Efficient body paper paving machine for foamed ceramic plate production

A foamed ceramic board, high-efficiency technology, used in ceramic molding machines, ceramic molding linings, conveyors, etc., can solve the problems of time-consuming and laborious, the bottom paper cannot be flatly laid on the bottom of the shed board, and the bottom paper is inefficient. achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

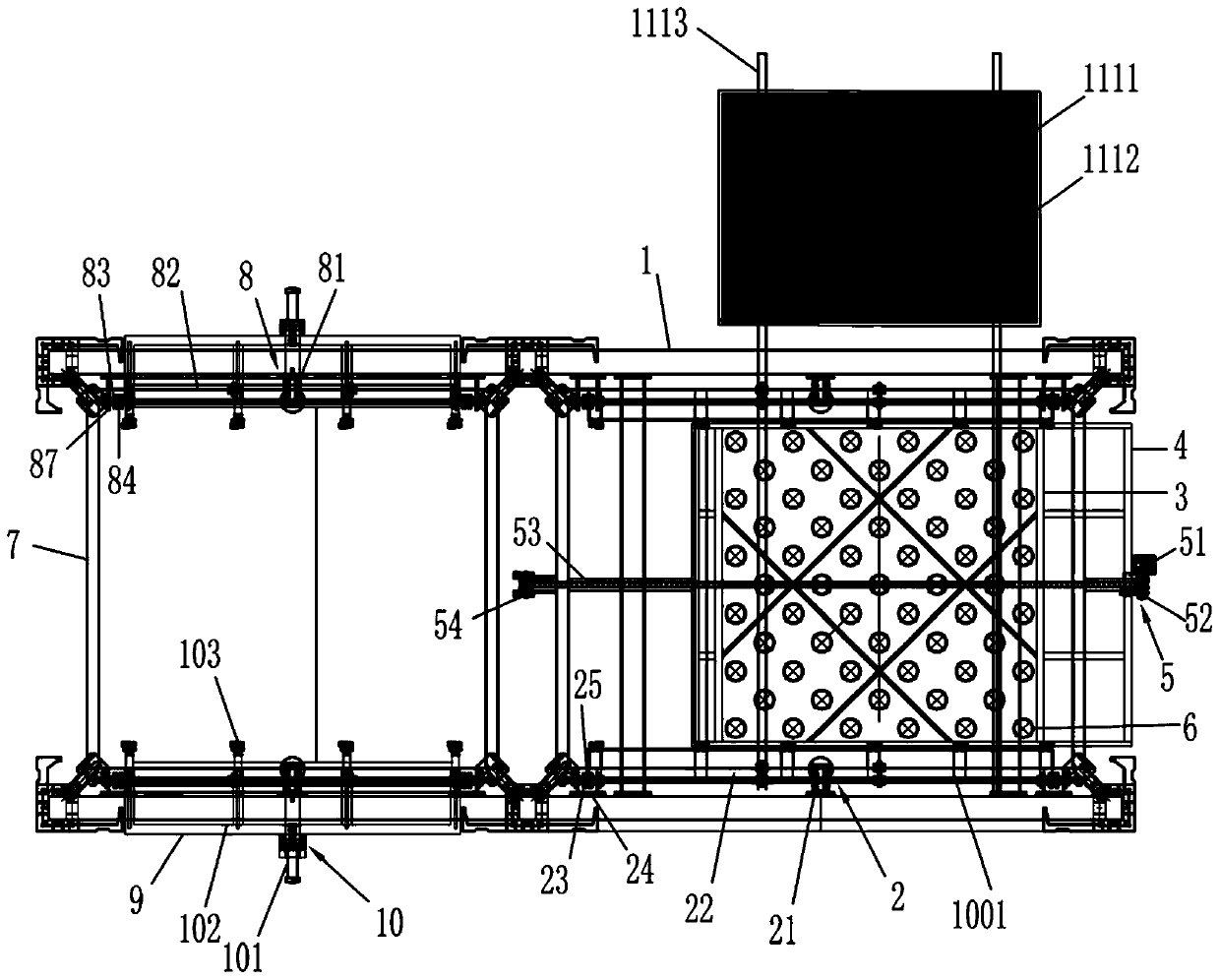

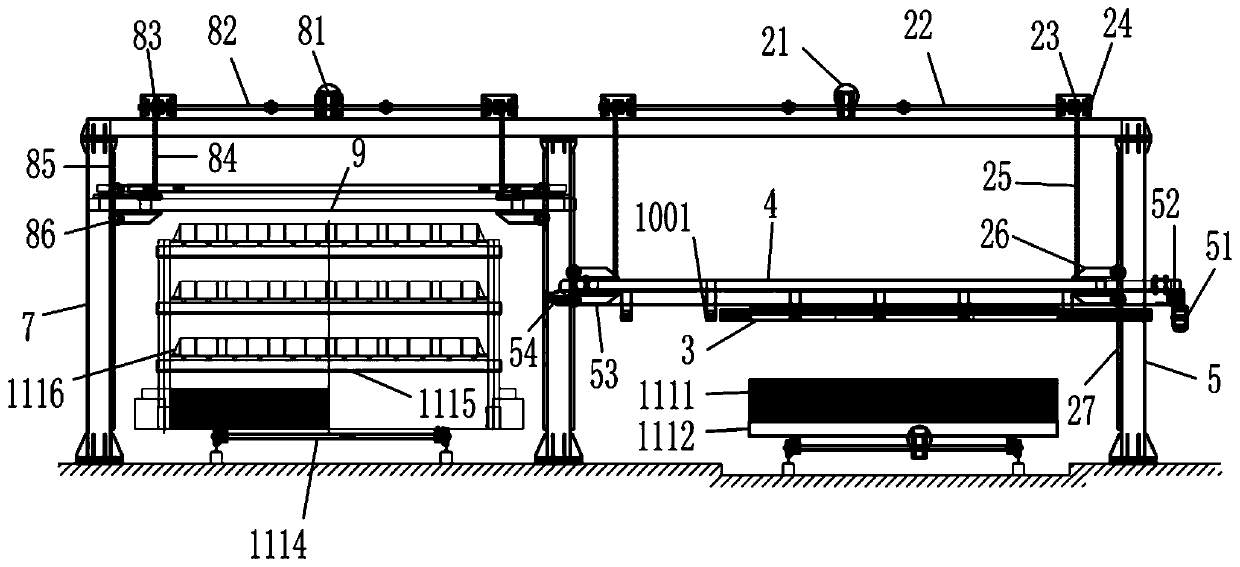

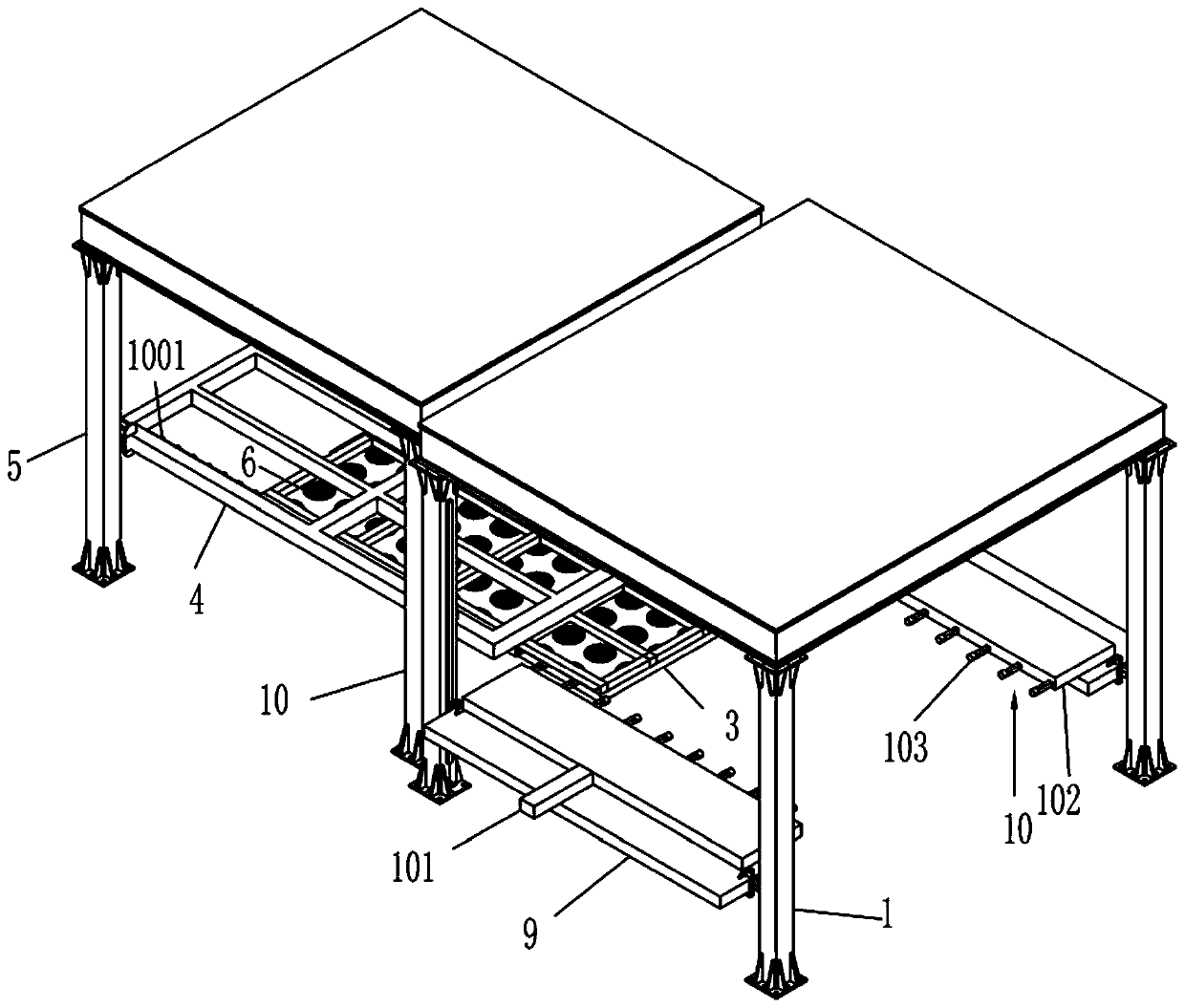

[0023] A high-efficiency base laying machine for the production of foamed ceramic plates, such as Figure 1-3 As shown, it includes a paper suction end frame 1, a paper suction end lifting mechanism 2, a paper suction tray 3, a paper suction end bracket 4, a paper feeding mechanism 5, a kiln car end frame 7, a kiln car end lifting mechanism 8, The kiln car end bracket 9 and telescopic wheel mechanism 10; the paper suction end frame 1 and the kiln car end frame 7 are all four-column structures, and the top of the paper suction end frame 1 is equipped with a paper suction end lifting mechanism 2, and the paper suction end There are two lifting mechanisms 2, the paper-absorbing end lifting mechanism 2 is arranged symmetrically about the central axis in the width direction of the paper-absorbing end frame 1, and the four end corners of the paper-absorbing end bracket 4 are connected to the output ends of the two paper-absorbing end lifting mechanisms 2 , the front and rear sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com