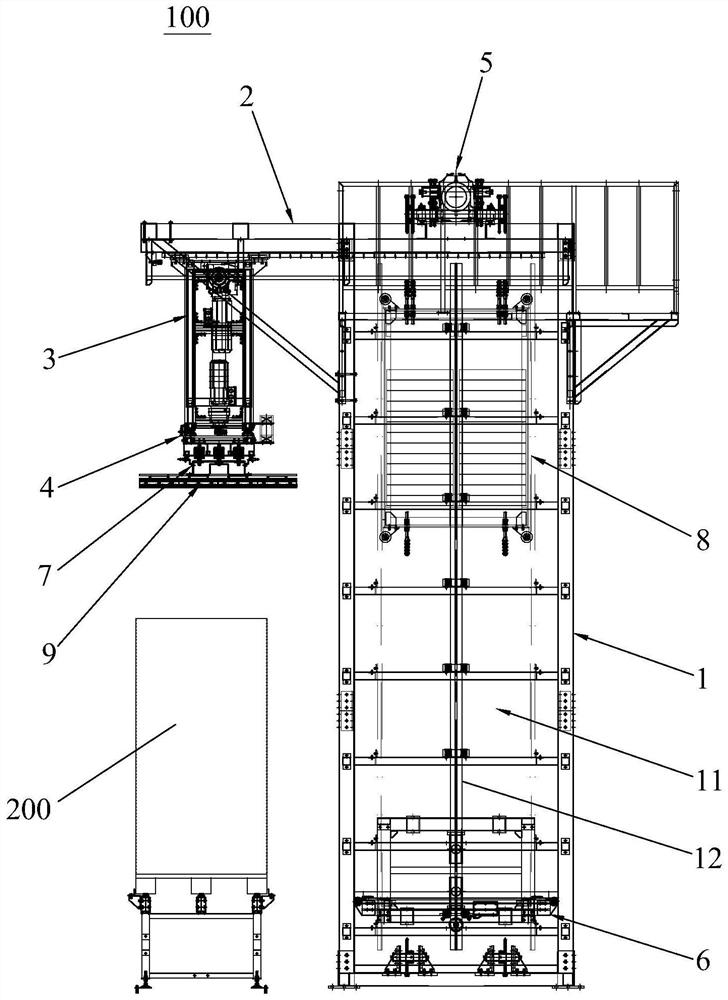

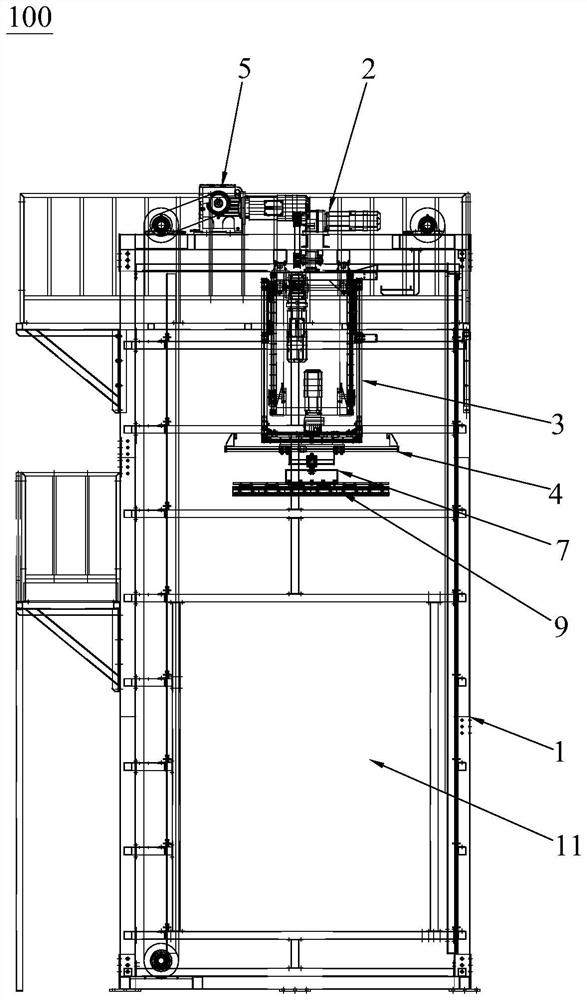

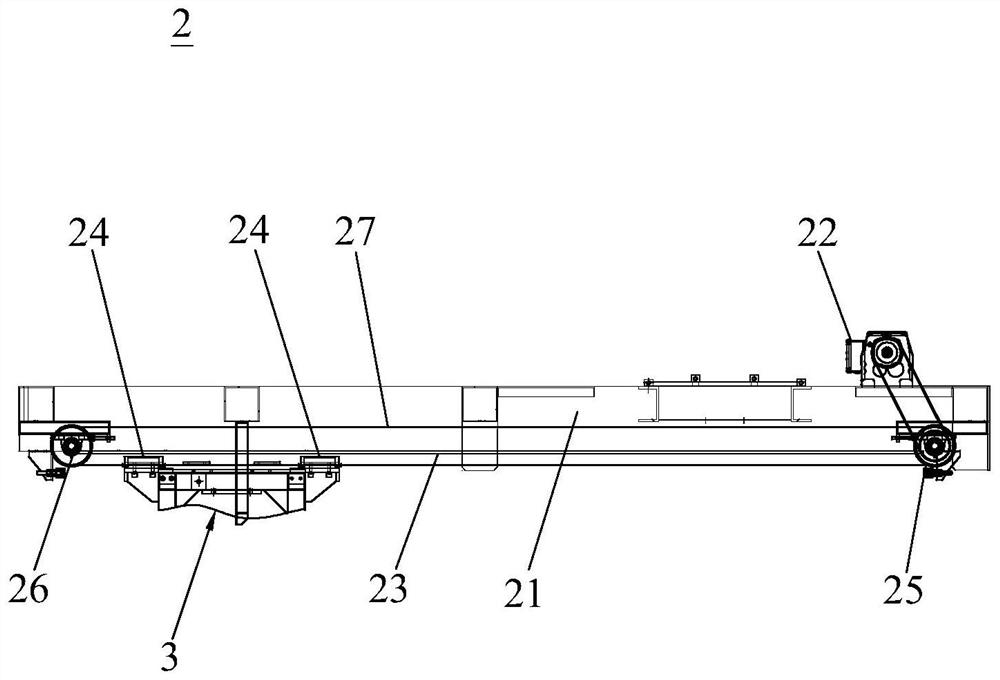

[0031] Such as Figure 1 to Figure 2 As shown, the fully automatic depalletizer 100 of the present invention includes a bracket 1, a transfer mechanism 2, a suction tool lifting mechanism 3, a translation mechanism 4, a lifting mechanism 5, an output mechanism 6, a suction tool 9, a visual system and a control system, and the The bracket 1 has an inner cavity 11 extending vertically. The suction device 9 is arranged at the output end of the translation mechanism 4 , and the suction device 9 communicates with the vacuum system. Under the vacuum of the vacuum system, the suction device 9 can hold the object 200 . The translation mechanism 4 is arranged on the output end of the sucker elevating mechanism 3; The top end is used to drive the suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com