Cyclic cooling device for water for carbon fiber surface sizing agent content measuring

A technology of circulating cooling and carbon fiber, which is applied in the field of carbon fiber manufacturing, can solve the problems of no recycling device, etc., and achieve the effects of easy management, recycling, and water saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

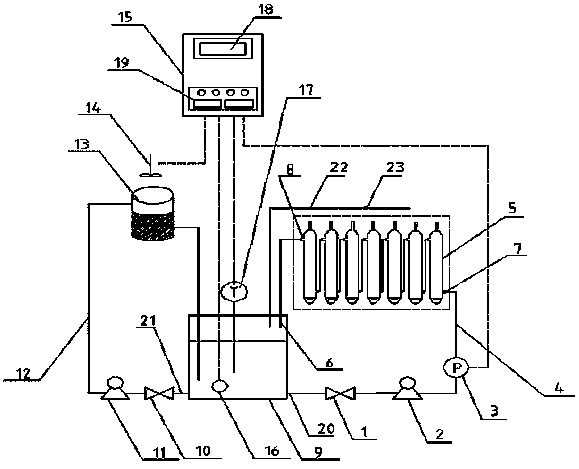

[0010] exist figure 1 Among them, the present invention is provided with a circulating water tank 9, and the circulating water tank outlet A20 of the circulating water tank 9 enters the condensing device 5 connected in series through the manual valve A1, the circulating water pump 2, the pipeline A4, and the water inlet 7 of the condensing device, and the condensing device The water outlet 8 returns to the circulating water tank 9 through the pipeline A return water outlet 6, and the pressure sensor 3 is installed in the pipeline A4, the pressure sensor 3 is connected to the signal input terminal of the programmable controller, and the signal output terminal of the programmable controller is connected to The frequency converter controls the rotating speed of the circulating water pump 2; a temperature sensor 17 is installed in the circulating water tank 9, the temperature sensor 17 is connected to the signal input terminal of the programmable controller, and the signal output t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com