Fuel jet method

A fuel and nozzle technology, applied in the direction of fuel injection device, fuel injection control, charging system, etc., can solve the problems of incomplete combustion and large number of combustion chambers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following text, the working cycle is understood to mean the processes that occur during the operation of a reciprocating piston internal combustion engine, including valve actuation, combustion injection, combustion and discharge of combustion gases. In two-stroke machines, the working cycle is usually It is done between two revolutions in a four-stroke machine.

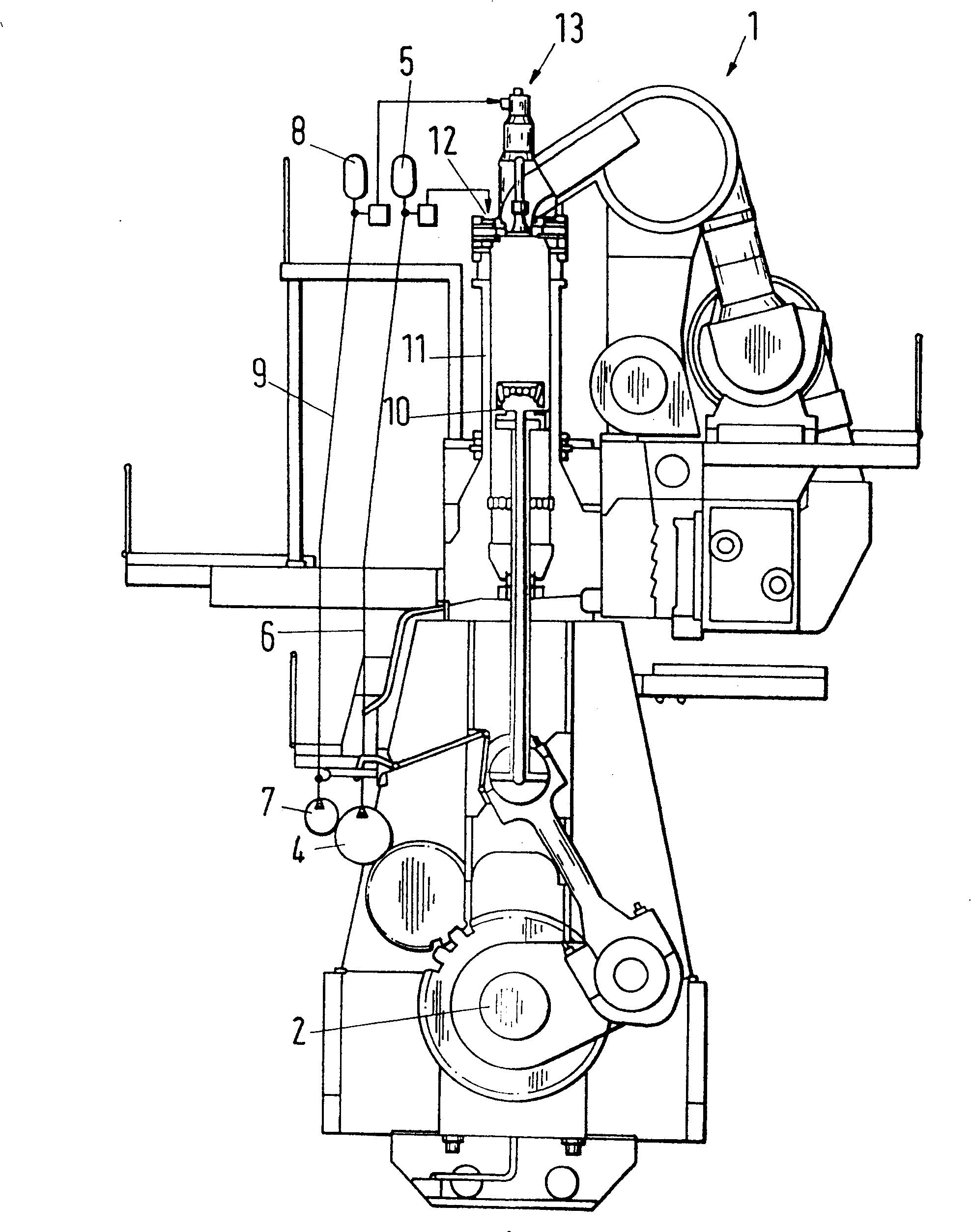

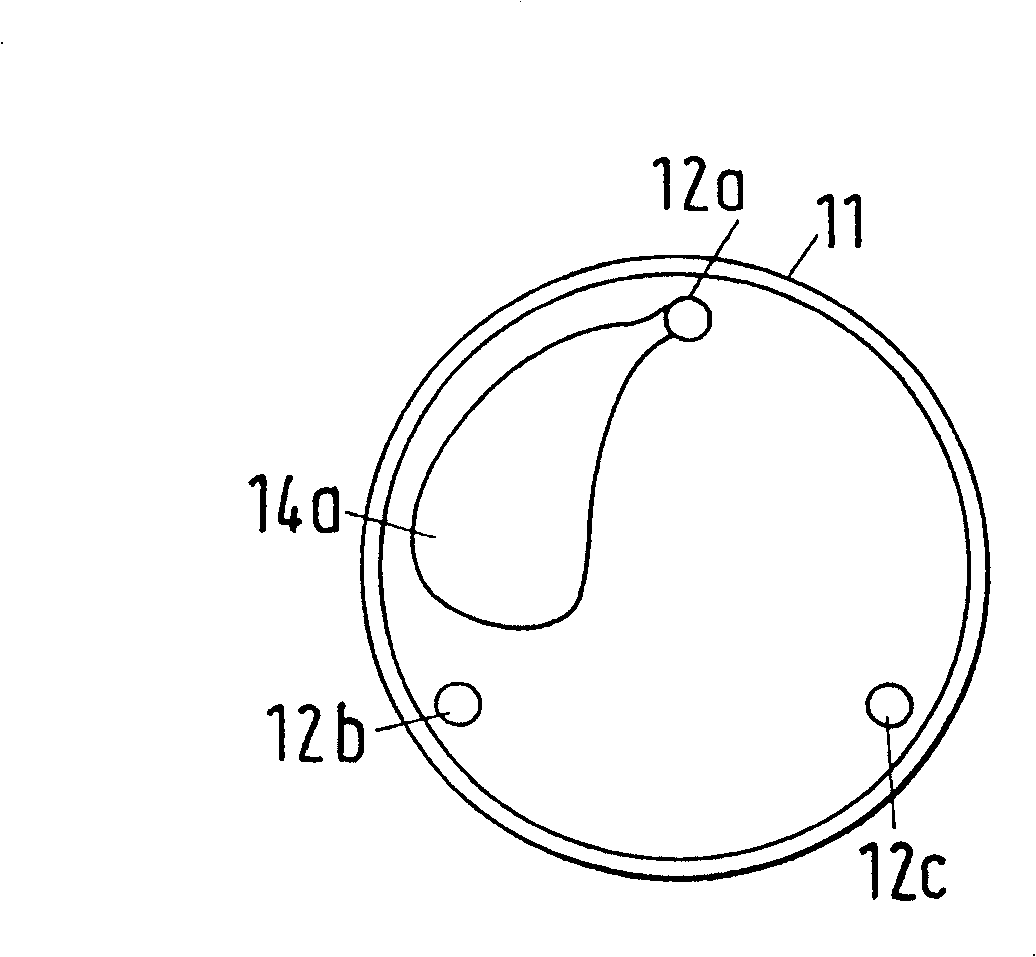

