Self-calibration soft start circuit of buck converter

A technology of soft start circuit and step-down converter, which is applied in the field of power supply, can solve the problems of limited load capacity, large voltage difference, and the failure of BUCK chip to output, etc., and achieve the effect of high safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

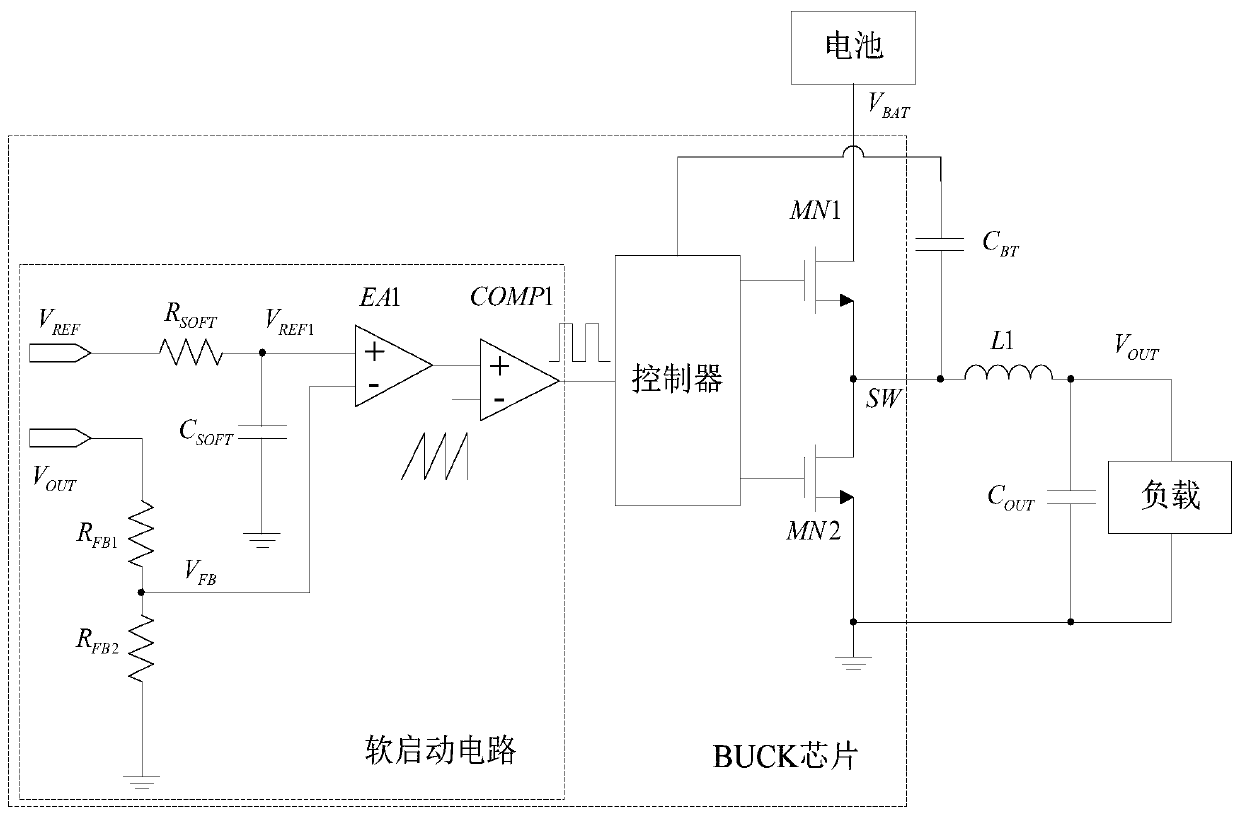

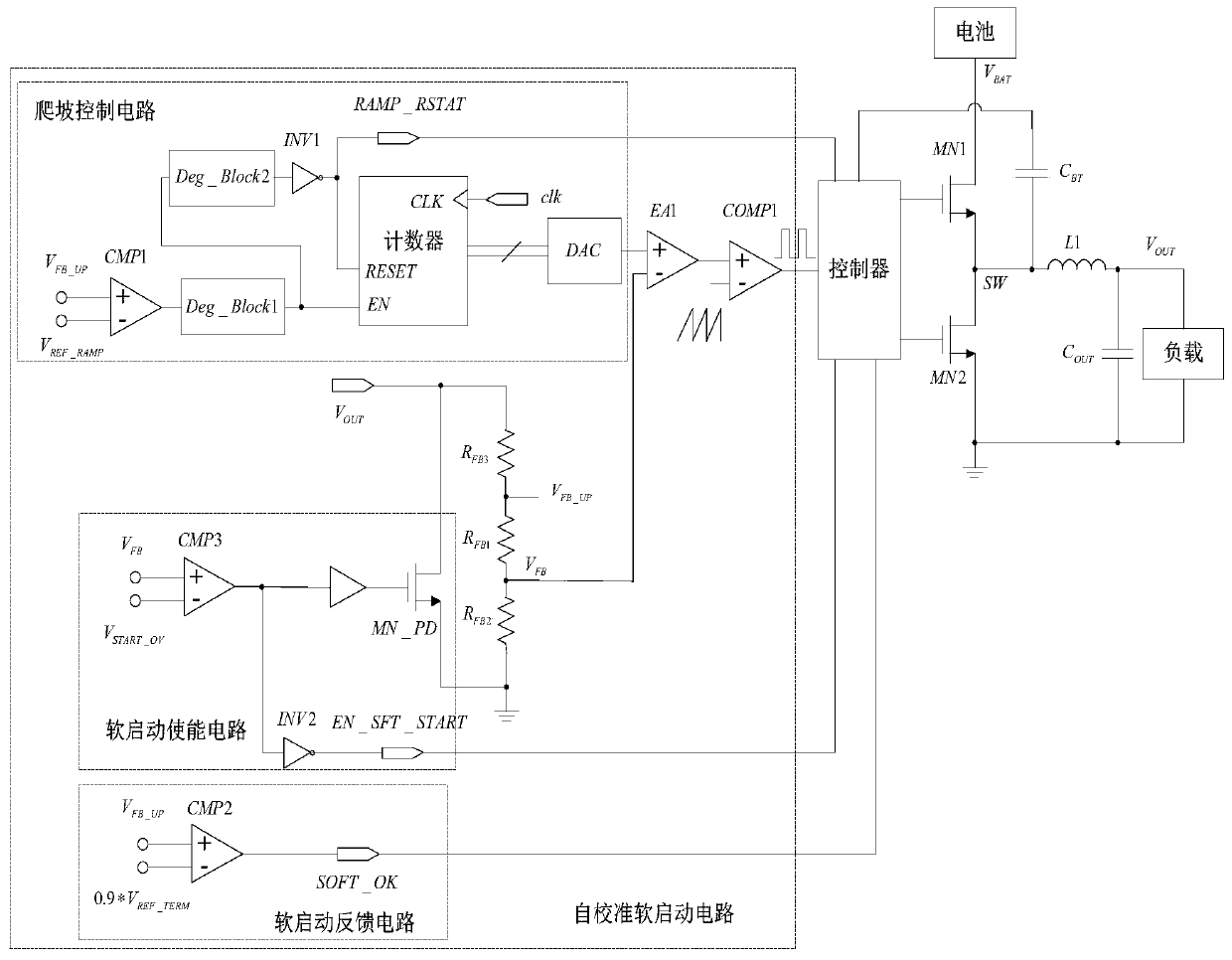

[0021] This application discloses a self-calibrating soft-start circuit for a buck converter. The rest of the internal circuits of the buck converter and the connection relationship with the external battery and load can be referred to figure 1 and other existing technologies, this application will not introduce in detail, only the self-calibration soft-start circuit part will be introduced. Please refer to figure 2 , the self-calibration soft-start circuit includes an error amplifier EA1, a PWM comparator COMP1, a voltage divider circuit and a ramp control circuit. One end of the voltage divider circuit is connected to the output end of the step-down converter to obtain the output voltage V OUT , and the other end is grounded, and the voltage dividing feedback end of the voltage dividing circuit is connected to the inverting input end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com