Building tubular pile based on wet land and preparation method thereof

A technology for pipe piles and construction, which is applied to the field of construction pipe piles based on wet soil and their preparation, can solve the problems of affecting the economic benefits of pipe piles, poor adaptability of pipe piles, waste of concrete resources, etc. Improve efficiency and reduce waste of human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

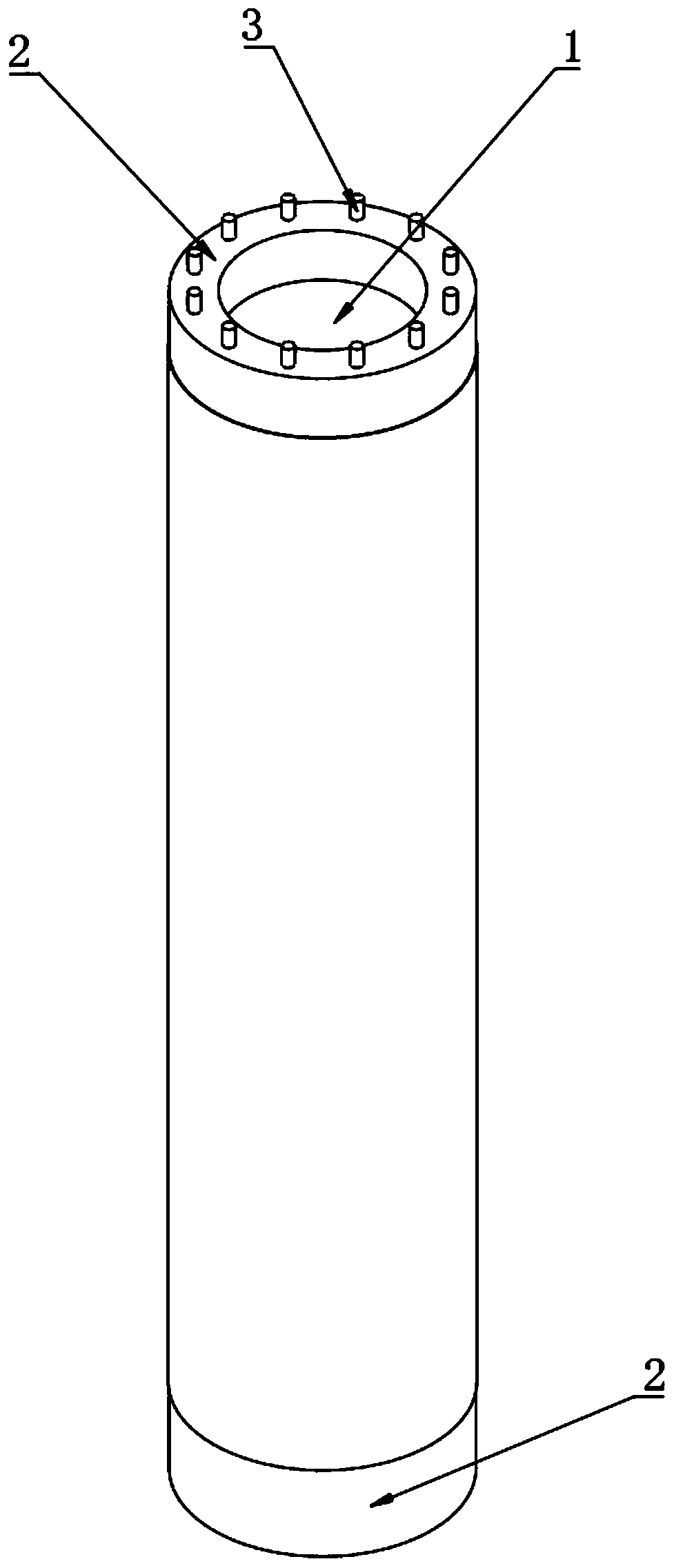

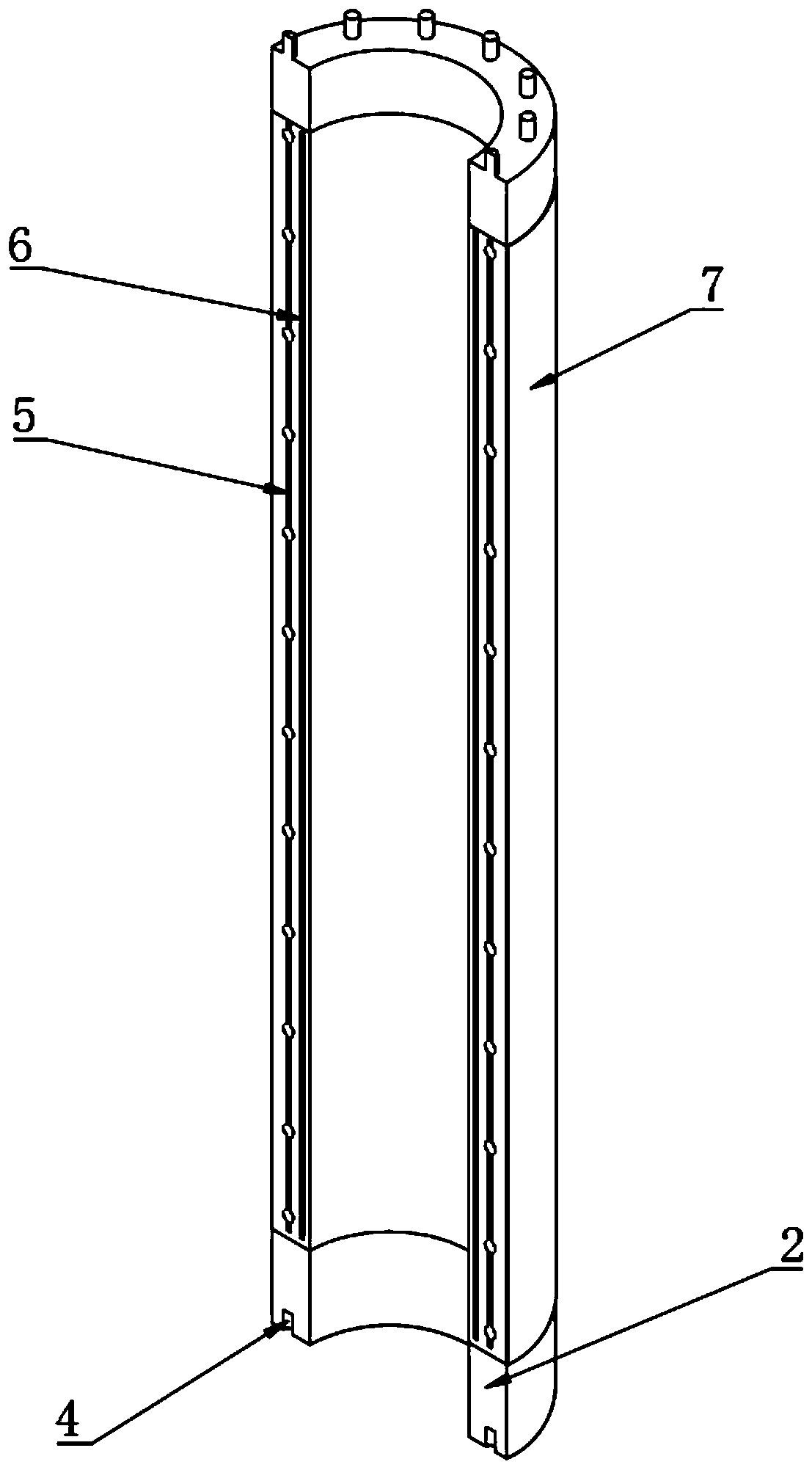

[0055] Embodiment 1: as Figure 1-2 As shown, the present invention provides a technical solution, a construction pipe pile based on wet land, comprising a pipe pile body 1, the top and bottom ends of the pipe pile body 1 are fixedly equipped with a pipe pile end 2, and the top pipe pile end The top of the head 2 is evenly embedded with a pipe pile connection bar 3, and the bottom of the bottom pipe pile head 2 is evenly provided with a pipe pile connection groove 4. The inside of the pipe pile body 1 is embedded with a steel cage 5, and the pipe pile body The interior of 1 is evenly embedded with reinforcing ribs 6 at the inner side of steel cage 5, and the outside of pipe pile body 1 is evenly coated with waterproof paint 7. Uniform one-to-one correspondence, the coating thickness of the waterproof coating 7 is 2 mm, which increases the waterproof performance of the pipe pile body 1 .