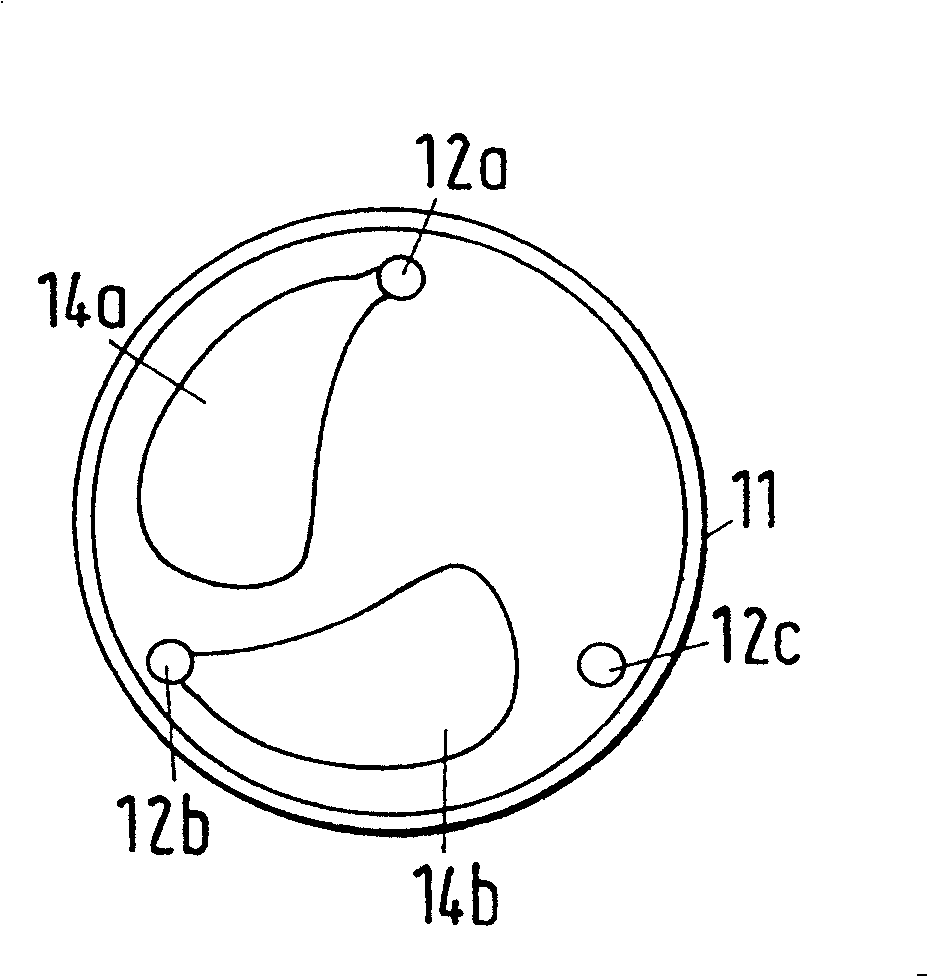

[0029] figure 1 A two-stroke diesel engine 1 is shown, with several cylinders 11 and pistons 10, wherein the interaction between the crankshaft 2, the combustion delivery and the movement of the exhaust valves 13 is electronically controlled. Fuel is delivered to the nozzles 12 by means of a high-pressure pump 4 via the line 6 and the pressure accumulator 5 . The hydraulic system comprising the pressure pump 7 , the pipeline 9 and the pressure accumulator 8 allows the positioning of the actuated exhaust valve 13 . The exhaust valve 13 and several nozzles 12 arranged in the center of the longitudinally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com