Down blowing water cooling extruder water ring device

A machine-water and water-cooling technology, which is applied in the field of water ring device of down-blown water-cooled extruder, can solve the problems of reduced cooling effect, low operating cost, adverse effects on film transparency, etc., and achieves improved transparency, enhanced cooling effect, production and operating costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

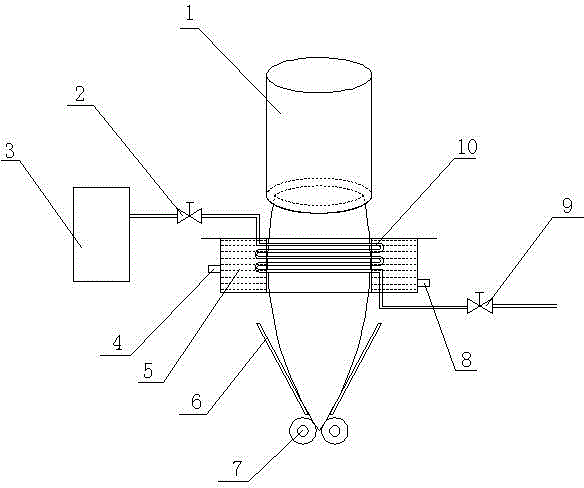

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] see figure 1 , an embodiment of a water ring device for a down-blowing water-cooled extruder of the present invention, a water ring 5 composed of an annular outer wall, an annular inner wall and a bottom surface, a purified water inlet 4 and a purified water outlet 8 on the annular outer wall of the water ring 5. Above the water ring 5 is the membrane head 1 , and below the water ring 5 there is a herringbone plate 6 and the first traction 7 .

[0018] An air conditioner coil 10 is arranged in the water ring 5. The air conditioner coil 10 has two ports as an outlet port and an inlet port. An air conditioner 3 is configured for the air conditioner coil 10. The air conditioner 3 has a cooling capacity of 5P or more. The outlet end of the air conditioning coil 10 is connected to the compressor of the air conditioner 3, and the inlet end is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com