Air inlet mechanism used for piston compressor

A compressor and piston type technology, which is applied to the field of air intake mechanism for piston compressors, can solve the problems of reduced air intake speed, inability to meet the normal use of piston compressors, and low air compression of piston compressors, etc. Achieve the effect of preventing excessive temperature, improving heat dissipation and uniform air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

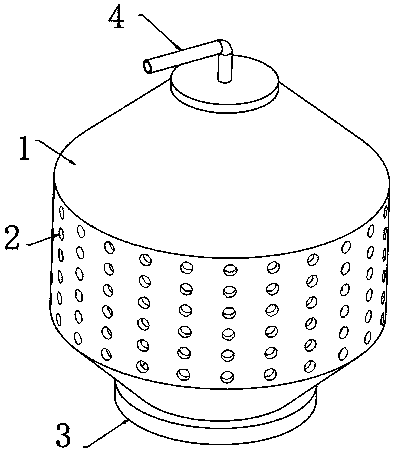

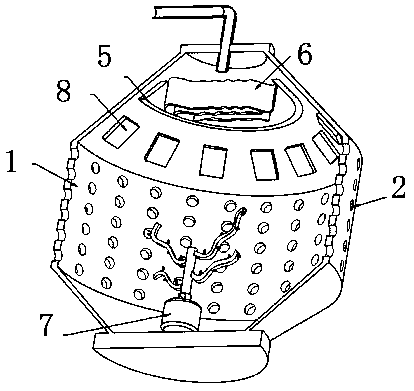

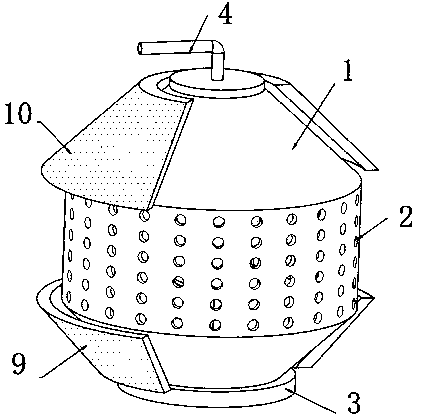

[0030] refer to Figure 1-4 , an air intake mechanism for a piston compressor, comprising an air intake box 1, the top outer wall of the air intake box 1 is connected with an air guide pipe 4 through a flange, and one side outer wall of the air intake box 1 is provided with equidistantly distributed air inlets 2 , the air inlet box 1 is a structure with two small ends and a large middle, the diameter of the air inlet 2 is between 3-6mm, and the air inlet 2 is located in the middle of the air inlet box 1, and the inner wall of one side of the air inlet box 1 is fixed by screws. The semiconductor refrigeration sheet 8, and the bottom inner wall of the air inlet box 1 is fixed with a motor 7 by screws, the output shaft of the motor 7 is connected with a rotating rod 12 through a coupling, and the outer wall of the rotating rod 12 is welded with irregularly distributed stirring rods 13, The stirring rod 13 has a wavy structure, and the wave shapes of the stirring rods 13 are diffe...

Embodiment 2

[0036] refer to Figure 5 , an air intake mechanism for a piston compressor. Compared with Embodiment 1, this embodiment also includes a second baffle 14 that is equidistantly fixed to the outer wall of one side of the first baffle 6 by screws. The second baffle The flow plate 14 is a zigzag structure.

[0037]Connect the device to the power supply, turn on the semiconductor cooling plate 8 to reduce the temperature value inside the air inlet box 1, resulting in a decrease in pressure, which can accelerate the speed of air flowing into the air inlet box 1, and increase the air intake in the same time, turn on the motor 7, and the motor 7 drives the rotation The rod 12 rotates, and the stirring rod 13 is a wavy structure with different shapes, which can generate vortices of different shapes. Mixing effect, cold air can cool down the interior of the piston compressor, effectively preventing the internal temperature of the piston compressor from being too high, the first dusty l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com