Single-machine calculation-point-free automatic alignment machining method

A processing method and stand-alone technology, applied in computer control, instruments, simulators, etc., can solve problems such as error-prone efficiency, and achieve the effects of saving time, reducing error rate, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

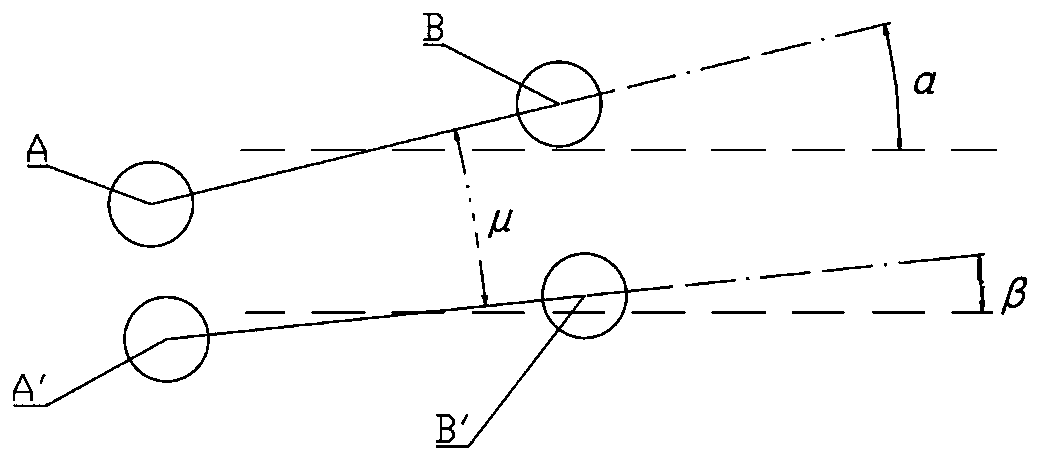

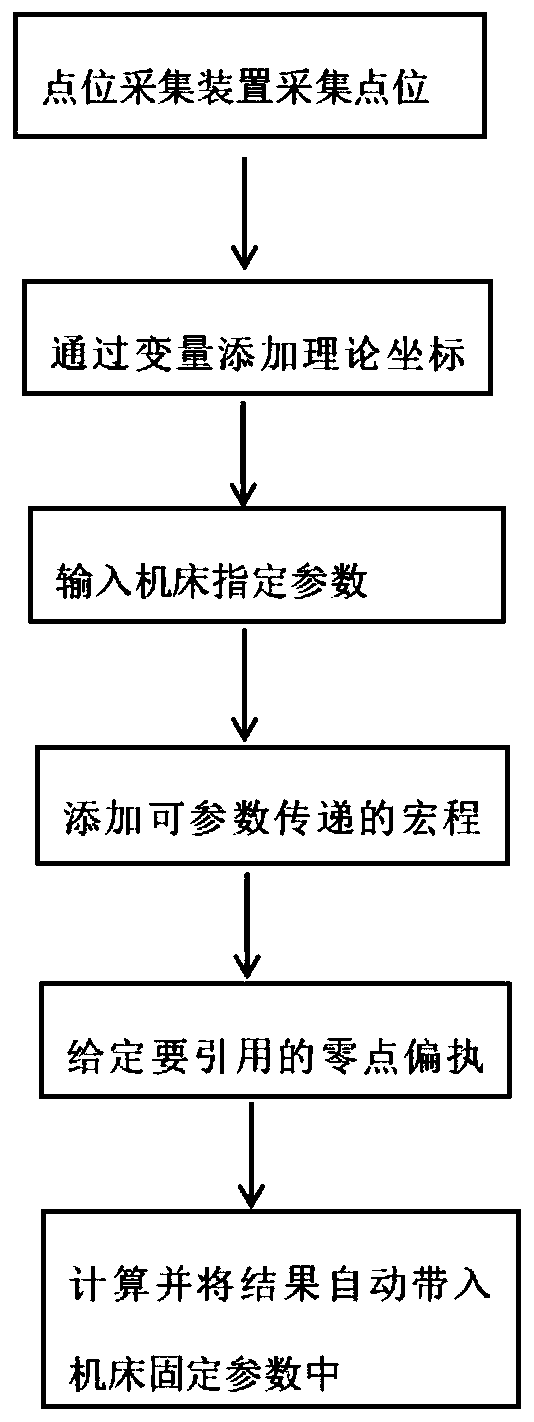

[0052] First move the probe to the approximate middle position of the hole to be aligned

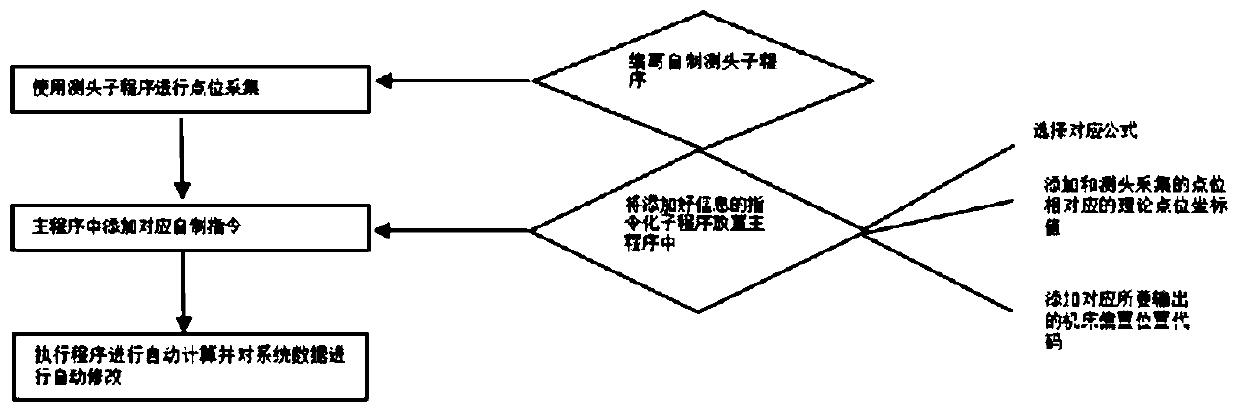

[0053] Call the self-made probe program in MDI

[0054] Siemens system:

[0055] Extern L910 (REAL, REAL, REAL)

[0056] L910 (measure diameter, speed, input offset zero)

[0057] Then measure two points. For example, the first point A is input to G54 and the second point is input to G55. The measured aperture is 50, and the speed is 100.

[0058] Then the two-stage measurement procedure is

[0059] L910(50,100,1)

[0060] L910(50,100,2)

[0061] The self-made subroutine executed in the background is as follows:

[0062] PROC L910 (REAL CRD, REAL JGF, REAL LDG) SAVE defines subroutine parameters

[0063] R2=CRD; celiang banjing assigns value to variable

[0064] R3=JGF; sudu assigns value to variable

[0065] R4=LDG; lingdian assigns value to variable

[0066] R2=R2 / 2 assigns value to variable

[0067] R60=$AA_IM[X] Use system variables to extract the current coordinates

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com