A drilling system and drilling method based on subsea pump pressure control

A subsea pump and drilling technology, which is used in underwater drilling, wellbore/well components, earth-moving drilling, etc., can solve the problems of high cost, consumption, and poor economic benefits of drilling rigs, and can solve the problems of narrow pressure window and enlarged density. range, the effect of reducing drilling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

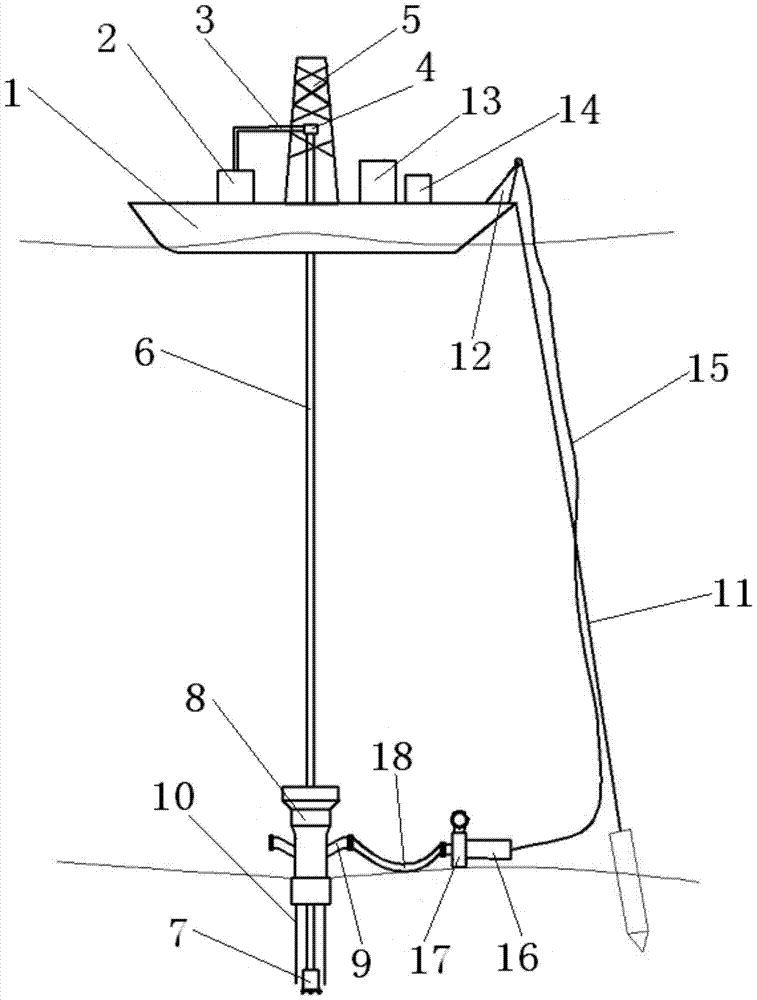

[0014] like figure 1 As shown, the present invention proposes a drilling system based on subsea pump pressure control, the system includes a drilling ship 1 arranged on the sea surface, a drilling fluid supply device 2 is arranged on the drilling ship 1, and the drilling fluid supply device 2 passes through A liquid manifold 3 is connected to a liquid inlet end of a faucet 4 . A derrick 5 is fixedly connected to the middle part of the drilling ship 1, and the swivel 4 is fixedly connected to the derrick 5. The liquid outlet end of the swivel 4 is rotatably connected to the top of a drill pipe 6, and a drill bit 7 is fastened to the bottom of the drill pipe 6. 6 rotates under the drive of a motor (not shown) fixedly connected on the derrick 5. A suction module 8 is sleeved on the bottom of the drill pipe 6, and the bottom of the suction module 8 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com