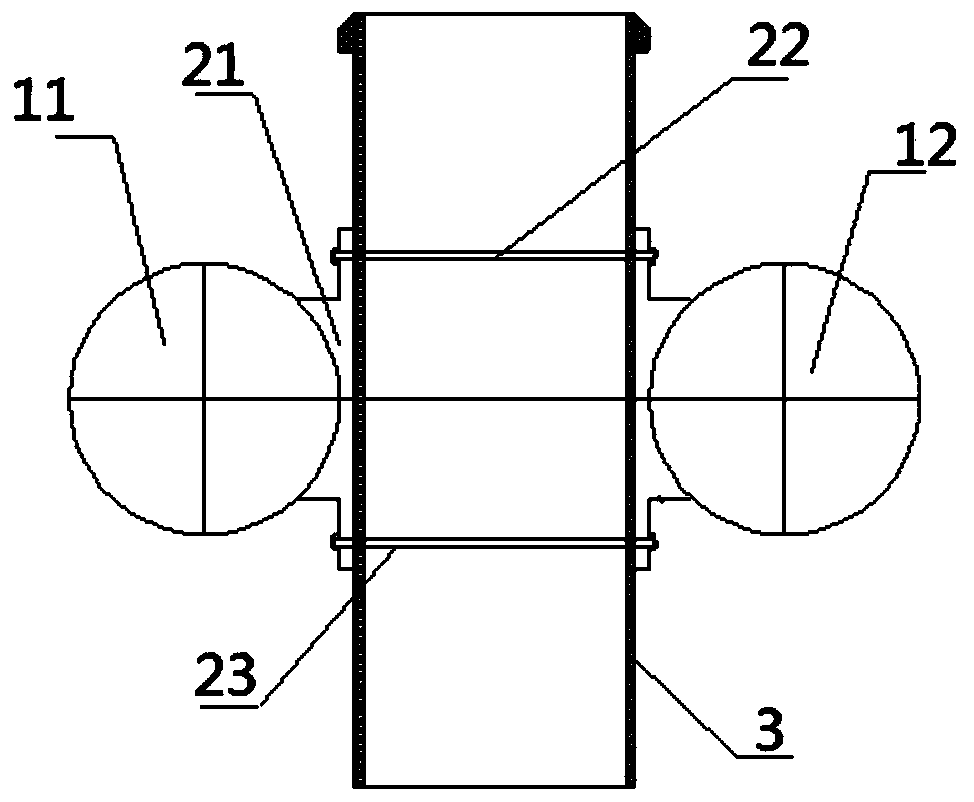

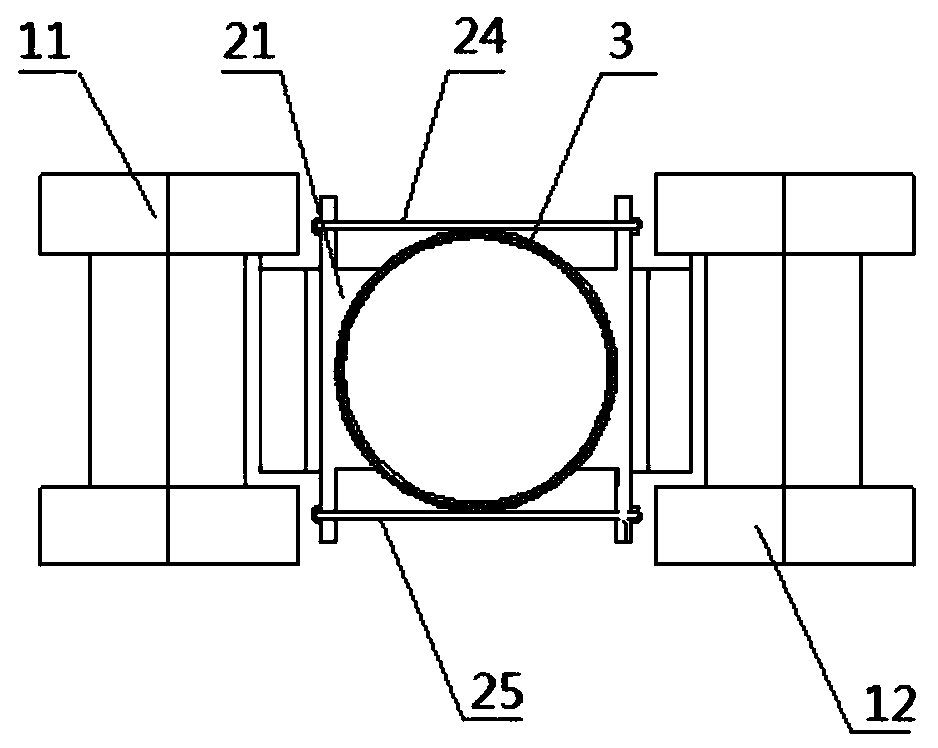

Cast-in-situ bored pile underwater concrete spouting and vibration construction method and device

A technology of underwater concrete and bored piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as low concrete strength, poor concrete compactness, and quality accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

