Sampling circuit for electromagnetic heating product

A technology of sampling circuit and power circuit, which is applied in the electronic field, can solve the problems of high manufacturing cost, complex circuit, easy to generate parasitic inductance, etc., and achieve the effect of improving production and use efficiency, strong anti-interference ability, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A sampling circuit for electromagnetic heating products of the present invention will be described with reference to the accompanying drawings.

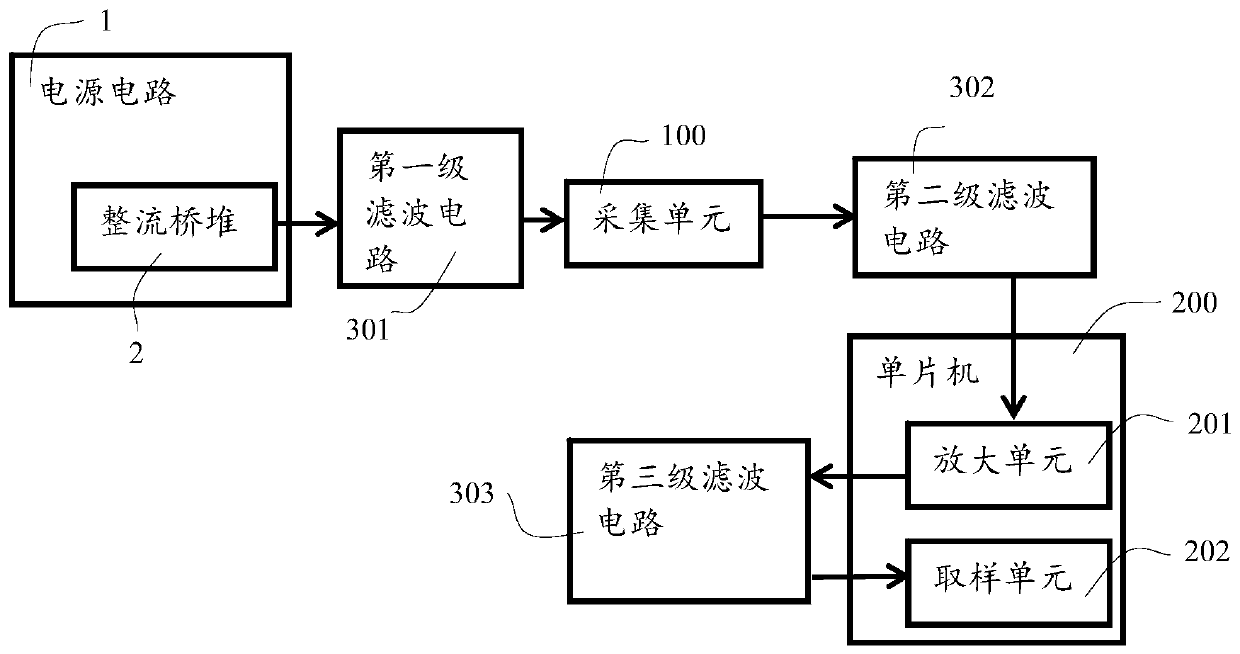

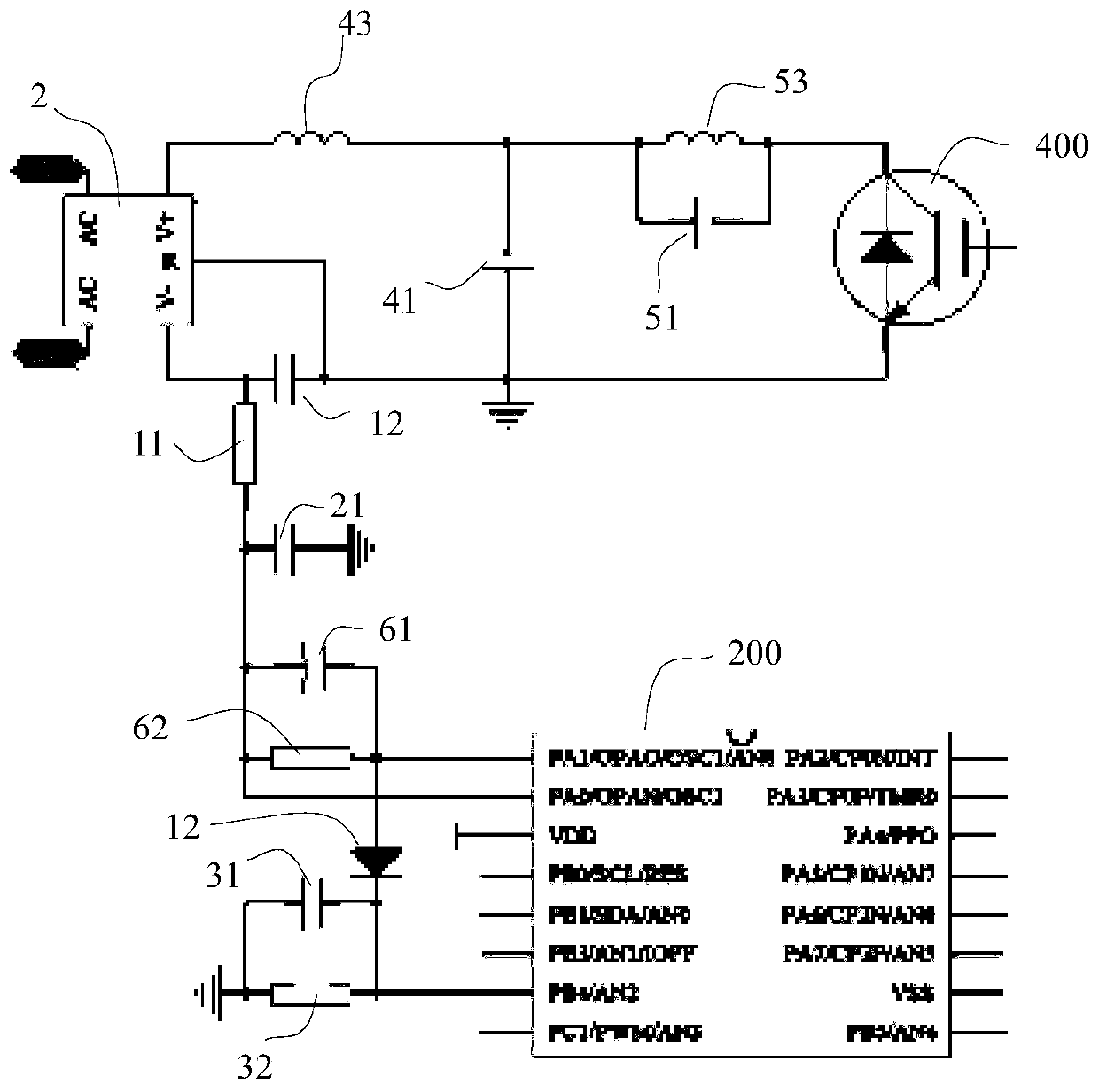

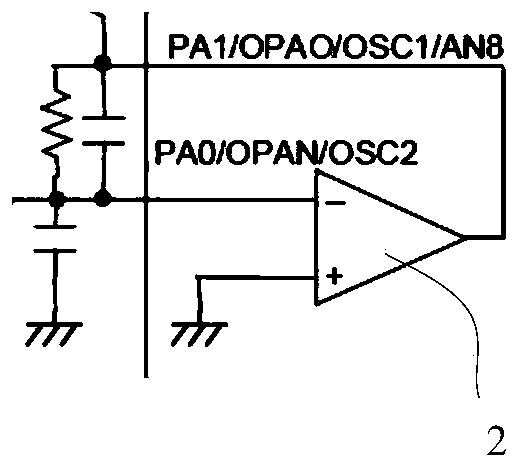

[0022] Such as Figure 1 to Figure 2 As shown, a sampling circuit for electromagnetic heating products includes a power supply circuit 1 for providing a DC output by using a rectifier bridge stack 2, and also includes a collection unit 100 connected to the power supply circuit 1, and The acquisition unit 100 outputs sampling signals; the single-chip microcomputer 200, the single-chip 200 integrates an amplifying unit 201, the amplifying unit 201 is connected to the acquisition unit 100, the amplifying unit 201 amplifies the output signal of the acquisition unit 100, and the The amplifying unit 201 includes an inverting amplifier; a sampling unit 202, the sampling unit 202 is connected to the amplifying unit 201, the sampling unit 202 performs sampling processing on the acquisition unit 100; a filtering unit, the filtering unit in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com