General speed line steel rail use state evaluation method

A state evaluation and rail technology, applied in the direction of track, road, track maintenance, etc., can solve the problem of low completion of normal-speed line grinding operations, achieve the effect of optimizing planning arrangements and improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

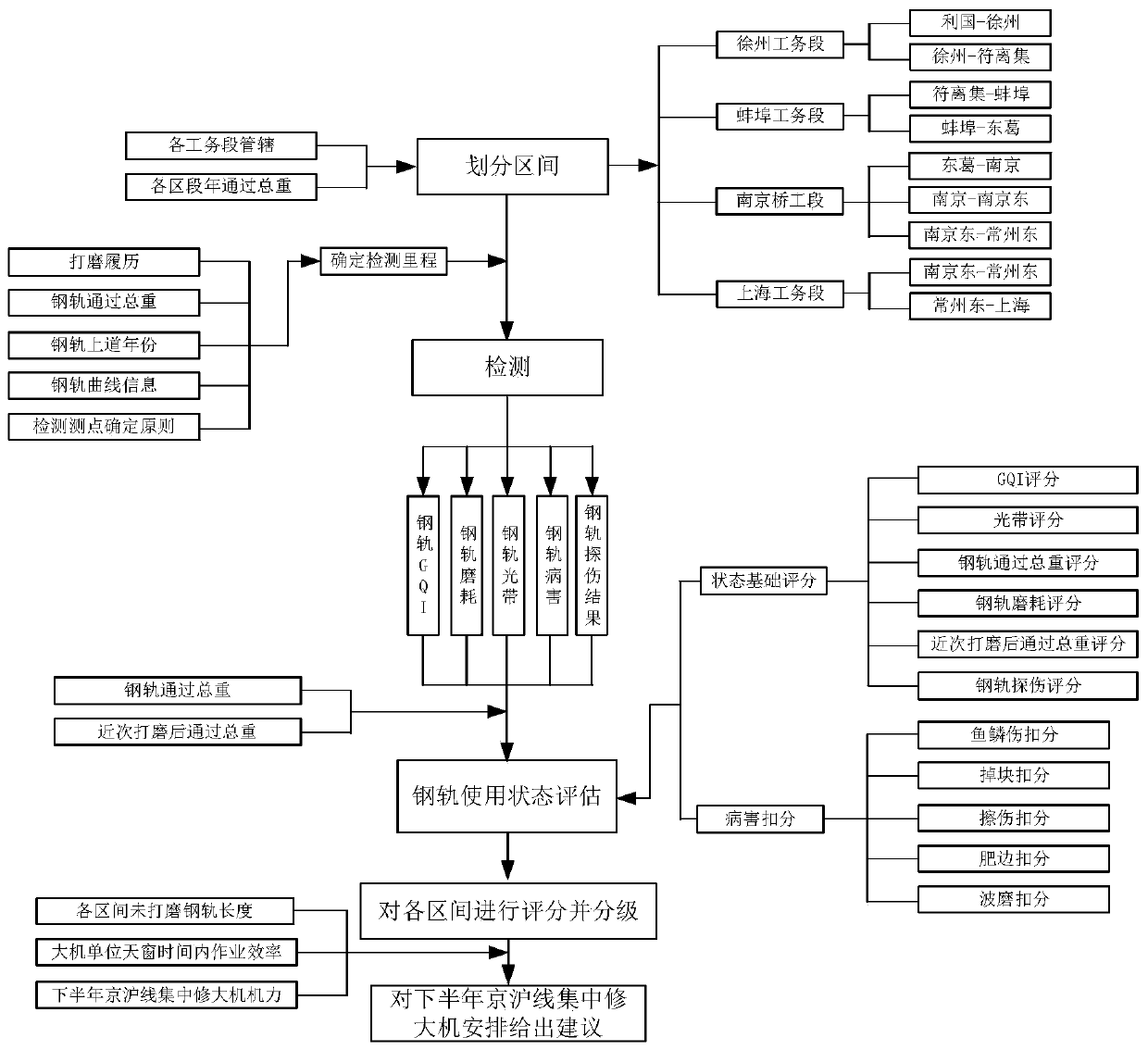

[0084] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0085] The present invention provides a method for assessing the state of use of a common-speed line rail, which is specifically implemented through the following steps:

[0086] Step 1: Divide the measurement interval according to the different jurisdictions of each public works section and the total annual traffic volume.

[0087] During the division process, it is necessary to weigh the total annual rail throughput and the responsible areas of different public works sections, and divide the rails with the same or similar annual total throughput (with a difference of 10Mt) within the jurisdiction of the same public works section into one section. For example, according to different jurisdictions, it is divided into Xuzhou, Bengbu, Nanjing and Shanghai public works sections, and according to the traffic volume, the jurisdiction of Xuzhou public works section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com