Single-machine automatic alignment calculation-point-free machining method

A processing method, automatic technology, applied in the direction of instruments, digital control, control/regulation systems, etc., can solve problems such as error-prone efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

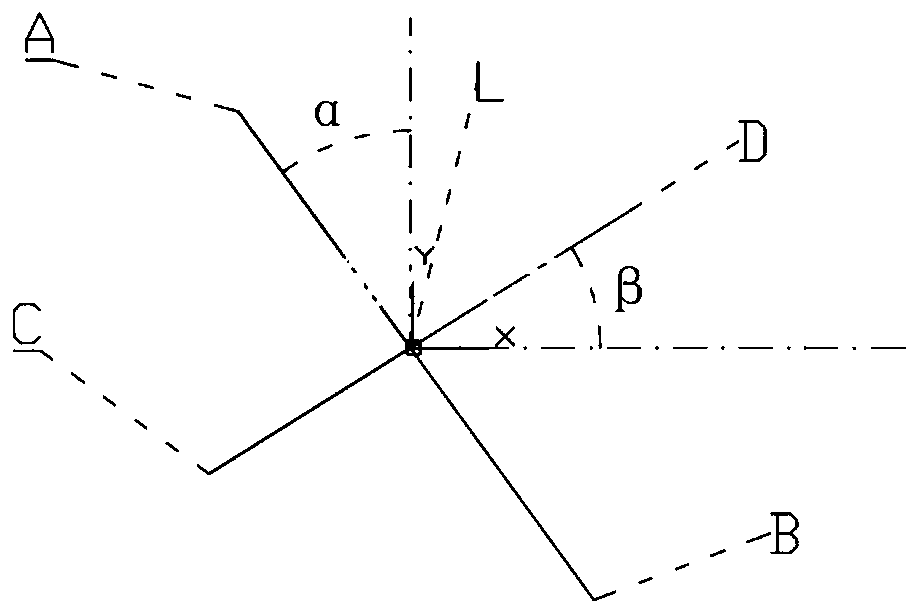

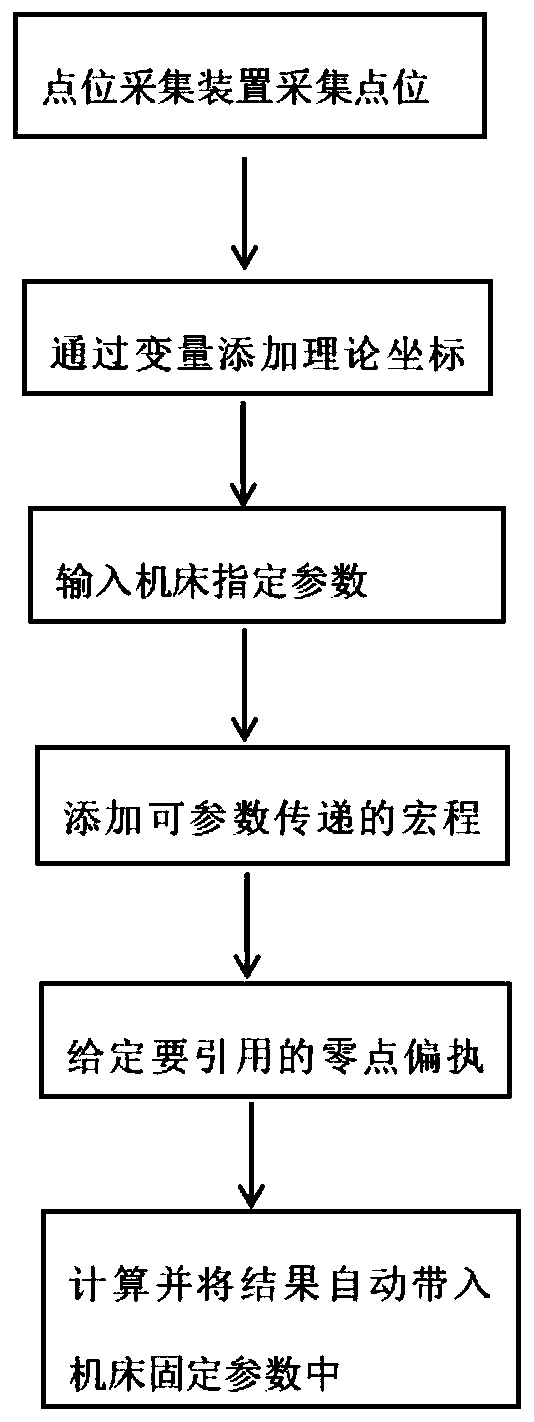

[0038] Use needles and other collection tools to collect points on the two lines of the blank. Y+ direction point input G55, Y-direction point input G56 X+ direction point input G57 X-direction point input G58

[0039] L805

[0040] ;%

[0041] ; MAOPEI

[0042] R1=$P_UIFR[2,X,TR]; 2x point data extraction

[0043] R2=$P_UIFR[2,y,TR]; 2y

[0044] R3=$P_UIFR[3,X,TR]; 3x

[0045] R4=$P_UIFR[3,y,TR]; 3y

[0046] R5 = $P_UIFR[4,X,TR]; 4x

[0047] R6=$P_UIFR[4,y,TR]; 4y

[0048] R7=$P_UIFR[5,X,TR]; 5x

[0049] R8=$P_UIFR[5,y,TR]; 5y point data extraction

[0050] R9=R5-R7

[0051] R10=R2*R3-R4*R1 The calculation formula is relatively long, and part of the data is decomposed and calculated

[0052] R11=R1-R3

[0053] R12=R8*R5-R6*R7

[0054] R13=R2-R4

[0055] R14=R4*(R7-R5)

[0056] R15=R6*(R3-R7)

[0057] R16=R8*(R5-R3)

[0058] R17=(R4-R2)*(R7-R5)-(R8-R6)*(R3-R1)

[0059] R18=(R9*R10+R11*R12) / R17 calculates the X coordinate of the center intersection point

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com