Embodiment 2

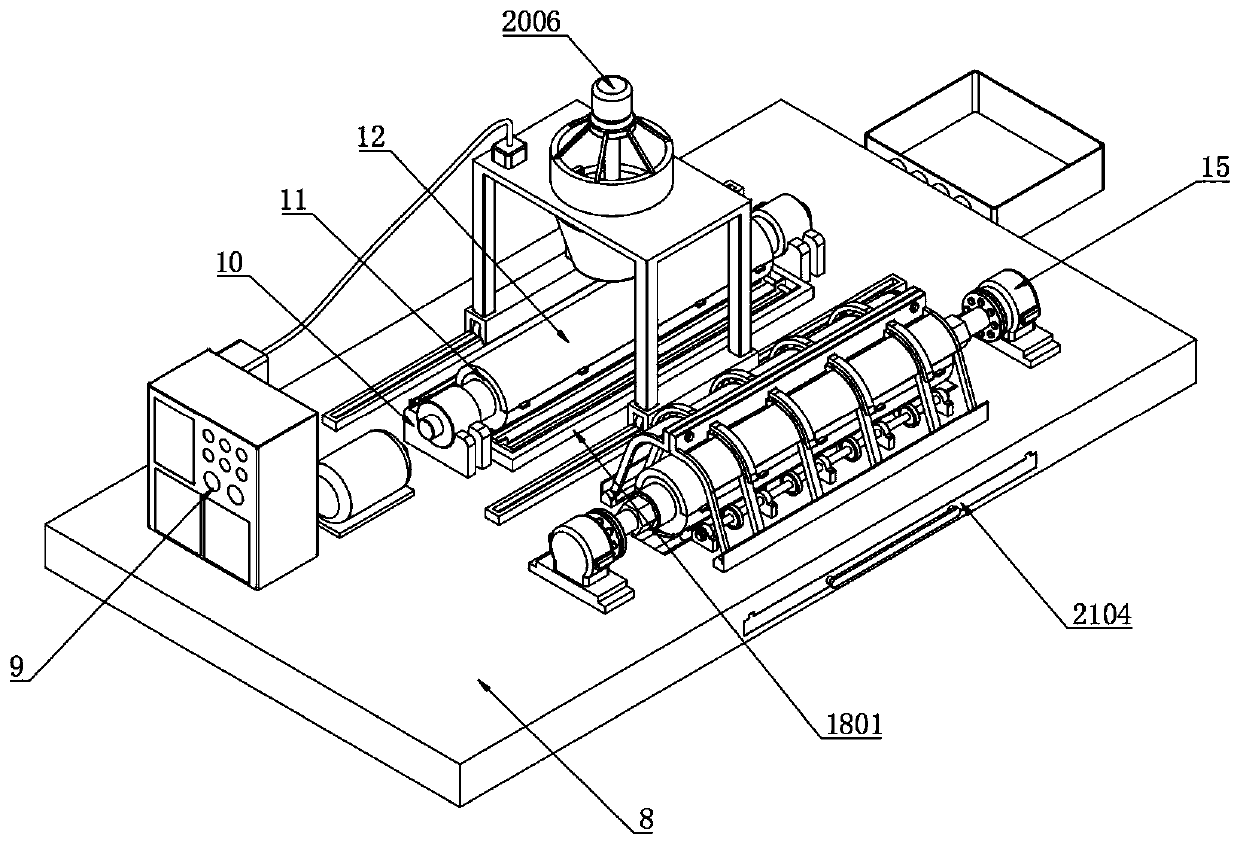

[0056] Embodiment 2: as Figure 3-17 As shown, the present invention provides a technical solution, a construction pipe pile preparation device based on wet land, including a base plate 8, a console 9 is fixedly installed on the top of the base plate 8, and the top of the base plate 8 is symmetrically fixed at a position corresponding to the side of the console 9 A steel mold base 10 is installed, the top of the steel mold base 10 is placed with a lower steel mold 11 installed, the top of the lower steel mold 11 is placed with a steel mold cover 12 installed, and the top of the base plate 8 is symmetrically connected to the positions on both sides of the steel mold base 10 There is a slide rail 13, the top of the slide rail 13 is slidably installed with a perfusion table 14, and the top of the base plate 8 is symmetrically fixed on one side of the slide rail 13. A pipe pile centrifuge 15 is installed between the two pipe pile centrifuges 15. Centrifugal steel mold 16, the top ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com