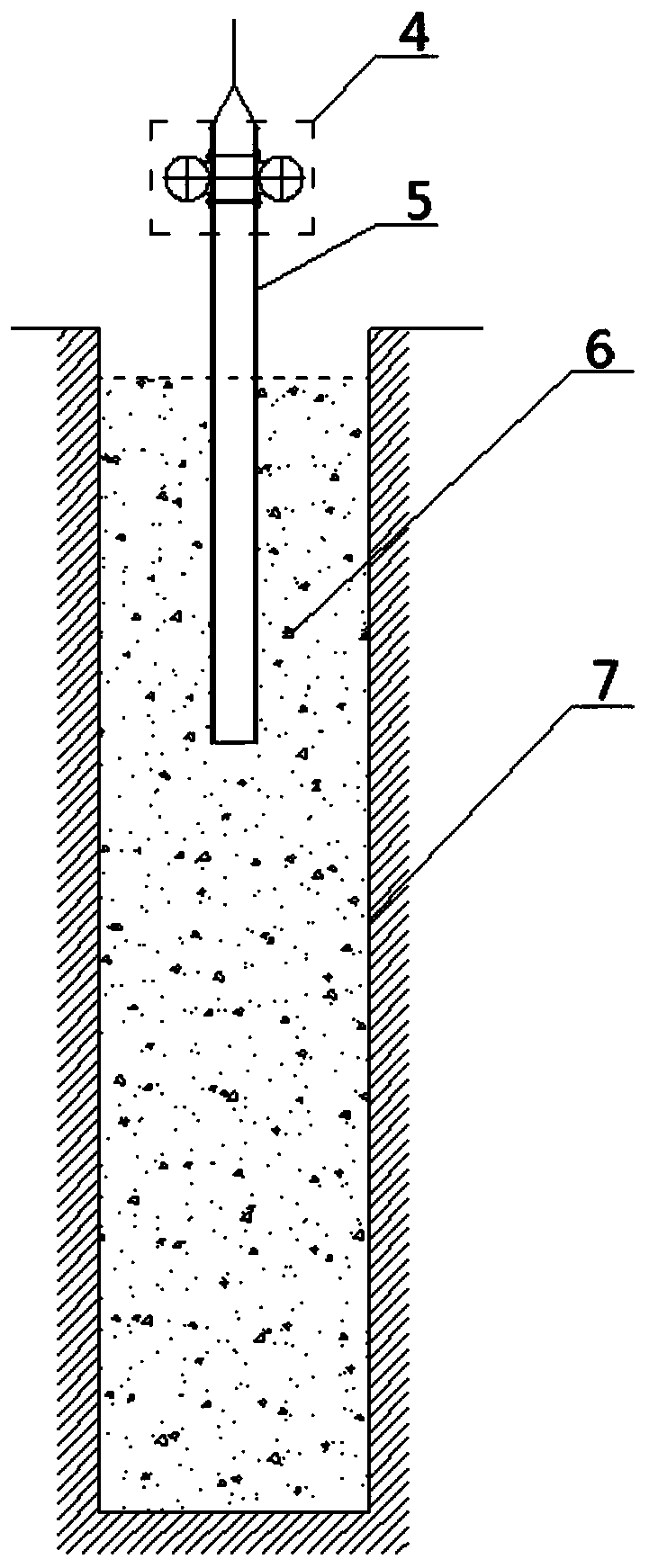

Embodiment 1

[0056] (1) Taking a power plant in Heyuan City, Guangdong Province as the construction object, the main structures such as the main factory building and boiler room are based on bored pile foundations. The designed pile diameter is 800mm, the pile length is 28.0m, and the bearing layer at the pile end is medium weathered sandstone. The design strength grade of the pile body concrete is C35. During the construction of the bored pile, a rotary drilling rig is used to form a hole in the mud retaining wall. The diameter of the hole is 800mm and the depth of the hole is 31.6m.

[0057] (2) Use the conduit method to pour concrete from the bottom of the pile hole to 0.8m above the design elevation of the pile top and stop pouring to obtain the unvibrated underwater concrete pile body 6. At this time, the length of the conduit retained in the pile hole is 6m. For the vibration depth of the pile body, a 6m conduit is added to the top of the conduit used for perfusion, so that the total ...

Embodiment 2

[0061] (1) Taking a power plant in Heyuan City, Guangdong Province as the construction object, the main structures such as the main factory building and the boiler room are based on bored cast-in-place piles. The designed pile diameter is 800mm, the pile length is 16.5m, and the bearing layer at the pile tip is medium weathered sandstone. The design strength grade of the pile body concrete is C35. During the construction of the bored pile, a rotary drilling rig is used to form a hole in the mud retaining wall. The diameter of the hole is 800mm and the depth of the hole is 20m.

[0062] (2) Use the conduit method to pour concrete from the bottom of the pile hole to 0.8m above the design elevation of the pile top and stop pouring to obtain the unvibrated underwater concrete pile body 6. At this time, the length of the conduit retained in the pile hole is 6m. For the vibration depth of the pile body, a 3m conduit is added to the top of the conduit used for perfusion, so that the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com